1

PLTBC-460

5. STARTING & STOPPING

OPERATION

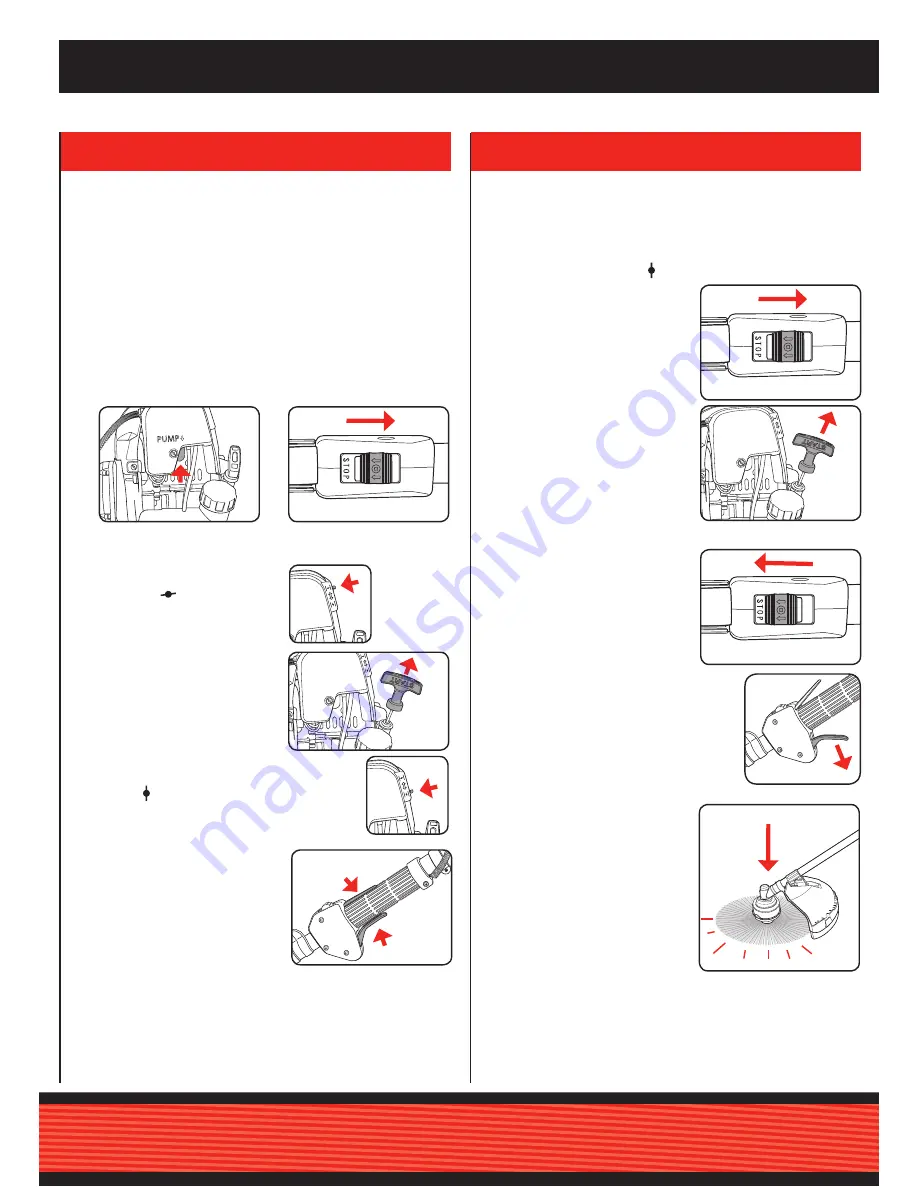

Starting the engine when cold

1. Set the trimmer down on a hard, level surface.

2. Press the fuel pump (primer)

10 times.

4. Set the choke lever to the

on position “

”.

5. With your right hand, pull out the

starter cable until you feel it start

to resist. Pull firmly on the starter

cable 4 times. The trimmer should

start.

6. Once the engine has started, move the choke

lever to “

” (choke off) and allow the trimmer to

warm up for approx. 10 seconds.

Note:

If the engine does not start up,

repeat steps 4-6 above.

7. With the engine running depress the

throttle for operation

Note:

Always pull the starter cord out in a straight line. If it is pulled out at

an angle, then friction will occur on the eyelet. As a result of this friction,

the cable will become frayed and will wear away faster. Always hold the

starter handle when the cable retracts. Never allow the cable to snap

back when it has been pulled out.

Pre-startup checks

1. Ensure that the safety guard, shaft and forward handle are fitted and

are secure.

2. Check that the blade is not damaged if installed.

3. Make sure that the harness is connected and adjusted to the correct

height

4. Ensure that there is sufficient fuel and oil in their tanks before starting

the engine.

Starting the engine when warm

The line trimmer is fitted with a clutch that will allow the engine to idle

without the attachment turning. This prevents injuries while starting the

engine.

1. Leave the choke in the run “

” position (choke off). Set the trimmer

down on a hard, level surface.

2. Move the Ignition switch forward,

away from “STOP”.

3. With your left hand, hold the trimmer

firmly, but do not

depress the throttle lever.

4. With your right hand, pull out the

starter cable until you feel it start

to resist. Pull firmly on the starter

cable. The trimmer should start

after 1-2 pulls If the trimmer does

not start after 6 pulls, repeat steps

1 – 7 of the procedure for

starting

the engine when cold

.

Switching off the engine

Emergency Stop procedure:

If it becomes necessary to stop the

trimmer immediately, set the Ignition

switch to “STOP”.

Normal procedure:

Let go of the throttle lever and wait until the

engine has changed to idling speed. Then set

the Ignition switch to “STOP”.

Extending the cutting line

To extend the cutting line, run the

engine at full speed and tap the

line spool on the ground. This will

automatically extend the line. The

blade on the safety guard will cut the

line to the appropriate length.

3. Move the Ignition switch forward,

away from “STOP”.

x10

x4