8

7

6

5

When using a receiver that has been installed separately into the ceiling, use the plate

mounting.

1. Remove the face plate of the receiver by slipping a slotted screwdriver or the like into the cutout on the bottom.

2. Cut out a hole in the ceiling to match the dimensions of the ceiling installaion pattern.

3. Pass the wiring through the plate mounting and put it into the hole. (Fig. A)

4. Bend parts A and B of the plate mounting so they hold onto the ceiling fi rmly. (Fig. B)

5. Connect the receiver’s wiring (2 cores) with the wiring from the indoor unit.

(Refer to the chapter on wiring the receiver.)

When wiring receivers, be sure to double-check the terminal numbers of the indoor unit before connecting them so

there are no mistakes in the wiring. (Damage will occur if high voltage [e.g. supply voltage] is applied.)

6. Adjust the enclosed spacers so they are several millimeters thicker than the ceiling material and hold the receiver

in place temporarily with the 2 enclosed small screws.

7. Bend parts A and B back so they fi t in the opening and are in the gap between the surface of the ceiling and the

receiver; then tighten the screws. Do not use too much force when tightening the screws. Doing so may warp or

damage the case. Move the receiver by hand and check that it can move just a little. (Fig. C)

8. Attach the face plate.

Fig. A

Fig. B

Fig. C

Part A

Part B

Plate mounting

Screws (2)

(M4×1-9/16 in.)

Wiring the Receiver

Use wiring of AWG#20 – AWG#14 for fi eld supply.

Use a total wire length of no more than 1300 ft.

Polarity does not matter.

If to be used as an embedded model;

Wiring Diagram

㧝

㧞

㧝

㧞

Terminal strip for wiring the

Remote Controller of the

indoor unit

Connections

Receiver wires

(fi eld supply)

Wires from the

receiver unit

Receiver

Enclosed wire joints (2, white)

Receiver wires

(fi eld supply)

Wire joint (Enclosed)

Receiver wires

(fi eld supply)

White

Black

1. Strip the wire to be connected of its sheathing for 35/64 in.

2. Twist the two wires together and crimp the enclosed wire joint.

3. If a special crimping tool is not used, or if the connection is made using solder,

wrap the joint with insulating tape.

Test Operation

Implementing a Test Run

1. Remove the face plate of the receiver’s PCB and turn the DIP switch to RUN/On (Down

→

Up) and operate the

wireless remote controller with its Start/Stop button.

2. During a test run, all display lamps on the display will light up.

3. During a test run, it is not possible to adjust the temperature.

4. After completing a test run, be absolutely sure to return the Test Run switch to OFF (Up

→

Down) and make sure

none of the display lamps are blinking. Also, put the face plate back in place.

<Note 1> This is hard on the device, so only use this for the test run.

<Note 2> After turning on the power, the unit will not receive any commands from the remote controller for about 1

minute. This is not an error. (In fact it does receive signals, but they are cancelled.

)

<Note 3> Make sure to operate while the indoor unit is stopped.

<Note 4> The address of indoor unit is set to “ALL” at the time of the shipment.

