system component breakdown and can indicate potential

failure. Discard both the element and its O-rings in

accordance with local Health and Safety Procedures. The

filter element is NOT CLEANABLE. Any attempt to clean

the filter can cause degradation of the filter medium and

allow contaminated fluid to pass through the filter.

7.4 Inspect filter cover assembly (5) and bypass valves

for possible damage or malfunction. Replace filter

cover assembly if damage is observed. Remove any

accumulated dirt from the filter tube interior and cover

assembly being careful to prevent contaminant from

entering the outlet and flowing downstream. DO NOT

run the system without a filter element (8) installed.

Check the O-rings (6) on the cover assembly (5) and

centre post (3) are not damaged. Use the correct

replacement filter element (8) part number called for on

assembly nameplate.

7.5 Lubricate element O-ring seals with clean system fluid

and push filter element (8) straight over the housing

centre post. Ensure the cover assembly (5) and centre

post (3) threads are clean and dry. Lightly lubricate the

centre post threads, O-ring seal and cover assembly

seals with clean system fluid. HAND TIGHTEN cover

handle until cover assembly and tube are in contact.

O-ring sealing is not improved by over tightening.

7.6 Open housing vent plug (10). Open commuter valve

(16) (three full turns max). Slowly open commuter valve

to equalise the pressure between the two sides of the

housing. Close vent plug when bubble free fluid issues

from it. Close commuter valve and check for leaks. Filter

housing is now ready for changeover when required.

Close commuter valve (16).

NOTE: For UR649, UR669 and UR689 units, the above applies

to each housing having elements replaced.

7.8 After element change ENSURE VISUAL DIFFERENTIAL

PRESSURE WARNING DEVICE IS RESET BY

PUSHING IN THE BUTTON; electrical devices are

reset automatically. When system reaches normal

operating temperature, check that electrical switch has

not actuated and/or that visual warning button remains

depressed. If visual indicator rises due to a cold start

condition, reset again as per Section 6.

8

Fluid sampling

Optimum sampling to verify fluid condition can be achieved

by the use of sampling adaptors installed in place of or in

combination with the differential pressure device. This provides

up and downstream 1/4-inch BSP parallel thread ports to be

used for sampling. For more information consult Pall or your

local Pall distributor. Pall offers a fluid contamination analysis

service - consult the Pall sales office.

4

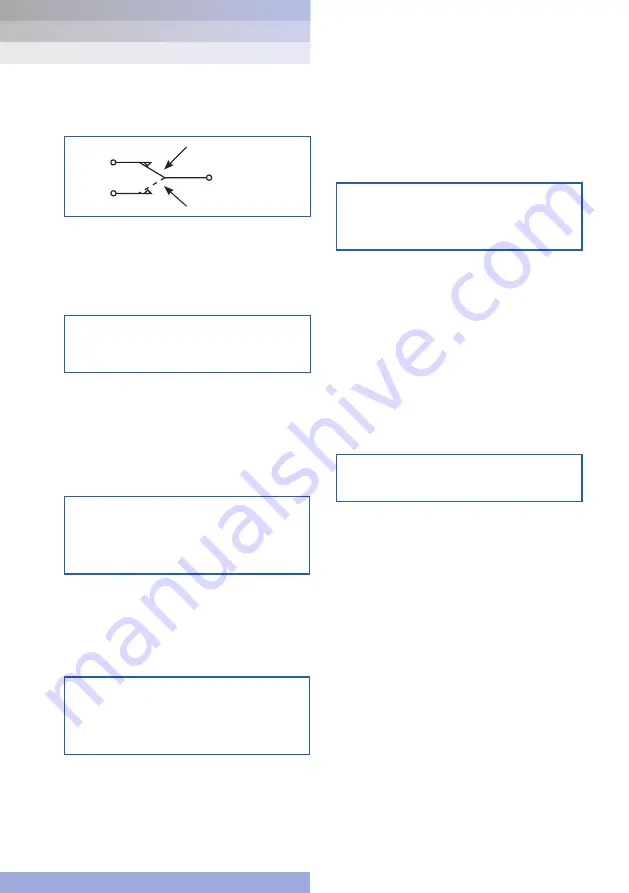

Figure 1

- Switch Circuit Diagram

C or black or

tag 2

A or white

or tag 1

B or red

or tag 3

LOW DIFFERENTIAL PRESSURE

HIGH DIFFERENTIAL PRESSURE

RETURN LINE FILTERS

s e r v i c e

i n s t r u c t i o n s

Athalon

®

UR629/649/669/689 Series

WARNING:

FAILURE TO REPLACE DAMAGED PARTS IN THE

FILTER ASSEMBLY CAN CAUSE COMPONENTS IN

THE HYDRAULIC SYSTEM TO FAIL OR DEGRADE IN

THEIR PERFORMANCE.

WARNING:

DO NOT USE PIPE WRENCH, HAMMER OR ANY

SIMILAR TOOL TO TIGHTEN COVER.

7

Filter element servicing

During servicing, the external surfaces of the filter assembly

must be cleaned to remove any dust deposits.

Servicing must be conducted using suitable tools that do not

present a hazard.

Servicing must not be carried out when a potentially explosive

atmosphere is present.

Refer to Service Parts List (Section 10) for item numbers for

applicable replacement element series. Remove and replace

element as follows:

7.1 Open commuter valve (16) (three full turns max). Crack

open off-line vent plug. Slowly open commuter valve to

equalise pressure in the two sides of the housing. Close

vent plug when bubble-free fluid issues from it. Close

commuter valve (16).

NOTE: Change-over valve handle indicates the filter housing on

stream.

7.2 The off-line housing, now isolated from the system by the

change-over valve, is depressurised by slowly venting

through the vent plug (10). Open drain plug (11) and drain

fluid into a suitable container. Discard fluid in accordance

with local Health and Safety regulations. Close drain plug

(11) and torque tighten to 12 ft/lbor 16 Nm.

NOTE: During element replacement some small internal

leakage may be noted from the on-line filter housing.

7.3 Manually unscrew cover handle and remove filter cover

assembly (5) from tube (2). Remove element (8), if already

fitted, and carefully inspect the surface for significant

visible contamination. Normally no dirt should show but

visible dirt or particles from the filter tube (2) interior

and filter cover assembly (5) can be an early warning of

CAUTION:

Filter elements should be replaced upon indication or

at specified intervals, six months maximum. Failure to

change the element will cause the filter to go on bypass.

WARNING:

FAILURE TO CLOSE THE COMMUTER VALVE AND

TO DEPRESSURISE THE FILTER HOUSING BEFORE

SERVICING THE FILTER ELEMENT COULD RESULT

IN EXPLOSIVE LOSS OF FLUID, DAMAGE TO

EQUIPMENT AND POSSIBLE PERSONNEL INJURY.

WARNING:

DO NOT ATTEMPT TO CLEAN OR RE-USE THE

ELEMENT.

ONLY USE GENUINE PALL REPLACEMENT FILTER

ELEMENTS. USE OF SUBSTITUTE ELEMENTS MAY

INVALIDATE PRODUCT WARRANTY.