– B39 –

– B38 –

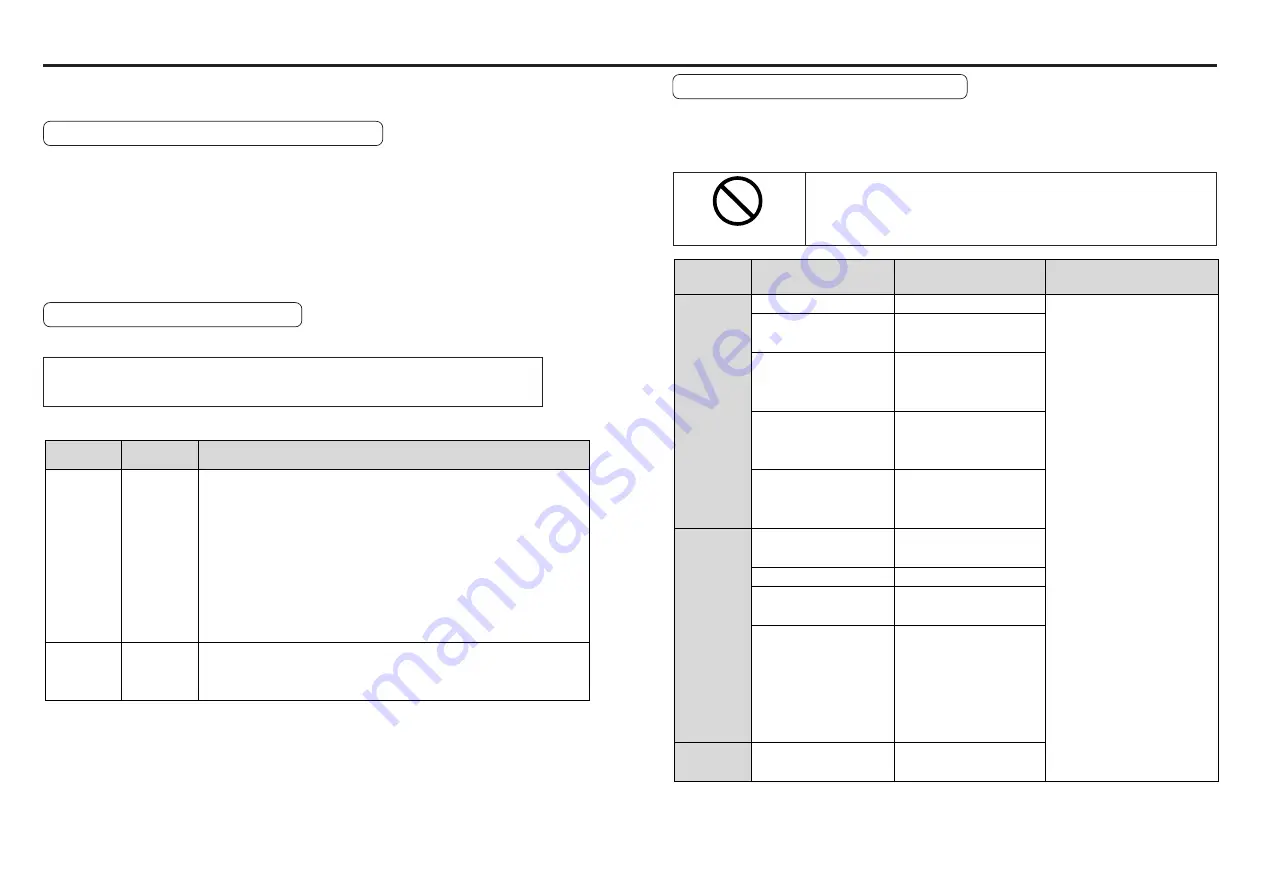

Prohibited

Disassembling for inspection and repair should

be carried out only by authorized dealers or ser-

vice company.

Daily

Annual

• Ambient temperature, humidity, speck, dust or foreign object

• Abnormal vibration and noise

• Main circuit voltage

• Odor

• Lint or other particles at air holes

• Cleanness at front portion of the driver and connecter

• Damage of the cables

• Loose connection or misalignment between the motor and

machine or equipment

• Pinching of foreign object at the load

• Loose tightening

• Trace of overheat

• Damage of the terminals

Type

Cycles

Items to be inspected

Daily

inspection

Periodical

inspection

Driver

Motor

Motor with

gear reducer

Smoothing condenser

Cooling fan

Aluminum electrolytic

capacitor (on PCB)

Rush current

preventive relay

Rush current

preventive resistor

Bearing

Oil seal

Encoder

Battery

for absolute encoder

Gear reducer

Approx. 5 years

2 to 3 years

(10,000 to 30,000 hours)

Approx. 5 years

Approx. 100,000 times

(depending on working

condition)

Approx. 20,000 times

(depending on working

condition)

3 to 5 years

(20,000 to 30,000 hours)

5000 hours

3 to 5 years

(20,000 to 30,000 hours)

Life time varies depending

on working conditions.

Refer to the instruction

manual attached to the

battery for absolute

encoder.

10,000 hours

Product

Component

Standard replacement

cycles (hour)

Note

These hours or cycles are

reference.

When you experience any

error, replacement is re-

quired even before this

standard replacement cy-

cle.

6. Maintenance and Inspections

• Routine maintenance and inspection of the driver and motor are essential for the

proper and safe operation.

Notes on Maintenance and Inspection

1) Turn on and turn off should be done by operators or inspectors themselves.

2) Internal circuit of the driver is kept charged with high voltage for a while even after

power-off. Turn off the power and allow 15 minutes or longer after LED display of the

front panel has gone off, before performing maintenance and inspection.

3) Disconnect all of the connection to the driver when performing megger test (Insulation

resistance measurement) to the driver, otherwise it could result in breakdown of the

driver.

Inspection Items and Cycles

General and normal running condition

Ambient conditions : 30˚C (annual average), load factor of 80%

or lower, operating hours of 20 hours or less per day.

Perform the daily and periodical inspection as per the items below.

<Notes>

Inspection cycle may change when the running conditions of the above change.

Guideline for Parts Replacement

Use the table below for a reference. Parts replacement cycle varies depending on the

actual operating conditions. Defective parts should be replaced or repaired when any

error have occurred.