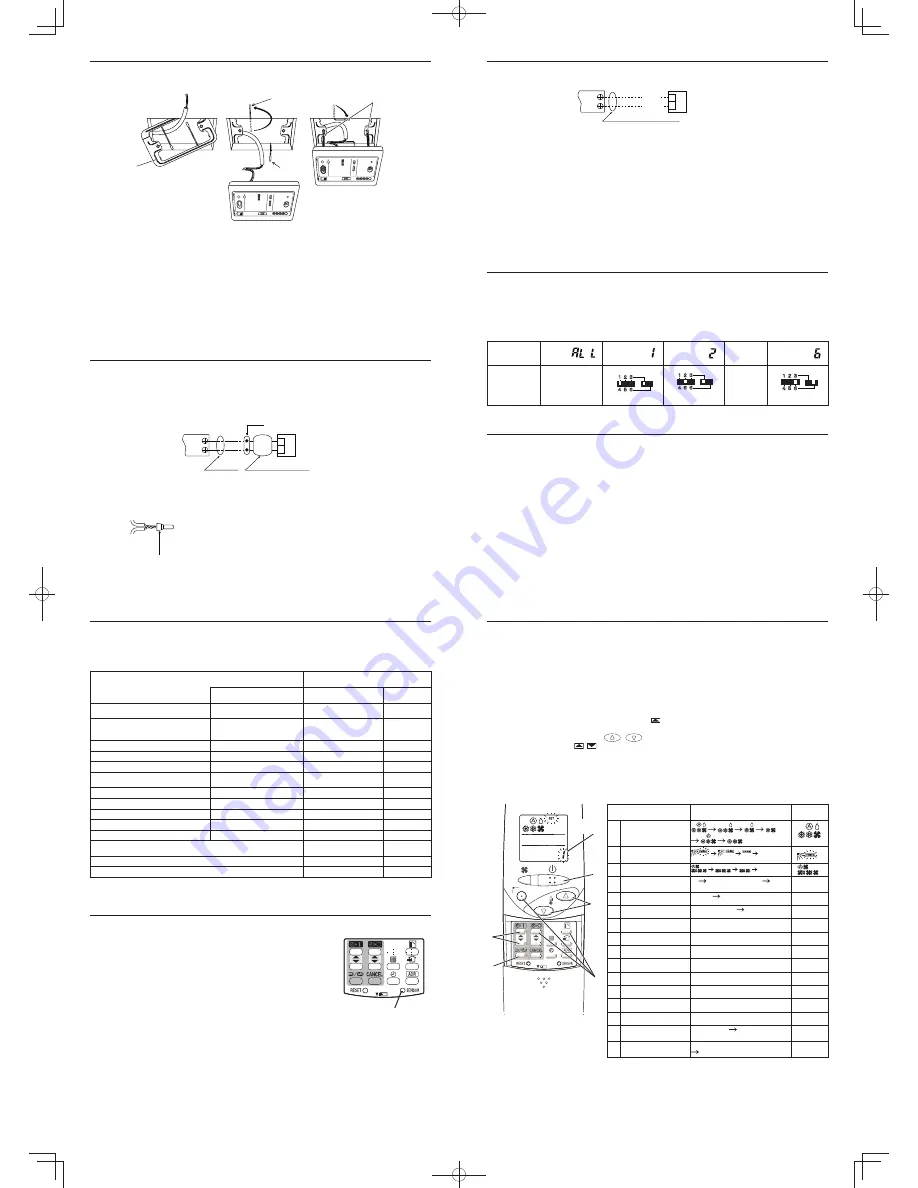

Address Display

on the Remote

Controller

・・・・・

・・・・・

Position of

the Receiver’s

Address Switch

It doesn’t matter

where the receiver’s

address switch is.

・・・・・

・・・・・

Setting Address Switches

When more than one receiver and remote controllers are installed in the same room, setting up addresses allows

them to avoid interfering with each other.

Refer to the Operating Instructions for information on how to change the addresses of the remote controllers.

Changing the address of a receiver can be done after removing the screw to the receiver’s PCB cover. Once the

change is complete, put the cover back in place; while holding the wiring with the cable clamp, tighten its screw.

㧝

㧟

㧞

㧠

㧢

㧡

㧝

㧟

㧞

㧠

㧢

㧡

㧝

㧟

㧞

㧠

㧢

㧡

㧝

㧞

㧝

㧞

If it is to be used as an exposed model:

Wiring Diagram

<Note 1> When wiring remote controllers, be sure to double-check the terminal numbers of the indoor unit

connecting them so there are no mistakes in the wiring. (Damage will occur if high voltage [e.g. supply

voltage] is applied.)

<Note 2> If the wiring to the operation panel is bundled together with other wiring, such as the incoming line from

the power source, it can cause a malfunction, so avoid doing so.

<Note 3> If something causes the unit’s power source to make noise, it will be necessary to resolve the problem,

such as by installing a noise fi lter.

Receiver

Terminal strip for wiring

the Remote Controller of

the indoor unit

Remote Control Wiring

(Sold Separately)

Use remote control wiring (sold separately) for wiring a separately installed receiver.

1. For instructions on how to install a remote control wiring (sold separately), refer to the chapter on Using as an

Embedded Model in Installing Separate Receivers.

2. If a remote control wiring (sold separately) is to be used, refer to the Mounting Instructions attached to the remote

control wiring.

White

Black

The Self-Diagnosis Function Display and What is Detected

Alarm Display in the table below indicates the content of alarms that are displayed when a wired remote

controller is connected. For information on how to deal with the alarms, refer to the Mounting Instructions for

the indoor unit or to Test Run or servicing materials.

●

: Off /

○

: On /

◎

: Blinking (0.5 sec. intervals)

Common to All Models

The indoor unit and the wireless remote controller are equipped with

indoor temperature sensors. The sensing of indoor temperature works

via one of them.

When the unit is shipped, it is set to the indoor unit, but to switch to

the remote controller, press the sensor button (diagram at right) inside

the remote controller’s cover and then check to make sure that Main

Sensor on the LCD screen goes off.

