50

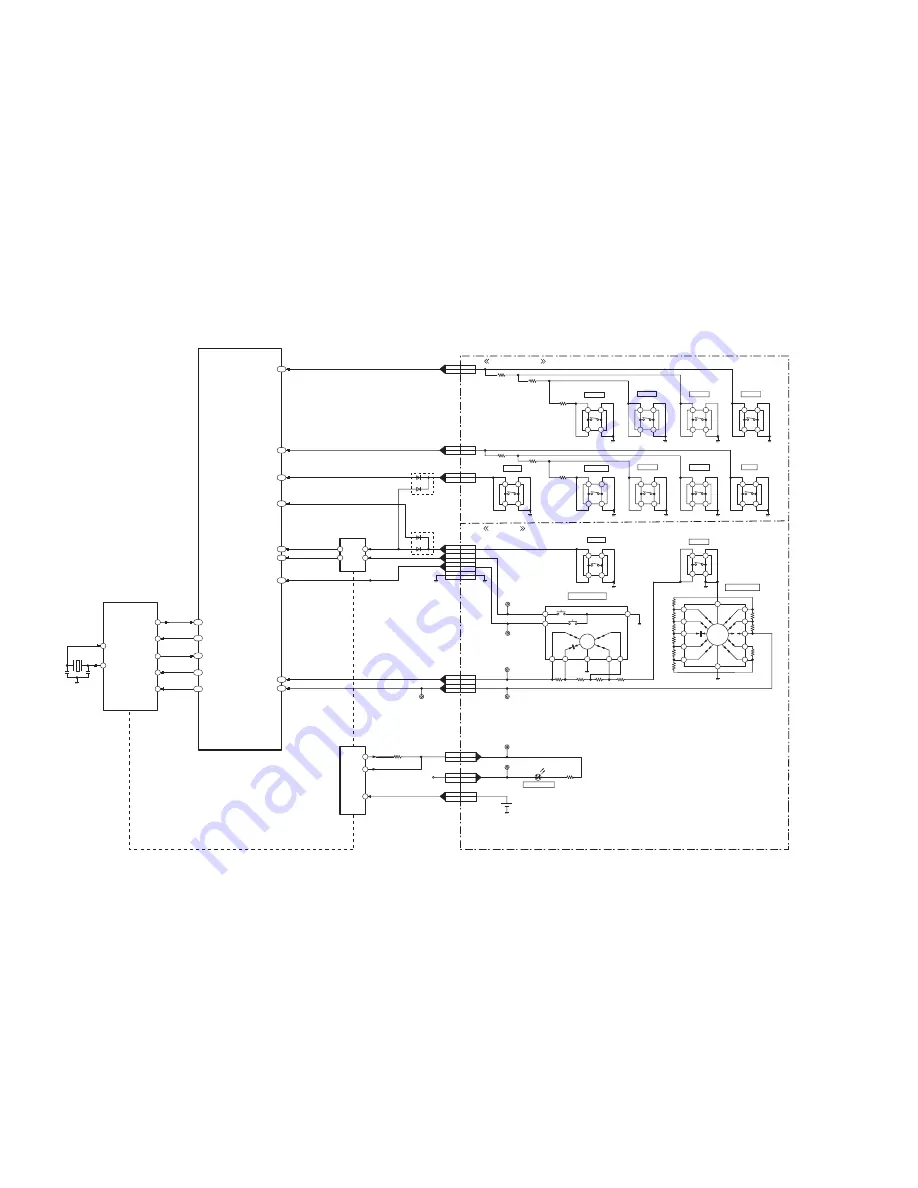

11.2. System Control Block Diagram

SHUT FULL

SYSCON CS

RSTB

POWER SW ON

DMC-TZ35/TZ36/ZS25 SYSTEM CONTROL BLOCK DIAGRAM

IC6001

(VENUS ENGINE)

SYSCON SI

67

IC9101

(SYSTEM IC)

SCCS

28

74

SO

71

SCSI

26

X9101

(32.768kHz)

SYSCON SO

SHUT HALF

87

54

IC9101

(SYSTEM IC)

OSC IN

OSC OUT

85

RESET OUT

70

SCSCLK

57

POWER SW ON H

POWER ON L

SHUTTER 0

SHUTTER HALF

IC9101

(SYSTEM IC)

SHUT HALF

C

WIDE

HI

WIDE

LO

TELE

LO

TELE

HI

83

SHUTTER 1

7

6

8

5

1

2

T W MOV

S9204

MOVIE

S9203

RIGHT

S9202

S9210

EXPOSURE

S9207

DISPLAY

S9208

DELETE

D9901

11

LEDOUT1

CROSS KEY IN

CL9907

CL9908

CL9903

CL9916

CL9917

S9904

MODE DIAL SW

S9901

ZOOM & SHUT SW

B9901

TIMER BACK UP

BATTERY

1

9

C

C

7

PW 3R6V

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

2

1

4

3

S9205

D9102

D9104

PLAY

2

1

4

3

S9902

POWER

2

1

4

3

2

1

4

3

2

1

4

3

S9206

MENU

2

1

4

3

S9903

LEFT

DOWN

8

6

5

4

3

CL9902

CL9002

REAR KEY IN

MODE DIAL

10

11

12

8

27

LEDOUT2

BATT

2

3

4

SYSCON SCK

AF ASSIST LED

S9201

2

1

4

3

UP

AF LED K

BACKUP

PP9901

18

PS9004

PS9004

5

18

PS9004

11

PP9901

11

PP9901

5

PP9901

7

PP9901

9

PP9901

10

PP9901

24,25

PP9901

8

PS9004

24,25

7

9

10

8

PP9901

12

12

PS9004

PS9004

PS9004

PS9004

PS9004

M

C2

C1

S

A

SCN

iA

P

3D

SHUTTER 1

T W MOV

MODE DIAL

TOP P.C.B.

OPERATION P.C.B.

SYS RESET

PS9201

5

5

PP9006

PS9201

1

1

PP9006

PS9201

6

6

PP9006

AC20

AB18

AA23

AB23

PLAY

POWER ON L V

U21

U22

A16

W21

W22

N24

U23

C23

C20

E22

Summary of Contents for Lumix DMC-TZ35EB

Page 21: ...21 8 Disassembly and Assembly Instructions 8 1 Disassembly Flow Chart 8 2 P C B Location ...

Page 25: ...25 8 3 4 Removal of the Operation P C B Fig D4 8 3 5 Removal of the LCD Unit Fig D5 ...

Page 26: ...26 8 3 6 Removal of the Frame Plate Unit Fig D6 8 3 7 Removal of the Lens Unit Fig D7 ...

Page 27: ...27 8 3 8 Removal of the Main P C B Fig D8 8 3 9 Removal of the Top Case Unit Fig D9 ...

Page 29: ...29 8 3 12 Removal of the Battery Case Fig D12 ...