60

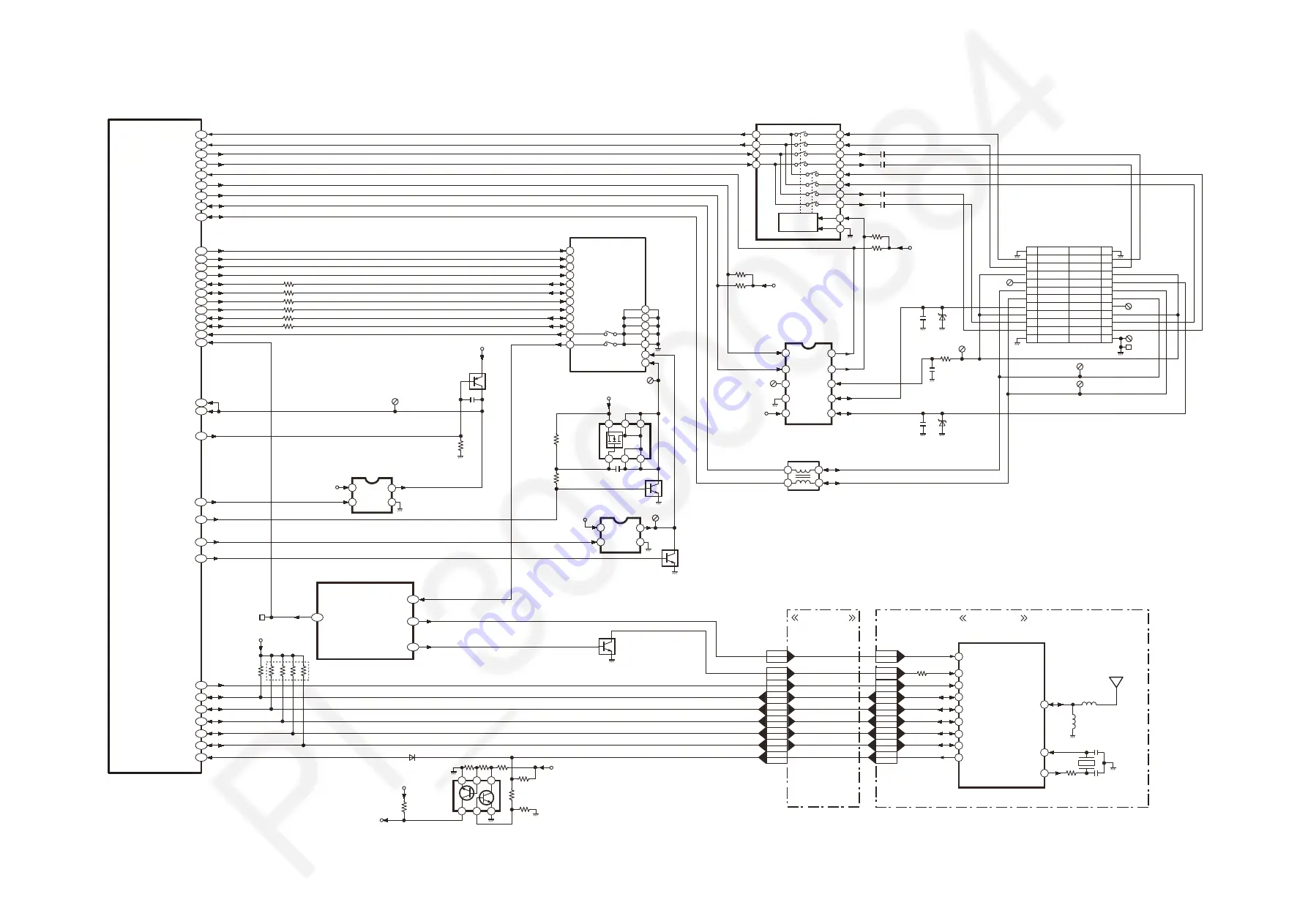

12.5. Video/Audio Process (2) Block Diagram

&'

!!

& '

$%!

& '

&! '

&! '

&! '

(

&! '

&! ) '

$

$!

&'

(

%

(

%

$

$!

$!

$!

$!(

$!

()

()

()

()

2

%

(

!B

%

(

(

!

$

(

)

!

%

%

!

(

%

$

$!

& '

&! '

&! '

&! ('

&! '

& ! '

& ! !'

& ! '

$ B

(

& ! '

& ! '

!

& ! !'

!B

(

& ! !'

%!

& #!'

(

& #!'

(2

& #!'

($

& #!'

%

& '

42

& '

%

$!(

&'

(

%

& ! (! '

$!!

2

$

& '

!B

!

!B

#B

!

#

&! '

$!

$

$$!

$$

$!(

$

%$

%

&! '

&! '

$

!

(

%

$%!

& '

&.. '

&$%!'

& '

& '

& !'

& '

& '

& ('

& '

& '

& !'

& '

& '

& ('

& '

& '

& '

& !'

& '

& '

&('

%

(

.. )))

$!!%

$!!%

(

$!!%

$!!%

$!!%

$!!%

%

$!!%

!

& '

..

2

!

!

(

%

(

!

(

!

!

!

!

!

!

!

& '

& '

& '

$!!%

"

!

& '

& '

$!!%

(

((

%

!

..

&()23'

(

(

.. )

$!!%

$

%

(

(

)

#B

#

#B

#

#B

#

(

%

B

B

2

2

$

!B

!

%

B

(

!

2

$

%

(

(

%

$

2

!

#B

#

5-:

B

5-:

#

#B

#B

#

5-:

B

5-:

#

#B

4$

& () C*+,'

$

$2

$$

()

()

$

&

'

!

2

%

(

$

()

(

%

$

& B'

& '

(

(%

& '

$

Summary of Contents for Lumix DC-GH5SE

Page 16: ...16 ...

Page 17: ...17 ...

Page 18: ...18 ...

Page 19: ...19 ...

Page 26: ...26 ...

Page 27: ...27 ...

Page 30: ...30 ...

Page 34: ...34 9 1 2 P C B Location ...

Page 37: ...37 Fig D2 Fig D3 ...

Page 38: ...38 9 1 3 2 Removal of the Main P C B Fig D4 Fig D5 ...

Page 42: ...42 Fig D16 9 1 3 10 Removal of the Mount Box Unit Fig D17 Fig D18 ...

Page 46: ...46 9 1 3 18 Removal of the Rear Plate Unit Fig D26 Fig D27 ...

Page 48: ...48 Fig D30 9 1 3 21 Removal of the Strap Unit and EXT IF P C B Fig D31 ...

Page 49: ...49 Fig D32 9 1 3 22 Removal of the Image Sensor Unit Fig D33 ...

Page 63: ...63 12 8 Hot Shoe Block Diagram 2 2 2 2 2 4 2 2 2 B 2 B 2 ...

Page 64: ...64 12 9 Flash Syncro LTC Block Diagram F 2 2 4 2 2 2 2 ...

Page 66: ...66 12 11 Power 1 Block Diagram B 9 2 2 2 4 4 4 4 4 2 B 2 2 2 2 2 B 2 2 4 42 4 9 9 ...

Page 68: ...68 12 13 Power 3 Block Diagram 9 2 2 2 2 9 4 2 2 B B B B B B H 2 2 B B B B B B H 2 2 ...

Page 69: ...69 12 14 Power 4 Block Diagram 2 F B 2 2 F 2 B 2 4 2 2 2 B 2 B 2 ...