PS-A (ADP5)

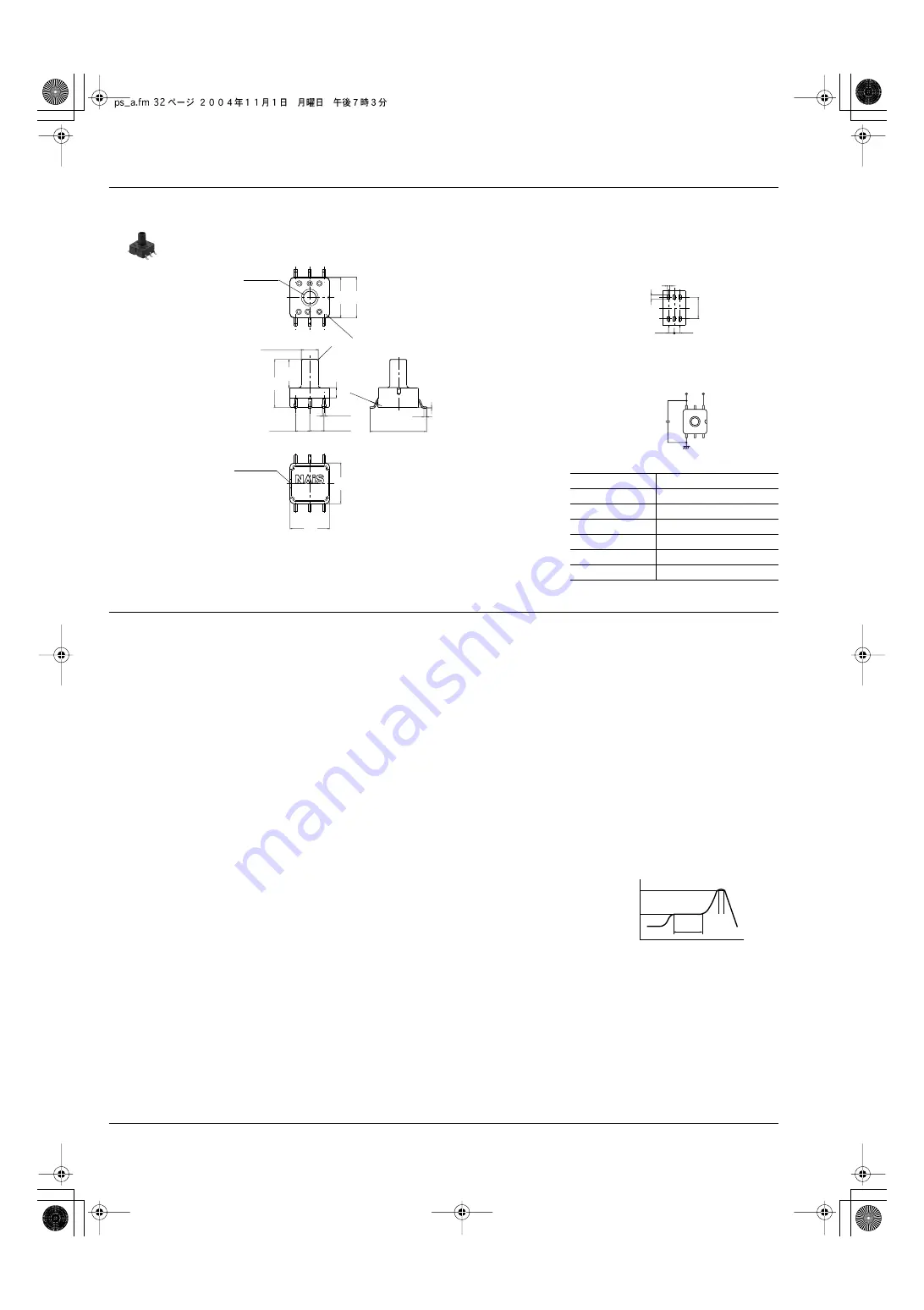

4. SMD terminal (Pressure inlet hole: 5mm) ADP52*1

NC

GND NC

Vcc NC Vout

Vcc NC Vout

10.0

±

0.3

.394

±

.012

0.5

.020

JAPAN

.098

±

.010

2.5

±

0.25

.098

±

.010

2.5

±

0.25

0.25

±

0.1

.010

±

.004

NC

GND

NC

T

Y

R

W

Q

E

Atmospheric

pressure

inlet hole

Pressure

inlet hole

2.2 dia.

