www.osram-os.com

9 / 18

2020-06-04 | Document No.: AN149

For the connection to the heat sink, please use thermal interface material (for

detailed information on thermal interface material, please refer to Application

Note “AN053_Thermal management of OSRAM OSTAR

®

Projection light

sources”). The devices can be connected to the heat sink with a screw.

When mounting the MPCB to the frame or heatsink by means of a screw, metric

cylindrical head screws M1.4 can be used for the mounting and it is generally

recommended that a locking compound are used for each screw. When

mounting the screws (M1.4), it is recommended that you check on the maximum

torque with the screw supplier. Additionally, to avoid MPCB bending which can

have an adverse effect on the thermal interface material and the LED itself, a

maximum torque of 0.2 Nm should be used. There are 4 holes on the MPCB, and

it is recommended to use 2 diagonal holes for mounting and another 2 holes for

aligning them with the register pins.

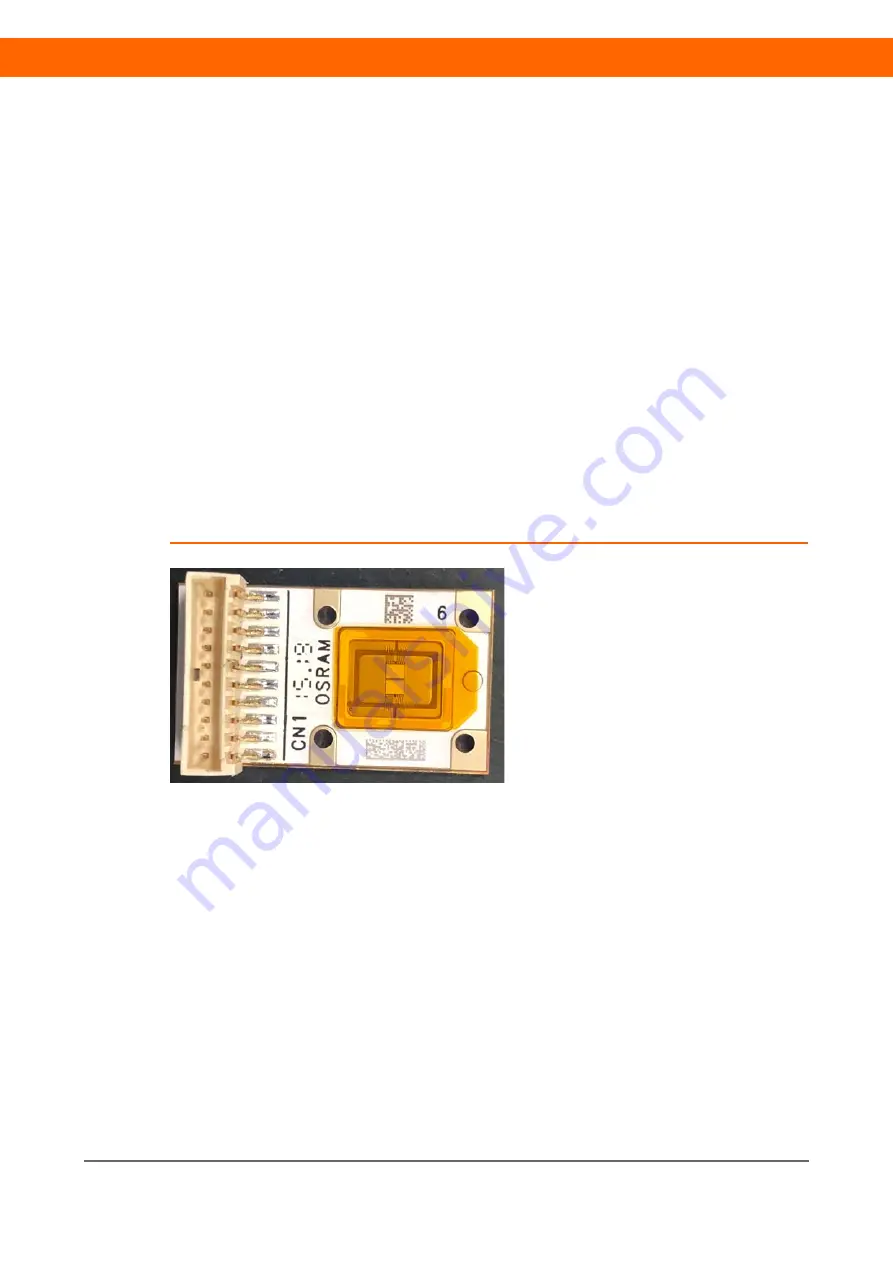

Assembly of the connector

In order to be able to connect the individual components, the IMS provides pins

for assembling a connector. The recommended connector for each component

can be found in the respective data sheet. Figure 9 shows an assembled

connector.

Figure 9: Assembled connector

It is common in industry to use carriers or pallets for the entire SMT assembly

process (solder paste printing, connector placement, reflow soldering) when

processing PCB-based components. These carriers are typically made of highly

heat-resistant, fiber-reinforced material. The cut-outs, which fit the component

precisely, hold the components in place. This enables a stable and reproducible

assembly with a good soldering process. Figure 10 shows a sketch of a possible

carrier.