D U P L E X F I L T E R A S S E M B L Y

s e r v i c e

i n s t r u c t i o n s

ENGLISH

(f)

Install O-rings (13, 20) into grooves in head.

(g) Clean all threads before applying Loctite 243 medium

strength to Socket Head Cap Screws (6) and hex bolt

(6.1), install and torque to 50-55 LB-FT.

(i)

Install Filter Element (10) per Section 7.

8.6 Lubricate o-rings and install bleed and drain plugs (5

and 8) and torque to 10-14 LB-FT.

8.7 Commission filter assembly per Section 4.5.

9

Check Valve Servicing

NOTE: Service Check Valve at the same time

as Ball Valve service.

9.1 Completely shut down system and depressurize system

by opening bleed plugs (5) and remove drain plugs (8)

after depresurizing.

9.2 With the ball valve handle shaft facing the operator,

remove the right hand Head Assembly.

(a) Remove Filter Element (10) per section 7.

(b) Remove 4 Socket Head Cap Screws (6) and loosen 1

hex head bolt. Remove head (1).

9.3 Remove Check Valve assembly by pulling straight

out. (11).

9.4 Restrain one of the valve seats and unscrew the

opposite end (see Fig. 8). (DO NOT DAMAGE SEAL

AREA AND DO NOT HOLD ONTO THE SHAFT).

9.5 Remove the poppets.

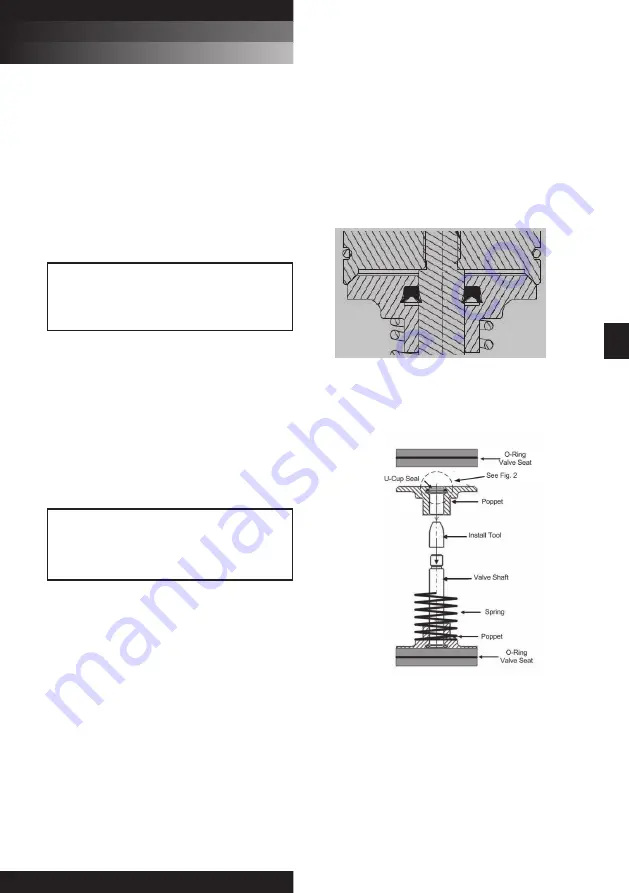

NOTE: Lubricate all seals before installation. The open end of

the U-cup seal must point toward the center of the Check

Valve Assembly. (see Fig. 2)

9.6 Replace O-rings and U-cup seals. Use appropriate kit

per type of seal. See Check Valve Seal Kit list.

(Section 13)

NOTE: Poppets and seats are matched sets. Do not

interchange seats and poppets. See Fig. 3 for proper part

configuration.

9.7 Assemble (per Figure 3.)

NOTE: Use seal installation tool to install new seals and

poppets onto the valve shaft. Failure to use this tool will

damage the U-cup seals.

9.8 Clean all threads before applying removable Loctite 243

to shaft threads and attach removed seat.

9.9 Install Check Valve Assy. (11).

9.10 Install head. Clean all threads before applting Loctite

243 medium strength to Socket Head Cap Screws (6)

and hex bolt (6.1), install and torque to 50-55 LB-FT.

9.11 Install Filter Element (10) per Section 7.

9.12 Lubricate o-rings and install bleed and drain plugs (5

and 8) and torque to 10-14 LB-FT.

9.13 Commission filter assembly per Section 4.7.

5

UR229

UR229 Series

WARNING:

FAILURE TO DEPRESSURISE THE SYSTEM BEFORE

SERVICING UNIT COULD RESULT IN EXPLOSIVE

LOSS OF FLUID. DAMAGE TO EQUIPMENT AND

POSSIBLE PERSONAL INJURY.

WARNING:

THIS ASSEMBLY IS SPRING LOADED. ENSURE

ASSEMBLY IS PROPERLY RESTRAINED DURING

DISASSEMBLY TO PREVENT POTENTIAL FOR

DAMAGE TO PARTS OR POSSIBLE PERSONAL INJURY.

U-Cup Orientation

Figure 2

Check Valve Configuration

Figure 3