Design, Specifications are subject to change without notice. Ask factory for technical specifications before purchase and/ or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consulation without fail.

Aluminum Electrolytic Capacitor

–

EE17

–

■

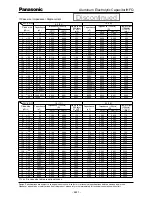

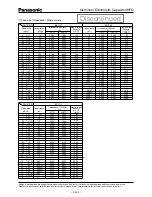

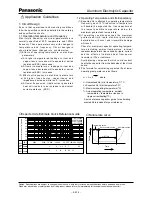

Typical failure modes and their factors

Faliure mode Faliure mechanism (internal phenomenon) Production factor Application factor

Vent operates

Increase in

internal pressure

Increase in inter-

nal temperature

Overvoltage applied

Excessive ripple current

Reverse voltage applied

Severe charging-discharging

AC voltage applied

Used for a high temperature

Used for a long period of time

Stress applied to leads

Use of Halogenated solvent

Use of adhesive

Use of coating material

Defect of oxide film

Insufficient

electrolyte

Metal particles

in capacitor

Burr(s) on foil leads

Leads improperly

connected

Mechanical stress

Leads improperly connected

Corrosion

Infiltration of Cl

Insulation breakdown of film

or electrolytic paper

Electrolyte evapora-

tion

Deterioration of

oxide film

Reduced cathode

foil capacitance

Reduced anode foil

capacitance

Capacitance

reduction

tan

d

increase

Leakage current

increase

Short circuit

Open

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

• •