- 28 -

Service Manual

HV_Feedback Voltage (D08)

Procedure:

1.

Apply a NTSC all black pattern.

2.

Connect meter (+) to TPA38 and (-) to TPA20

3.

Adjust DAC D08 so that reading on meter is

5.0_V±0.2_V.

Sub-Bright Adjustment (B00)

Procedure:

1.

Set to normal picture settings.

2.

Connect meter (+) to TPA18 and (-) to TNPA19.

3.

Apply a black level pattern.

4.

Adjust DAC B00 (Sub-Brightness) so that reading

on meter is 17.0_V±1_V (7.5 IRE part is same light

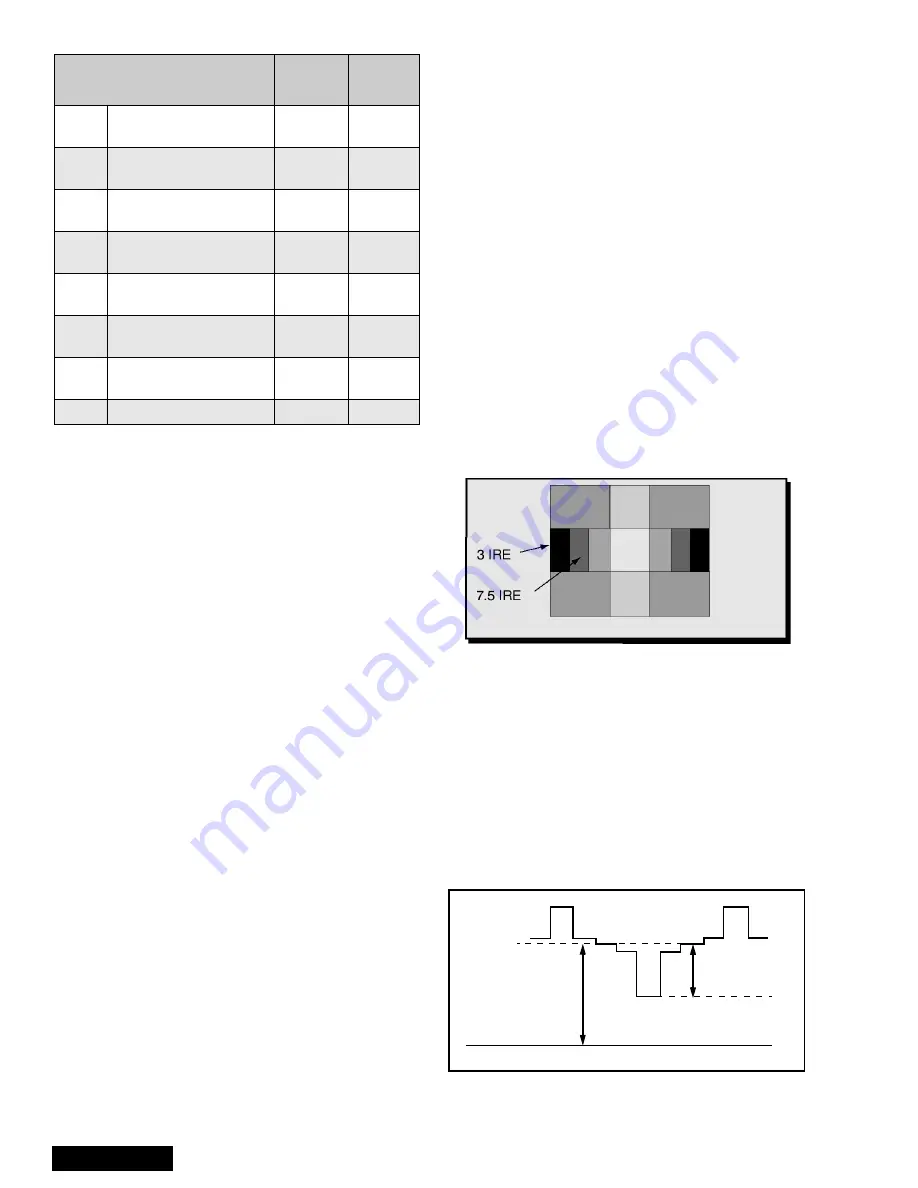

output as 3 IRE part (See Figure 56).

5.

Apply a monoscope pattern and put bright control

to max. and confirm same reading on meter.

Contrast Adjustment

Preparation:

1.

Set Auto Color and AI Picture to OFF

2.

Set the following in the user picture menu as

follows:

COLOR: min. (0)

PICTURE: max (63)

BRIGHT: center (31)

SHARPNESS: min. (0)

Set CutOff Data:

•

DAC C00 (R_CutOff) to 128.

•

DAC C01 (G_RF CutOff) to 128.

•

DAC C02 (B_CutOff) to 128.

•

DAC C06 (G_Video CutOff) to 127.

•

DAC C07 (B_Video CutOff) to 127.

•

DAC C0A (G_Video Component) to 127.

•

DAC C0B (B_Video Component) to 127.

Set Drive Data:

•

DAC C04 (

G_Drive RF) to 64.

•

DAC C05 (

B_Drive RF) to 64.

Procedure:

1.

Use 100:1 probe for measurements.

2.

Apply a Black/White Pattern (See Figure 56)

3.

Connect Scope to TPLR1 and adjust Sub-Bright

(B00) data until voltage measured is 190V

±

2V.

See Figure 57.

4.

Connect Scope to TPLG1 and adjust R-CutOff

(C00) data until voltage measured is 190V

±

2V.

(See Figure 57).

5.

Connect Scope to TPLB1 and adjust B-CutOff

(C02) data until voltage measured is 190V

±

2V.

(See Figure 57).

6.

Connect Scope to TPLR1 and adjust Sub-Contrast

(B01) data to obtain 85V±2 V between black

(7.5 IRE) and White level (See Figure 57).

V0E

User Static Data

(Vertical, Blue)

FIXED

100

V0F

User Static Data

(Horizon, Red)

FIXED

100

V10

User Static Data

(Horizon, Green)

FIXED

100

V11

User Static Data

(Horizon, Blue)

FIXED

100

V12

Test Pattern Horizontal

Phase (LOW)

FIXED

0 ~ 90

V13

Test Pattern Fine

Horizontal Phase (LOW)

FIXED

4 ~ 100

V14

Test Pattern Coarse

Horizontal Phase (LOW)

FIXED

0 ~ 0

V15

Start Line (LOW)

FIXED

0 ~ 11

Service Adjustment

Adj.

Range

Default

Level

Table 11: Service Adj. V00 ~ V15 (Continued)

Figure 56. Black/white Pattern

Figure 57. Contrast Adjustment.

GND

85V

±

2V (R)

190V

±

2V (R, G,B)

7.5 IRE

Use 100:1 Probe