1

Applicable signals (Video/ Component/ RGB/ PC/ HDMI input

signals)

3

2

Safety Precautions

4

2.1.

General Guidelines

4

3

Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

5

4

About lead free solder (PbF)

6

5

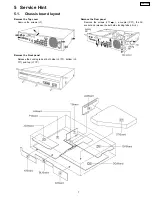

Service Hint

7

5.1.

Chassis board layout

7

5.2.

P.C.Board structure sheet of GP7P chassis

8

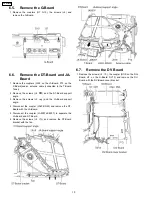

6

P.C.Board replacement method

9

6.1.

Remove the JG-Board

9

6.2.

Remove the P-Board

9

6.3.

Remove the K-Board

9

6.4.

Remove the BL-Board

9

6.5.

Remove the G-Board

10

6.6.

Remove the DT-Board and JA-Board

10

6.7.

Remove the DV Board

10

6.8.

Remove the DG-Board, T-Board and H-Board

11

7

Location of Lead Wiring

12

8

Alignment

13

8.1.

Sub contrast adjustment (NTSC)

13

8.2.

Sub contrast adjustment (HDTV)

14

8.3.

A/D converter gain adjustment (480p . 1080i)

15

9

Self-check Function

16

9.1.

Self-check of the microcomputer control system (bus line)

16

9.2.

Power LED Blinking timing chart

17

10 Serviceman Mode (Electronic Controls)

18

11 CAT (Computer Aided Test) mode

21

11.1. IIC mode

21

11.2. CD mode

22

11.3. SD mode

22

11.4. IIC mode structure (following items value is sample data.)

23

12 Circuit Board Layout

25

12.1. P-Board

25

12.2. T-Board

28

12.3. H-Board

29

12.4. DT-Board

31

12.5. JA-Board

33

12.6. DG-Board

34

12.7. DV-Board

37

12.8. BL-Board

40

12.9. G-Board

41

12.10. JG-Board

42

12.11. K-Board

44

13 Schematic Diagrams

45

13.1. Schematic Diagram Notes

45

13.2. Main Block Diagram

46

13.3. P-Board Block Diagram

47

13.4. P-Board (1 of 2) Schematic Diagram

49

13.5. P-Board (2 of 2) Schematic Diagram

50

13.6. H and T-Board Block Diagram

51

13.7. H-Board (1 of 2) and T-Board Schematic Diagram

52

13.8. H-Board (2 of 2) Schematic Diagram

53

13.9. DT and JA-Board Block Diagram

54

13.10. DT-Board (1 of 8) Schematic Diagram

56

13.11. DT-Board (2 of 8) Schematic Diagram

57

13.12. DT-Board (3 of 8) Schematic Diagram

58

13.13. DT-Board (4 of 8) Schematic Diagram

59

13.14. DT-Board (5 of 8) Schematic Diagram

60

13.15. DT-Board (6 of 8) Schematic Diagram

61

13.16. DT-Board (7 of 8) Schematic Diagram

62

13.17. DT-Board (8 of 8) Schematic Diagram

63

13.18. JA-Board Schematic Diagram

64

13.19. DG-Board Block Diagram

65

13.20. DG-Board (1 of 5) Schematic Diagram

67

13.21. DG-Board (2 of 5) Schematic Diagram

68

13.22. DG-Board (3 of 5) Schematic Diagram

69

13.23. DG-Board (4 of 5) Schematic Diagram

70

13.24. DG-Board (5 of 5) Schematic Diagram

71

13.25. DV-Board Block Diagram

72

13.26. DV-Board (1 of 5) Schematic Diagram

74

13.27. DV-Board (2 of 5) Schematic Diagram

75

13.28. DV-Board (3 of 5) Schematic Diagram

76

13.29. DV-Board (4 of 5) Schematic Diagram

77

13.30. DV-Board (5 of 5) Schematic Diagram

78

13.31. JG-Board Block Diagram

79

13.32. JG-Board (1 of 2) Schematic Diagram

80

13.33. JG-Board (2 of 2) Schematic Diagram

81

13.34. G, K and BL-Board Block Diagram

82

13.35. G, K and BL-Board Schematic Diagram

83

14 Parts Location

85

15 Mechanical Replacement Parts List

86

16 Replacement Parts List

87

Note:

Design and specifications are subject to change without notice. Weight and Dimensions shown are approximate.

CONTENTS

Page

Page

2

TU-PT700U