56

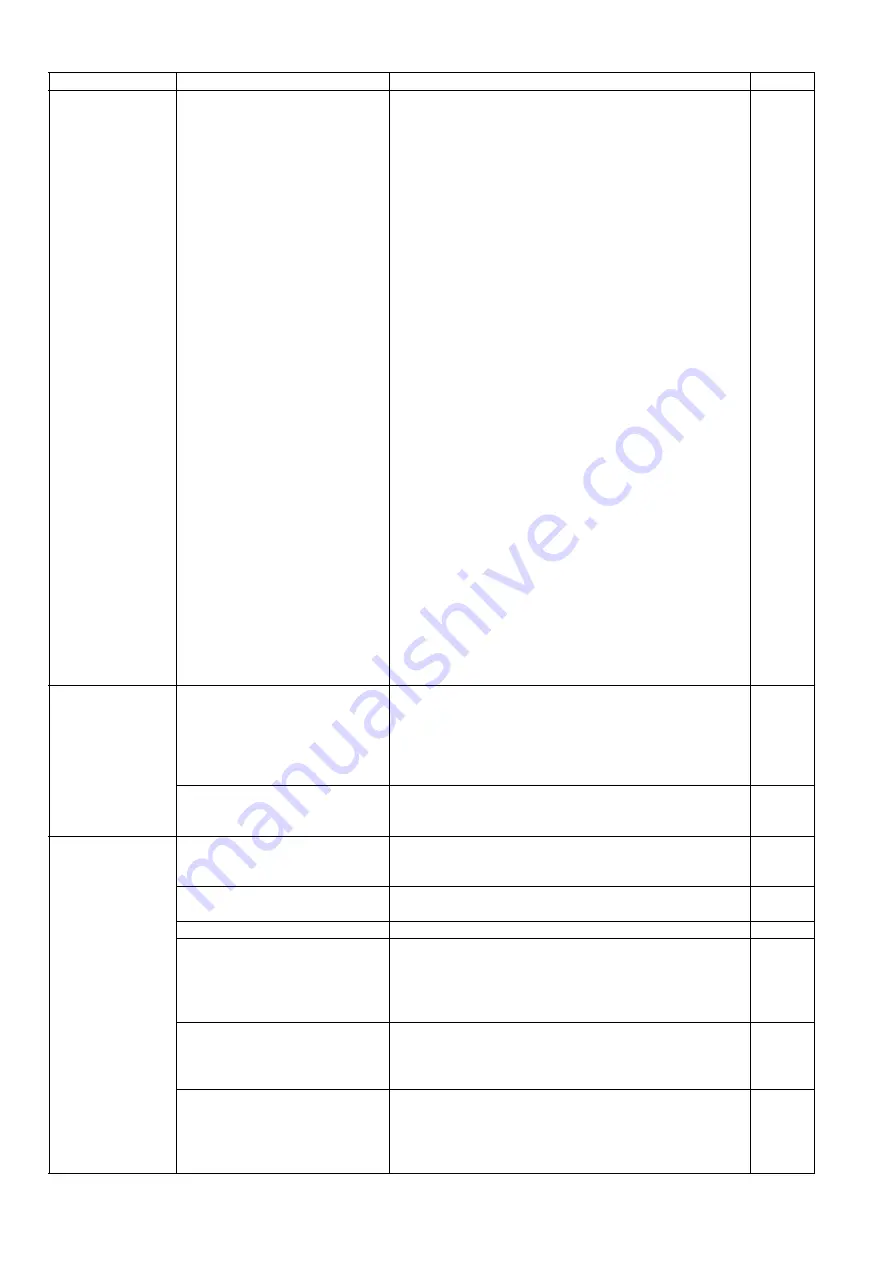

2. ON/OFF monitor circuit does not

function.

1. Check the soldering condition of the following parts

and of their surrounding circuits on the PANEL Board.

For S1057C/S1027C

(1) SW4100, R4101

(2) SW4101, R4102

(3) SW4102, R4100

(4) SW4103, R4106

(5) SW4104, R4105

(6) SW4105, R4103

(7) SW4106, R4104

For SL1066/SL1056/SL1055/SL1036/SL1035

(1) SW5000, R5017

(2) SW5001, R5018

(3) SW5002, R5019

(4) SW5003, R5020

2. Check the following connection.

For S1057C/S1027C

(1) Between CN4000 (LCD PANEL Board) and

CN3 (CONTROL Board)

(2) FFC Cable

(3) Between CN4002 (LCD PANEL Board) and

CN4100 (SW PANEL Board)

For SL1066/SL1056/SL1055/SL1036/SL1035

(1) Between CN5000 (PANEL Board) and CN3

(CONTROL Board)

(2) FFC Cable

3. Check the soldering condition of the following parts

and their surrounding circuits on the CONTROL

Board.

(1) CN3

4. Check the following signals on the PANEL Board.

For S1057C/S1027C

(1) IC4000

For SL1066/SL1056/SL1055/SL1036/SL1035

(1) IC5000

5. Replace faulty parts or boards.

Scanning position is

shifted.

1. After replacing or

re-assembling the CIS assembly

and/or mechanical parts related

to conveying documents,

re-adjustment of scanning

position has not been done.

1.

Perform the

“All Position”

and/or

“Individual Position”

in Sec.

) so that the

scanning position can be adjusted properly.

2. The CIS assembly is not

installed properly.

1. Re-assemble the CIS Assembly. (See

)

The document

skews when

scanned

1. Document Guides are not set

properly according to the size of

documents on the Feed Tray.

1. Slide and set the Document Guides according to the

document size.

2. Mixed Batch Card Guide is not

set properly.

1. Set the guide properly.

3. ADF Door is not closed tightly.

1. Close the door until it clicks into place, after opening it.

4. Rollers are dirty.

1. Clean the rollers with the roller cleaning paper.

2.

After cleaning the Paper Feed Roller and Double-feed

Prevention Roller, perform the

"Clear Counter (After

Clean Roller)"

in the service utility to clear the

cleaning roller counter. (See

(

5. Rollers are not properly installed

into their default positions when

re-assembling.

1. Check the roller attachments to the scanner (whether

a gap between roller and conveyor is secured

equally).

2. Re-attach the rollers to their default positions

6. Rollers have reached their life

expectancy.

1. After checking the configuration, replace the rollers.

2. After replacing the Paper Feed Roller and Double-feed

Prevention Roller, perform the

"Clear Counter (After

Replace Roller)"

in the service utility to clear the roller

replacement counter. (See

)

Symptom

Possible Cause

Check Point

Remarks

Summary of Contents for KV-S1027C

Page 7: ...7 ...

Page 9: ...9 3 Location of Controls and Components 3 1 Main Unit ...

Page 10: ...10 ...

Page 16: ...16 5 Section Views 5 1 Motor 5 2 Roller ...

Page 17: ...17 5 3 Board and Sensor ...

Page 31: ...31 7 3 8 Wiring of Upper Chassis ...

Page 128: ...128 14 Exploded View and Replacement Parts List ...

Page 133: ...133 14 3 Feed Tray Assembly 302 305 302 303 307 301 306 305 302 304 Feed Tray Assembly ...

Page 188: ...Index 74 8 Operating Manual Table of Contents ...

Page 255: ...PNQX6995ZA DD0914HS0 Panasonic System Networks Co Ltd 2014 ...