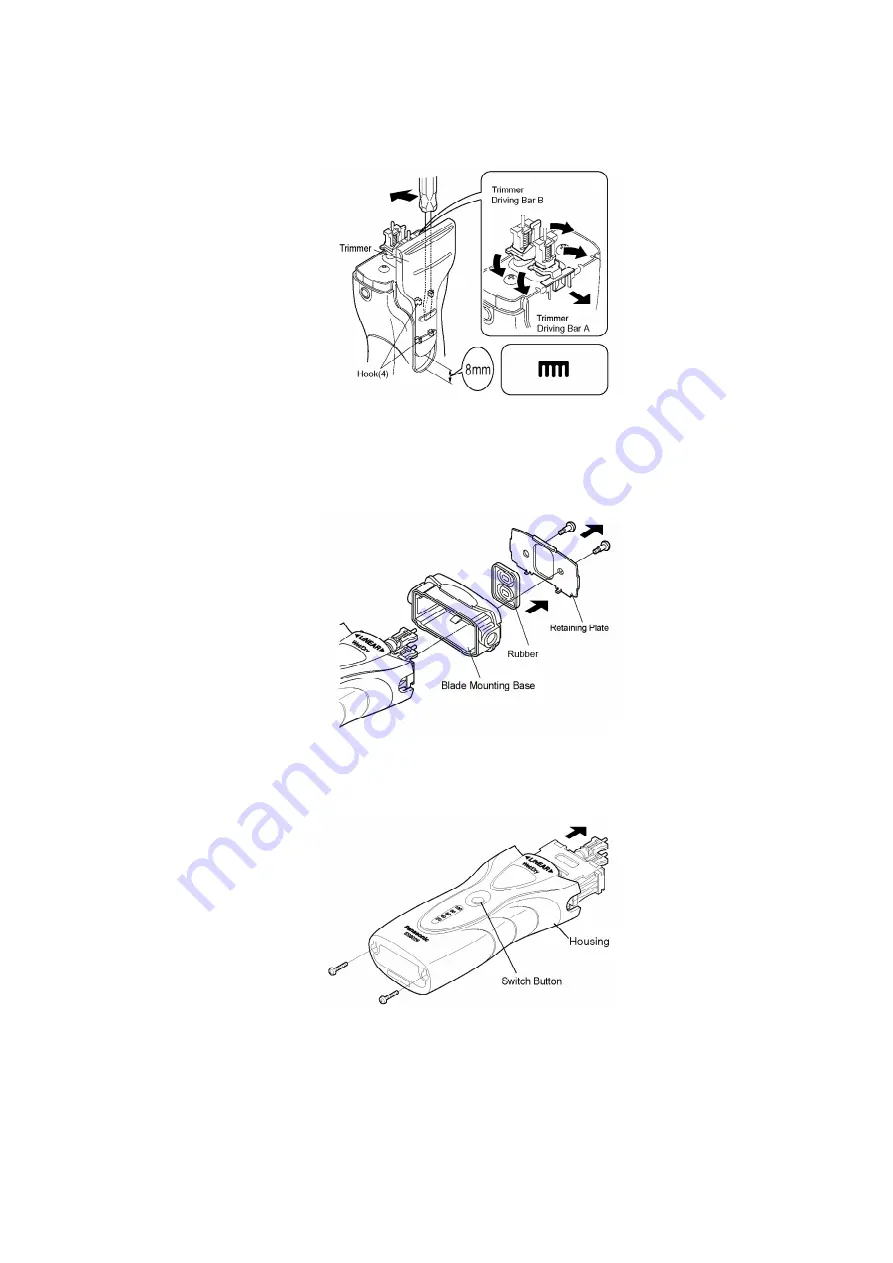

To remove the trimmer driving bars, press bar outward.

3. Loosen two screws and the retaining plate. Take out the

waterproof rubber and the blade mounting base.

4. Loosen two screws on the bottom.

5. Take out the actuator from housing. Do not push the switch

button when removing or inserting the actuator. It may cause the

3