OPERATION INSTRUCTIONS

8. Push in and turn the control knob to the “HIGH”, then release

control knob. If you want a lower temperature, push in the control knob

and turn counterclockwise to the “LOW” (

Figure 5)

.

Note: If pilot fails to remain lit, all valves should be closed and a waiting

period of at least 5 minutes should pass before attempting to light.

If you experience any ignition problem please consult “Troubleshooting” on page 18.

Caution: Avoid inhaling fumes emitted from the heater’s first use. Smoke and odor from the burning

of oils used in manufacturing will appear. Both smoke and odor will dissipate after approximately 30

minutes. The heater should NOT produce thick black smoke.

Note: The burner may be noisy when initially turned on. To eliminate excessive noise from the burner,

turn the control knob to the PILOT position. Then, turn the knob to the level of heat desired.

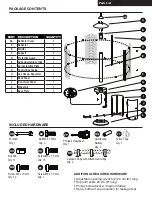

Figure 3

Figure 4

Figure 5

Igniter

Variable

control knob

Normal

Abnormal

-Repeat step 6.

through the glass tube to light the pilot (

Figure 4)

.

-As you are depressing the control knob, place long stem lighter

-Push in control knob and turn counterclockwise to “PILOT” (

Figure 3)

.

If after repeating steps 4 to 6 unit does not light, then

7.

If the pilot does not stay lit, repeat steps 4 to 6.

6.

Once the pilot is lit, continue to depress the control knob for 30 seconds.

5.

Push the igniter button until pilot flame is visible throughthe glass tube.

4.

abnormal condition.

Contrarily it is

stable and bright.

position.The flame is

tube under Low

1/3 height of glass

the height of flame is

tube under Hi position.

2/3 height of glass

the height of flameis

In Normal condition,

Note:

14

OPERATION INSTRUCTIONS

Operation Instructions

Summary of Contents for OH-M744B

Page 18: ...5016039 ...