9

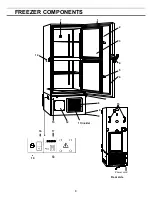

FREEZER COMPONENTS

1. Control panel (on the upper front of the outer door):

Used for temperature setting and indication

of operating status is displayed on the panel. See page 10 for details.

2.

Outer door:

To open the door, grip the handle. On closing, lock the outer door latch completely.

3. Inner door:

The operation of the inner door should be quick to minimize the temperature rise in

chamber. Lock the inner door latch completely when the inner door is closed. The inner door is

removable for cleaning or defrosting. See page 23 “Routine maintenance”.

4. Outer door latch:

Always lock the latch when the outer door is closed.

5. Inner door latch:

Always lock the inner door latch when the inner door is closed.

6. Magnetic door gasket:

This provides a tight door seal and prevents cold air leak. Keep clean.

7. Access port (rear and bottom):

This is used for leading a cable and sensor of a measuring

equipment, or nozzle of back up cooling kit to chamber.

8. Air intake vent (grille):

Do not block this vent to keep the proper cooling performance.

9. Caster:

Four casters are provided to facilitate moving of the cabinet. For the installation, adjust the

leveling foot so that the front two casters cannot contact with the floor.

10. Leveling foot:

The height of the freezer can be adjusted by this screw type foot. Keep the unit in

level at the installation.

11. Condenser filter (behind the grille):

This filter prevents the dust from accumulating on the

condenser. The dusty condenser filter may cause failure of refrigerating device. Clean the condenser

filter once a month. See page 22 “Routine maintenance” for the cleaning.

12. Space for temperature recorder:

An automatic temperature recorder (optional component) can be

attached here. See page 32“ Temperature recorder (Option)”.

13. Key lock:

Turn clockwise to 180

o

with a key and the outer door is securely locked.

14. Air intake port:

After closing the outer door, if used to open soon. See page 11

Be sure to close the cap of the air intake port after the use.

* Replace the cap when the air intake port is not used. Improper replacement may cause rise of

chamber temperature or condensation around the air intake port.

15. Fixture (on back side):

Two fixtures are provided as spacers between the cabinet and wall and also

serve as hooks to fix the unit. See page 13 “Installation”.

16. Power switch:

This is for turning ON/OFF the power to the unit. ON – “I” OFF – “

○

”

17.

Remote alarm terminal:

This is used to notice an alarm condition of the unit to remote location.

Refer to page 11 “Remote alarm terminal”.

18. Battery switch:

This is a switch for a battery for power failure alarm. Normally, turn on this switch.

Be sure to turn off this switch if the freezer is not in operating for the long period (over one month).

19. Fuse:

AC 250 V, 5 A is attached.

WARNING

Fix the shelf supports and shelves securely. Incomplete installation may cause injury or damage.

Never touch the storage items with wet hands. Touching with the wet hands may cause frostbite.

Replace the cap when the air intake port is not used. Improper replacement may cause rise of chamber

temperature or condensation around the air intake port.