4

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

Axial Piston Pump

Series PV, series 47 and higher

Bulletin MSG30-3245-INST/UK

Installation manual

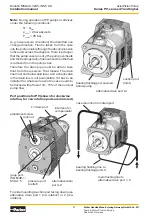

interface for

compensator

alternative drain

port L2

L1 drain port

pressure port

(outlet)

gage port,

ISO 6149-1;

M14x1.5

adjustment screw

lock nut

Port positions for PV (shown for clockwise

rotation, for ccw rotation ports are mirrored)

suction port

(inlet)

bearing flushing port, covered,

below pump

alternative drain port L3

case drain line from drain port

main flushing line to

alternative drain port 1, 2

bearing flushing line to

bearing flushing port L4

For side mounting (suction port facing down) use

alternative drain port 1 (cw rotation) or 2 (ccw

rotation).

Note:

During operation of PV pumps of all sizes

under the following conditions:

Q ~ Q

max

p

inlet

< 2 bar absolute

P

outlet

< 25 bar

(e.g. low pressure circulation) the drain flow can

change direction. Fluid is taken from the case

into the piston mainly through the decompression

orifice and across the slippers. There is a danger

that the pump case runs dry, the pump overheats

and the bearings lack of lubrication when the fluid

is removed from the pump case.

Therefore the drain pipe must be able to take

fluid from the reservoir. That means: The drain

line must end below fluid level, and a check valve

in the drain line is not permissible. If it has to be

installed for whatever reason the case needs to

be flushed with a flow of 10 – 15 % of the nominal

pump flow.