22

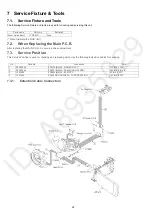

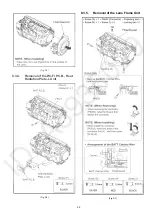

7 Service Fixture & Tools

7.1.

Service Fixture and Tools

The following Service Fixture and tools are used for checking and servicing this unit.

(* When Installing the MOS Unit )

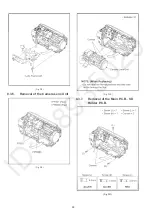

7.2.

When Replacing the Main P.C.B.

After replacing the MAIN P.C.B., be sure to achieve adjustment.

7.3.

Service Position

This Service Position is used for checking and replacing parts. Use the following Extension cables for servicing.

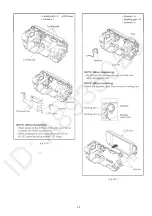

7.3.1.

Extention Cable Connection

Parts name

Parts No.

Remarks

Zoom Guide Shaft

VMS8231

2 use

No.

Parts No.

Connection

Form

1

RFKZ0354

FP6010(MAIN) - MONITOR FPC

37PIN 0.3 FFC

2

RFKZ0444

PP6001(MAIN) - PS6401(SD HOLDER)

50PIN 0.5 B to B

3

VFK1480

FP6003(MAIN) - ECM FPC

6PIN 0.5 FFC

4

VFK1440

FP6402(SD HOLDER) - TOP OPERATION

10PIN 0.5 FFC

Summary of Contents for HC-V380PP

Page 10: ...10 ...

Page 11: ...11 ...

Page 13: ...13 ...

Page 14: ...14 ...

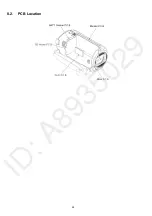

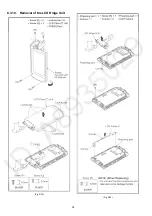

Page 24: ...24 8 2 PCB Location ...

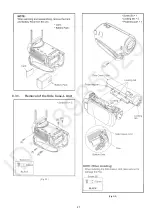

Page 27: ...27 8 3 1 Removal of the Side Case L Unit Fig D1 Fig D2 ...

Page 31: ...31 Fig D12 Fig D13 ...

Page 33: ...33 Fig D17 Fig D18 ...

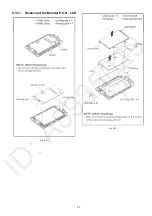

Page 34: ...34 8 3 10 Removal of the LCD Hinge Unit Fig D19 Fig D20 ...

Page 35: ...35 8 3 11 Removal of the Monitor P C B LCD Fig D21 Fig D22 ...

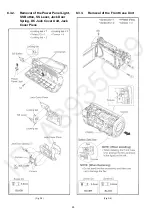

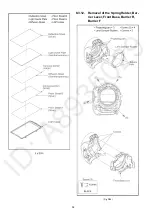

Page 38: ...38 8 3 14 Removal of the MOS Unit IR Cut Glass Fig D27 Fig D28 ...

Page 39: ...39 Fig D29 8 3 15 Removal of the 2nd Stepping Motor Fig D30 ...

Page 40: ...40 Fig D31 8 3 16 Removal of the 3rd Stepping Motor Fig D32 ...

Page 41: ...41 Fig D33 8 3 17 Removal of the Focus Stepping Motor Fig D34 ...

Page 42: ...42 Fig D35 ...

Page 45: ...45 Level Shot Adjutment Chart ...

Page 47: ...47 9 1 2 Adjustment Items Adjustment item as follows ...

Page 50: ...50 ...

Page 51: ...51 ...

Page 52: ...52 ...

Page 53: ...53 ...

Page 54: ...54 ...

Page 55: ...55 ...

Page 56: ...56 ...