Last Update: 30/01/17

2

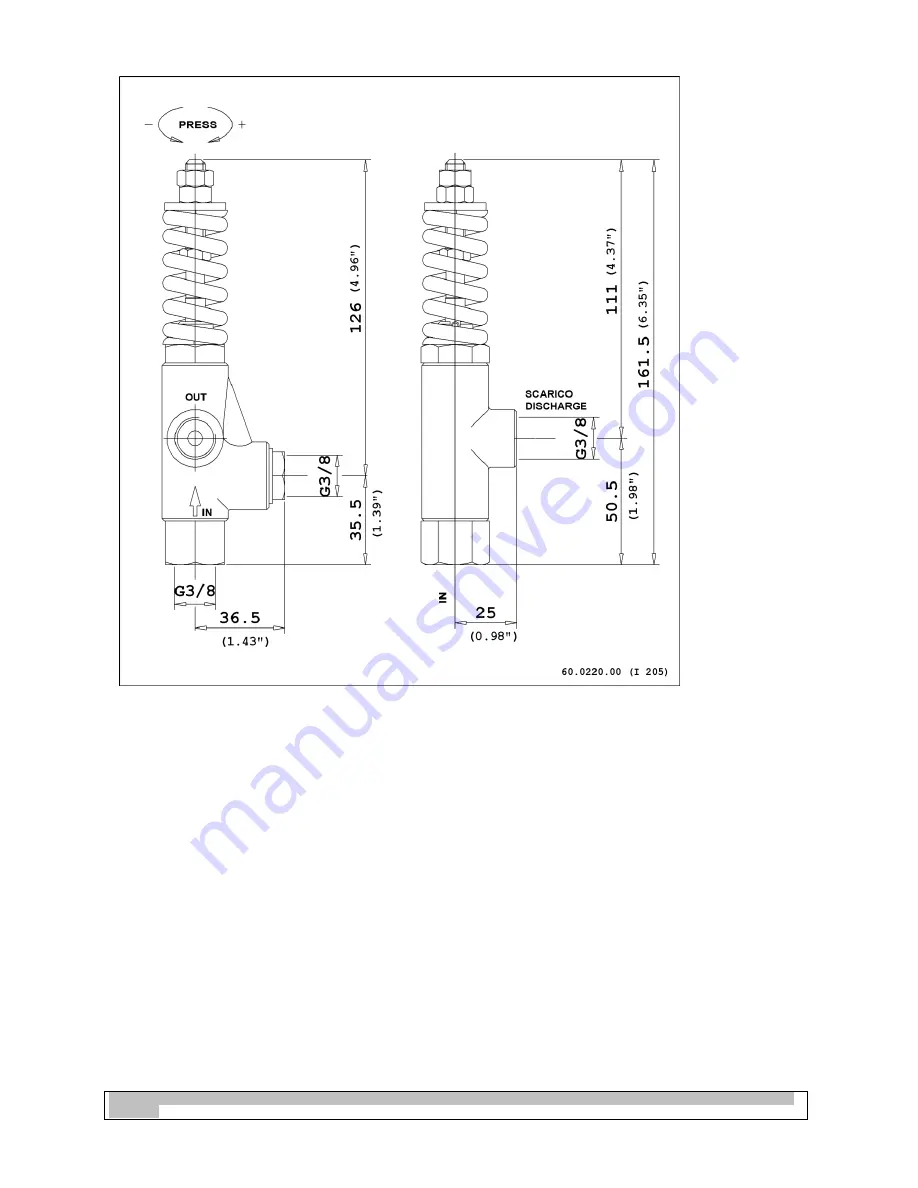

DIMENSIONAL DRAWING.

INSTRUCTIONS

SELECTION

This product is to be utilized with clean fresh water, even slightly additivated with normal detergents. For use involving different or

corrosive liquids, contact the PA Technical department. Choose the valve in line with the data of nominal running (system rated

pressure, max flow and max temperature). In any case, the pressure of the machine should not exceed the permissible pressure rate

imprimed on the valve.The feed through the lower fitting is possible with a reduced flow rate (see point 1). When in use as pressure

regulator, adopt a nozzle that allows a bypass of at least 5% of the total flow, bearing in mind that a worn out nozzle causes pressure

loss. The valve, assembled in line with these indications, avoids pressure spikes whilst the machine is in operation.

INSTALLATION

This accessory, on a system that produces hot water, must be fitted

in front of the heat generator

.

As a SAFETY VALVE: in the case when frequently combined with unloader valves and low pressure in the pump, it has to be fitted in

the section that remains pressurized when the gun is shut off.

As a PRESSURE REGULATOR: maintains the pressure in the system steady during flow changes.

Always

install with the correct

specifications when combined with a safety valve. In case of discharge in the tank or directly into the pump, it is necessary to provide

devices capable to prevent damaging turbolence to the liquid flow.

OPERATIONS

The discharge should be returned to a baffled tank. If, on the contrary, the pump is fed directly from the water mains, it is advisable to

install a pressure reducing valve, before the pump, to avoid dangerous pressure spikes which could badly damage manifolds and

suction valves. In case of extended conditions of bypass directed to the suction side of the pump, it is recommended to install a thermal

valve (VT3 or VT6) to avoid dangerous water temperature build-up.

PRESSURE ADJUSTMENT/SETTING

As a SAFETY VALVE: the adjustment has to be made in such a way that the pressure setting is not superior to the system working

pressure and its accessories; this prevents the arisal of numerous pressure increases in hot water systems and static pressure (gun

shut off).

As a PRESSURE REGULATOR: adjust the valve when the system is pressurized and the gun open. The operation will be easy and

smooth if the proper nozzle is chosen. When rotating the adjustment knob, it has to correspond to a consequent pressure increase;

should the pressure stop increasing before reaching the desired value,

do not insist

, but check the correct nozzle size in relation to

flow and pressure. On reaching the desired pressure, tighten the nut (pos 15) with a drop of paint in order to emphasize any tampering

or slackness.

ATTENTION: The nut (pos 15 nr 1pc) must never be removed otherwise a mechanical safety feature that limits the max pressure

will lack , avoiding serious damage to persons and machine.