8

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

Axial Piston Pump

Series PV, series 47 and higher

Bulletin MSG30-3245-INST/UK

Installation manual

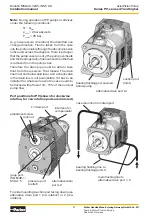

4. Standard pressure compensator with D03 interface, code ...MM1

The standard pressure compensator code ...MM1

has topside an NG6/Cetop 3/NFPA D03 interface

for the mounting of suitable pilot valves. This com-

pensator can for example be directly equipped

with a proportional pressure pilot valve for electri-

cal pressure setting (ordering code ...MMK, see

figure on page 10).

The pilot valve must be capable of pilot flows of ap-

prox. 1,2 l/min. Therefore a nominal flow range of

3 – 6 l/min is recommended. A too small as well

as a too large pilot valve can lead to unsatisfactory

compensator performance.

In addition the compensator can be equipped with

a directional control valve for stand-by (unload-

ing) functions (ordering code ...MMW, see figure

on page 10).

Please note:

when mounting accessories (e.g.:

proportional pressure pilot valve) or external (re-

mote) control the integrated pilot valve first must

be turned in to avoid too early pressure limitation.

interface NG6 DIN 24 340

compensator differential adjustment

lock nut

pressure adjustment

lock nut

5. Standard pressure compensator for accessory mounting, code ...MMZ

interface NG6 DIN 24 340

Version ...MMZ is designed especially for compen-

sator accessory mounting (ordering code PVAC...,

see chapter 12).

Because the accessory packages come with their

own pilot valves, this version has no integrated pilot

catridge to avoid unwanted interaction.

For more details on the different compensator

options see also the PV compensator spare parts

compensator differential

adjustment

lock nut

manual for compensator design 47, Parker bulletin

PVI-PVC-47-GB.pdf.

Note:

Checking and adjusting the compensator differen-

tial should always be done by using two pressure

sensors/gages. Measuring one pressure only

(pump outlet pressure) and assuming, that the

pilot pressure at fully unloaded pilot valve resp.

with unload proportional pilot valve is 0 bar can

lead to completely wrong adjustments.

The different pilot valves can cause even at the

nominal pilot flow (1,2 – 1,4 l/min) already signifi-

cant back pressures which add to the compensa-

tor differential.

Only if the pilot pressure chamber is completely

unloaded (e.g.: when one of the side plugs is

removed or the DCV is in stand-by mode) it can

be assumed, that the pilot pressure is zero and

pump outlet pressure is equal to the compensator

differential setting.