24

BEFORE COMMENCING OPERATION

Filling humidifying pan

Use the following procedure to fill the humidifying pan with water or to replace water in the humidifying

pan.

1.

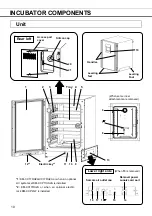

Pull out the humidifying pan toward you. (Fig. 1)

2.

Dispose of the remaining water in the humidifying pan and clean the humidifying pan with a diluted

detergent. Then rinse it thoroughly with distilled water and wipe it with alcohol for disinfection.

3.

Wipe all moisture from the bottom of the chamber.

4.

Return the humidifying pan to the chamber and

pour sterile distilled water (approx. 1.5 L, preheated

to 37

C). (Fig. 2)

Note:

●

Preheat the water to 37

C to be poured into the humidifying pan. Adding low-temperature water will

lower the temperature and humidity in the chamber.

●

Install the humidifying pan in a longitudinal direction as its shorter side is placed in the back.

●

Refill the humidifying pan with water early when the volume of water is decreased.

・

Mixing any reagent in the humidifying water may have a bad influence on the cultivation. Especially when

using the UV lamp, do not use any reagent. Because the UV light may deteriorate the reagent mixed with

the humidifying water.

5.

Set the humidifying pan with the inner side flush against the back, and close the inner door and the outer

door.

Note:

Set the humidifying pan with the inner side flush against the back. The humidity control bar in the

duct keeps at low temperatures and inner moisture is recondensed. Slide the humidifying pan down right

under the humidity control bar, otherwise the recondensed water drops will directly fall to the chamber

bottom and will pool in the chamber bottom.

Fig. 1

Fig. 2