8

2.10 Pipe connections

Before connecting the cold supply (3), flush the

cold supply pipework of all flux and debris. Lift off

the cylinder lid to allow access to the combina-

tion valve and other connections.

2.11 Vessel connections

Check the expansion vessel(s) and hose connec-

tions are tight. SX 300: Fit the expansion vessel

and bracket on a suitable wall close to the cyl-

inder.

2.12 Remove the template

Position the cylinder to meet the heating and do-

mestic water pipes.

2.13 Combination valve

The combination valve at the top of the cylinder

is factory fitted and is water-tight. If necessary it

can be rotated in either direction to suit the con-

necting pipework, up to half a turn without losing

its seal.

2.14 Cold mains supply

Connect the cold mains supply to the combi-

nation valve cold feed (see illustration below).

The OSO unvented unit is designed for use with

supply pressure up to 8 bar. For water pressures

above 8 bar an additional pressure reducing valve

must be fitted to the cold water supply pipe.

2..15 Hot water outlet

Connect the hot water distribution pipe to the

combination valve hot water outlet (see illustra-

tion).

2.16 Balanced cold water supply (optional)

If no balanced cold supply is required, tighten the

supplied blanking cap.

!

Do not use the balanced cold connection

to feed any outlets other than mixer showers.

Under no circumstances use the balanced cold

connection to feed all cold water outlets as

this practice contravenes Section 10 of water

regulations.

!

If a balanced mains pressure cold water supply is

required to a shower or bidet (over rim type only,

ascending spray type requires type AA, AB or AD

air gap), remove blanking cap and connect to the

shower or bidet cold supply (2) on the combina-

tion valve. Major shower manufacturers advise

fitting a mini expansion vessel in the balanced

cold supply pipework to accommodate thermal

expansion and prevent tightening of shower con-

trols.

2.17 Expansion vessel (300 l. only)

Site the expansion vessel on the wall using the

supplied bracket and connect to the expansion

vessel connecting point (13) on the multifunction

valve with copper pipe.

2.18 Flexible Y-hose

The flexible Y-hose (11) is preformed to the cor-

rect shape. Connect the inlet ends to the expan-

sion relief valve (6) and the temperature and

pressure relief valve (8).

2.19 Tundish

Recommended position of the tundish (12) is to

the left of the cylinder as seen from the front.

Connect the tundish inlet to the outlet end of the

flexible Y-hose (11). Tundish should be visible and

positioned away from electrical devices. Tundish

can be secured with supplied screws.

2.20 Secondary return (optional)

If a secondary return is connected reduce ther-

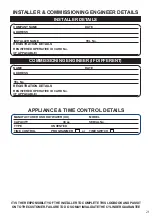

No. Description

Dim.

1

Domestic hot water outlet (DHW out)

ø22 mm

2

Balanced cold water connection (Bal. CW) ø22 mm

3

Cold water main supply inlet (CW in)

ø22 mm

1 2

3

13

8

11

12

6