No. U5260

P. 18 / 27

8. MAINTENANCE AND TROUBLESHOOTING (continued)

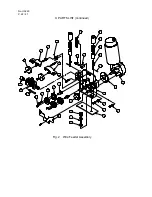

< Schematic Diagram>

8.2

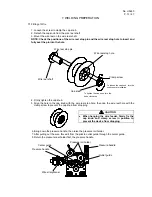

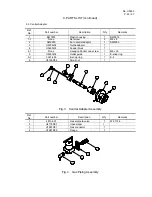

Replacing of the Outlet Guide

Follow the procedures below when replacing the outlet guide.

1. Bring down the pressure handle first, and then lift the

pressure roll holder.

2. Forcibly insert a flathead screwdriver, etc. into the space

between the outlet guide and the snap ring to remove the

snap ring while holding the snap ring with long-nose pliers.

3. Remove the outlet guide by pushing it toward the torch

socket.

4. Insert a new outlet guide from the direction of the torch

socket, and then place the snap ring under the new outlet

guide.

5. Return the pressure roll holder first, the pressure handle.

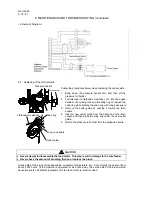

CAUTION

●

Never attempt to disassemble the feed motor. This may result in damage to the wire feeder.

●

Never check the amount of brushing friction or replace the brush.

Service life of the brush varies depending on ambient temperature, etc., but normally the service life is

about 4,000 hours. (If the machine is operated for six hours a day, the service life of the brush will be

about two years). Periodical replacement of the feed motor is recommended.

Pressure handle

Flathead screwdriver

Long-nose pliers

Outlet guide

Snap ring

Torch socket