5

ELECTRICAL REQUIREMENTS

This product requires a properly-grounded 120 volt supply with a 15 amp circuit. (230 volts for

export models)

We recommend your Paragon Cotton Candy Machine be plugged directly into a dedicated outlet.

Extension cords may create a safety hazard and reduce its performance.

Be sure outlet accepts three (3) prong grounded plug. DO NOT use a three (3) prong to two (2)

prong adapter.

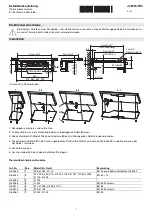

UNPACKING

Paragon carefully inspects each product during assembly and after completion to adhere to strict

quality guidelines, and packs it securely to ensure safe delivery to each of our customers. Be sure

to carefully remove all packing material and adhesive before any operation. Please examine your

product to guarantee all equipment has arrived, complete and in good condition.

If you believe that any damage may have occurred during shipment or parts may be missing,

please contact Paragon immediately for replacement.

FREQUENTLY ASKED QUESTIONS

How much will my cotton candy machine produce?

Cotton candy is unique in that production is based largely on operator skill. You may be able to

produce anywhere from 100-200 cotton candy cones per hour, based on practice.

How much spun sugar will I use?

One cone will hold approximately 1 oz. of spun cotton candy sugar – cones will likely not hold

more than that. One 18-inch plastic bag will hold 2 oz. of spun cotton candy sugar, or two

cones. Based on the amount of total cones you can realistically produce, you should then be

able to bag anywhere from 50-100 bags per hour, again depending on your skill.

How many cones will a case of floss sugar produce?

Pre-made floss sugar comes in a case of six 3-1/4 lb. containers. Each container will yield 50-

60 cones of spun cotton candy; each case will then yield 300-360 cones.

Summary of Contents for MAGIC SPIN 5

Page 2: ...2 ...