Summary of Contents for HC-X910GC

Page 10: ...10 3 5 Formatting ...

Page 12: ...12 4 Specifications 4 1 For NTSC Areas ...

Page 13: ...13 ...

Page 14: ...14 ...

Page 15: ...15 ...

Page 16: ...16 ...

Page 17: ...17 4 2 For PAL Areas ...

Page 18: ...18 ...

Page 19: ...19 ...

Page 20: ...20 ...

Page 21: ...21 ...

Page 36: ...36 8 2 PCB Location ...

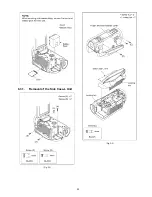

Page 39: ...39 8 3 1 Removal of the Side Case L Unit Fig D1 Fig D2 ...

Page 40: ...40 8 3 2 Removal of the SD OP P C B Cover Board Unit Fig D3 Fig D4 ...

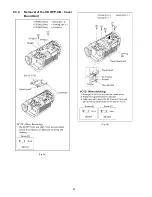

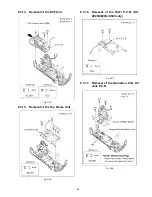

Page 42: ...42 Fig D7 8 3 5 Removal of the Front Case Unit Fig D8 ...

Page 44: ...44 Fig D11 Fig D12 ...

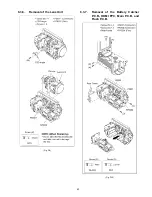

Page 46: ...46 Fig D16 Fig D17 ...

Page 52: ...52 Fig D35 8 3 23 Removal of the EVF Slide Case EVF EXT P C B Fig D36 ...

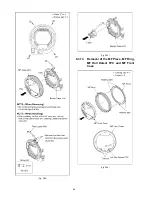

Page 53: ...53 Fig D37 8 3 24 Removal of the LCD Fig D38 8 3 25 Removal of the EVF Lens A B C Fig D39 ...

Page 56: ...56 Level Shot Adjutment Chart ...

Page 57: ...57 9 1 2 Adjustment Items Adjustment item as follows ...

Page 60: ...60 ...

Page 61: ...61 ...

Page 62: ...62 ...

Page 63: ...63 ...

Page 64: ...64 ...

Page 65: ...65 ...

Page 66: ...66 ...