Parker EME

Introduction

192-120148N5 June 2011

17

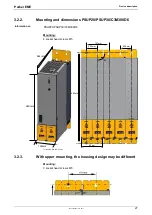

2.7.1.2

Conditions of utilization for cables / motor filter

Operation of the devices only with motor and feedback cables whose plugs

contain a special full surface area screening.

<80m per axis (the cable must not be rolled up!)

The entire length of the motor cable per axis combination may not exceed 300m.

A motor output filter is required for motor cables >20 m:

MDR01/04 (max. 6.3 A rated motor current)

MDR01/01 (max. 16 A rated motor current)

MDR01/02 (max. 30 A rated motor current)

Shielding connection of the motor cable

The cable must be fully-

screened and connected to the Compax3 housing. Use the

cable clamps/shield connecting terminals furnished with the device.

The shield of the cable must also be connected with the motor housing. The fixing

(via plug or screw in the terminal box) depends on the motor type.

< 80m

Corresponding to the specifications of the terminal clamp with a temperature range

of up to 60°C.

Signal lines and power lines should be installed as far apart as possible.

Signal lines should never pass close to excessive sources of interference

(motors, transformers, contactors etc.).

Do not place mains filter output cable parallel to the load cable.

2.7.1.3

Additional conditions of utilization

Operation with standard motors.

Use only with aligned cont

roller (to avoid control loop oscillation).

Connect the filter housing and the device to the cabinet frame, making sure that the

contact area is adequate and that the connection has low resistance and low

inductance.

Never mount the filter housing and the device on paint-coated surfaces!

Make sure to use only the accessories recommended by Parker

Connect all cable shields at both ends, ensuring large contact areas!

Motor and Feedback

cable:

Compax3M motor

cable

Compax3M encoder

cable:

Cable

Cable installation:

Motors:

Control:

Grounding:

Accessories: