43

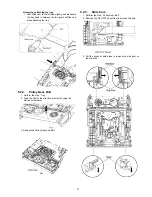

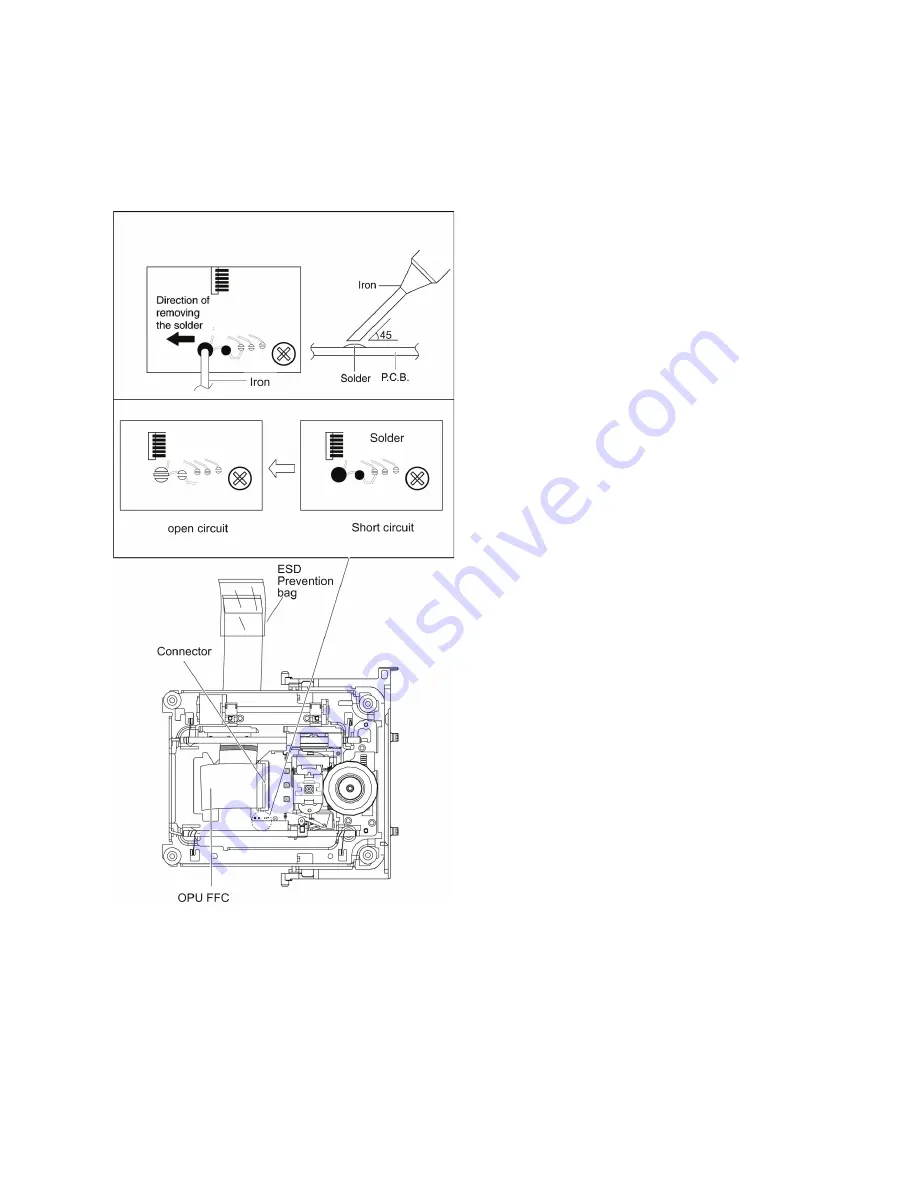

4. Insert FFC, and desolder the solder spot.

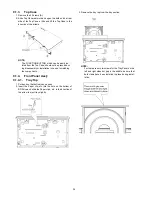

a. Use the iron head with an angle as shown in

Fig,remove the solder in the direction as shown.

b. Set the temperature of iron below 350°C.

c. When using the iron head,do not apply a force more

than 1N to the pad. Do not touch any other compo-

nents around the welding spot.

d. Welding should be applied less than 3 seconds.

Summary of Contents for DMP-BD81PU

Page 2: ...2 ...

Page 3: ...3 ...

Page 8: ...8 2 2 Precaution of Laser Diode ...

Page 18: ...18 5 Location of Controls and Components ...

Page 40: ...40 9 2 5 Grease ...

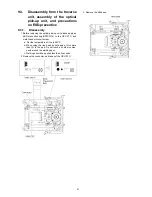

Page 44: ...44 9 3 3 How to Clean the Lens of Optical Pick UP ...

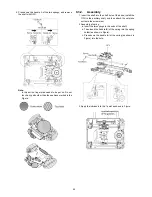

Page 45: ...45 9 4 Adjustment of BD Drive 9 4 1 Repair Flowchart ...

Page 49: ...49 10 1 2 Checking and Repairing of BD Drive and Digital P C B ...

Page 59: ...Model No DMP BD91GN 81PU 81GA 81GC 81GN 81GT BDT160GA 160GN 160GW BDT161GC PART LIST NOTICE ...

Page 60: ...Model No DMP BD91GN 81PU 81GA 81GC 81GN 81GT BDT160GA 160GN 160GW BDT161GC ABBREVIATION ...

Page 79: ...Model No DMP BD91GN 81PU 81GA 81GC 81GN 81GT BDT160GA 160GN 160GW BDT161GC Exploded View ...

Page 80: ...Model No DMP BD91GN 81PU 81GA 81GC 81GN 81GT BDT160GA 160GN 160GW BDT161GC Mechanism View ...

Page 81: ...Model No DMP BD91GN 81PU 81GA 81GC 81GN 81GT BDT160GA 160GN 160GW BDT161GC Packing View ...