.087 dia.

R0.2

R

.0

08

3.0

dia.

4-R0.7

4-R.028

0.5

±

0.1

.020

±

.004

0

–0.1

.118

dia.

0

–.004

7.2

.283

7.0

.276

1.8

.071

7.2

.283

7.0

.276

0.15

±

0.1

.006

±

.004

8.5

.335

5.0

.197

Recommended PC board pattern

(TOP VIEW 2:1)

Terminal connection diagram

Terminal No.

Name

1

Vcc (Power supply [+])

2

NC (No connection)

3

Vout (Output)

4

NC (No connection)

5

NC (No connection)

6

GND (Ground)

2.5

.098

2.5

.098

1.1

.043

9.5

.374

1.9

.075

Vcc (5V DC)

Vout

C (0.1

µ

F)

GND

mm

inch

General tolerance: ±0.3

±.012

NOTES

1. Mounting

Use lands on the printed-circuit boards to

which the sensor can be securely fixed.

2. Soldering

Due to its small size, the thermal capacity

of the pressure sensor DIP type is low.

Therefore, take steps to minimize the

effects of external heat.

Damage and changes to characteristics

may occur due to heat deformation.

Use a non-corrosive resin type of flux.

Since the pressure sensor DIP type is

exposed to the atmosphere, do not allow

flux to enter inside.

1) Manual soldering

• Set the soldering tip from 260 to 300°C

(30W), and solder for no more than 5

seconds.

• Please note that output may change if

the pressure is applied on the terminals

when the soldering.

• Thoroughly clean the soldering iron.

2) DIP soldering (DIP terminal type)

• Please keep the DIP solder bath

temperature no higher than 260°C. When

soldering, heat should be applied no

longer than five seconds.

• When mounting onto a PCB of low

thermal capacity, please avoid DIP

soldering as this may cause heat

deformity.

3) Reflow soldering (SMD terminal type)

• The recommended reflow temperature

profile conditions are given below.

• We recommend the screen solder

printing method as the method for cream

solder printing.

• Please refer to the recommended PCB

specification diagram for the PCB foot

pattern.

• Self alignment may not always work as

expected; therefore, please carefully

adjust the position of the terminals and

pattern.

• The profile temperature is the value

measured on the PCB near the terminals.

• When doing reflow soldering on the back

of the PC board after performing sensor

reflow, please fix the sensor with adhesive

and so on.

4) Solder reworking

• Finish reworking in one operation.

• For reworking of the solder bridge, use a

soldering iron with a flat tip. Please do not

add more flux when reworking.

• Please use a soldering iron that is below

the temperature given in the

specifications in order to maintain the

correct temperature at the tip of the

soldering iron.

5) Too much force on the terminals will

cause deformation and loss in

effectiveness of the solder. Therefore,

please avoid dropping and careless

handling of the product.

6) Please control warping of the PCB

within 0.05 mm of the sensor width.

7) When cut folding the PCB after

mounting the sensor, take measures to

prevent stress to the soldered parts.

8) The sensor terminals are designed to

be exposed, so contact of the terminals

with metal shards and the like will cause

output errors. Therefore, please be

careful and prevent things such as metal

shards and hands from contacting the

terminals.

9) To prevent degradation of the PCB

insulation after soldering, please be

careful not to get chemicals on the sensor

when coating.

10) Please consult us regarding the use of

lead-free solder.

3. Connections

1) Please perform connections correctly

in accordance with the terminal

connection diagram. In particular, be

careful not to reverse wire the power

supply as this will cause damage or

degrade to the product.

2) Do not connect terminals that are not

used. This can cause malfunction of the

sensor.

With in

60 sec.

Preheating

Time

Temperature

Peak temperature

150

°

C

302

°

F

230

°

C

446

°

F

(230

°

C

446

°

F

max.

and 10 sec. max.)