11

UNPLUG

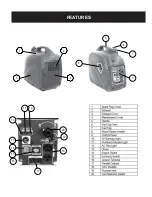

Connecting Generator to an Electrical System

• If connecting generator to a building’s electrical system for standby

power,

The power

from the generator must be isolated from the circuit breaker or

alternative power source. The connection must comply with all electrical

codes and applicable laws.

Never directly connect

generator to a household

power source.

Adding Fuel

• Place generator on a clean and level surface in an area that is well ventilated.

• Remove fuel cap.

• Insert a funnel into the fuel tank and carefully pour petrol into the tank until fuel level

reaches about 1½ inches below the top of the neck. Be careful not to overfill the tank

to provide space for fuel expansion.

• Replace fuel cap and secure tightly.

Do not smoke when adding fuel.

Do not overfill the fuel tank.

Provide space for fuel

expansion.

Turn cap counter

clockwise to remove.

ASSEMBLY

• Never handle the generator, electronic devices or any cord while standing in water, while barefoot, or when hands

or feet are wet.

• Always keep the generator dry. Never operate generator in rain or under wet conditions.

• Use a ground fault circuit interrupter (GFCI) in a damp or highly conductive area, such as metal decking or steel

work.

• Never plug electronic devices into generator having frayed, worn, or bare wires. Never touch bare wires

• •

generator at all times.

• If using the generator for backup power, notify the utility company.

•

install a transfer switch. Failure to isolate the generator from the power utility could result in serious injury or

death to electric utility workers.

This generator produces a very high voltage which could result in burn or

electrocution causing serious injury or death.

WARNING!

OFF

ON