27

Outdoor Lifestyles by Hearth & Home Technologies, Inc. • TWILIGHT-II-MOD • 2290-900 Rev. C • 7/12

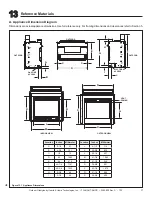

Figure 9.3 Fan Wiring Diagram

D. Optional Accessories

Optional fan and remote control kits require that 110-120

VAC be wired to the factory installed junction box before

the appliance is permanently installed. See Figure 9.3.

Fan Installation

Fan should be positioned on the left side (as viewed from

appliance interior side. See Figure 9.2.

NOTE:

It is rec-

ommended fan be installed prior to gas line installation.

Wall Switch

Position the wall switch in the desired position on a wall.

Run a maximum of 25 feet (7.8 m) or less length of 18

A.W.G. minimum wire and connect it to the appliance ON/

OFF switch pigtails.

NOTE: If any of the original wire as supplied

with the appliance must be replaced, it must be

replaced with the type 105

o

C rated wire.

Figure 9.2 Fan location

SEE DETAIL A

WIRE LEAD

2 FEMALE ENDS

PLUG AND WIRE

ASSEMBLY

JUNCTION BOX

6 FT.

APPROX.

TEMPERATURE

SENSOR SWITCH

FAN SPEED

CONTROL

(RHEOSTAT)

DETAIL A

WIRE LEAD

1 MALE END

1 FEMALE END

6 FT.

APPROX.

FAN KIT

#GFK-160T

FAN

DRIP

TRAY

APPLIANCE

LEFT SIDE

APPLIANCE INTERIOR SIDE