<Note>

Even when the sensor switch has been set to the remote

controller, if the unit does not receive any room temperature

data from the remote controller for ten minutes, it

automatically switches back to the indoor unit sensor, so be

sure to install the remote controller facing the receiver.

Error Detected

WL Remote Control LED Display

Alarm Display

Run

Timer

Standby

Blinking

Communication error in the remote control

circuit

E01–E03, E08–E14, E17, E18

◎

●

●

Communication error either in the in/

outdoor operation line or the sub-bus of

the outdoor unit

E04–E07, E15, E16, E19–E31

●

●

◎

Operation of indoor protection device

P01, P09–P14

●

◎

◎

Alternately

Operation of outdoor protection device

P02–P08, P15–P31

◎

●

◎

Alternately

Error in the indoor thermistor

F01–F03, F10–F11

◎

◎

●

Alternately

Error in the outdoor thermistor

F04–F09, F12–F28

◎

◎

○

Alternately

Error in the indoor EEPROM

F29

◎

◎

●

Simultaneously

Error in the outdoor EEPROM

F30, F31

◎

◎

○

Simultaneously

Error related to the compressor

H01–H31

●

◎

●

Error in indoor settings

L01–L03, L05–L09

◎

●

◎

Simultaneously

Error in outdoor settings

L04, L10–L31

◎

○

◎

Simultaneously

Inconsistency in Air/Heat (Including an auto-temp setting for a model without

auto-temp settings)

○

◎

◎

Alternately

Oil Alarm (Same as operation of outdoor protection device)

◎

●

◎

Alternately

Test Run

◎

◎

◎

Simultaneously

Room Temperature Sensor Settings

Sensor Button

Setting Up Remote Control Functions

The functions of the wireless remote can be set on site.

(These settings are saved in nonvolatile memory in the remote controller, so even when its batteries are

changed, the settings do not revert to the defaults.)

<Note> The operation of the air conditioner can be impacted, depending on the settings made, so only service

personnel should make the settings.

Furthermore, making changes to these settings may cause actual operation to deviate from what is

printed in the Operating Instructions, so be sure to explain this to the customer fully.

Making Settings (Do with unit stopped.)

1. Holding down the Swing/Wind Dir OFF Timer

+ Mode Select buttons at the same time for 4 or more

seconds makes the display switch to the setting screen. (See Diagram Below.)

2. Use the Temperature setting buttons,

/

, to select the number of the item to be set.

3. Use the ON Timer buttons,

/

, to change settings.

4. The settings are saved with the Once/Every Day button. When this is done, the settings display of the LCD

changes from blinking to light.

5. If other settings are to be changed as well, repeat steps 2 to 4.

6. When all settings have been made, press the Start/Stop button.

Example: Operation mode setting screen

Note 1

While the unit is in the swinging mode (Swing/Wind Direction), the fl ap cannot be stopped in a desired

position.

Note 2

When Setting OFF is selected, “°C” is displayed on the LCD screen.

Note 3

You can toggle between ON and OFF by pressing Ventilation for 4 seconds or more.

Note 4

If the Heater Max ON/OFF setting is not changed to EP (ON), the setting change will not be refl ected.

Note 5

This is the number of addresses that can be set in the address change mode. Do not set it to 07 or above.

Item Number & Setting Item

Setting Content

Setting when

Shipped

1

Operation Mode

2

Flap Display

3

Select Fan Speed

4

Display of Set

Temperature

°F

Setting Off (Note 2)

°C

°F

5

Time Display

AM/PM

24 Hour (No Display)

AM/PM

6

Ventilation Fan ON/OFF Off (No Display)

On

OFF

(Note 3)

7

Cool temp Max

41 – 95°F

86°F

8

Cool temp Min

41 – 95°F

64°F

9

Heat temp Max

41 – 95°F

78°F

(Note 4)

10

Heat temp Min

41 – 95°F

60°F

11

Dry temp Max

41 – 95°F

86°F

12

Dry temp Min

41 – 95°F

64°F

13

Auto temp Max

41 – 95°F

80°F

14

Auto temp Min

41 – 95°F

62°F

16

Address Setting Max

Value

00 (ALL only)

01 – 31

06 (Note 5)

17

Heat temp Max ON/OFF JP (Heater Max Temp Change Off)

EP (On)

JP

1

4

3

2

6

(Note 1)

(No Display)

(No Display)

Item

Number

Printed in Japan

85464369519011

Panasonic̲INST MANUAL̲CZ-RWSC1U.indd 2

Panasonic̲INST MANUAL̲CZ-RWSC1U.indd 2

2012/01/25 13:38:08

2012/01/25 13:38:08