6

4.6. INPUT PROTECTION

A provision is built into the preamplifier to protect

the input FET stage from damage when high-

voltage transients are applied to its input. These

transients can result from any one or more of many

causes, including detector breakdown, moisture

condensation on the input connector, short circuits

or uncharged capacitance connected across the

input while bias is being applied through the

preamplifier, or disconnection of a bias voltage

without first reducing it gradually to zero.

The protection circuit is installed in the preamplifier

when the unit is shipped from the factory. Although

it offers protection to the FET, it also causes some

degradation of the noise performance of the

preamplifier, which increases as detector capacity

increases.

With the protection circuit in, the collector lead of

Q11 is attached to the center tap of the two series

input resistors to the FET, R39 and R5. Transistor

Q11 is connected as a diode, with both the base

and the emitter tied through R8 to ground. This

prevents the voltage in the input circuit from rising

beyond the safe limit for the FET input. To take the

protection circuit out, simply remove the collector

lead of Q11 from its circuit connection and install a

wire jumper across R39 and R5.

Inherent to all high-speed charge-sensitive

preamplifiers is the problem of keeping the total

system stable while interconnecting the detector

and preamplifier with long cables. To help ease this

problem and permit more flexibility for installations,

the protection circuit is designed to serve not only

as a protection for the FET input but also to

terminate the input cable in a nominal 100

S

. So it

is recommended that the protection circuit be left in

whenever possible.

In order to take full advantage of the risetime

capabilities of the 142PC for timing experiments

(typical risetimes of 25 to 150 ns for detector

capacities from 1 to 100 pF), the total cable length

should be kept as short as possible, even though it

is terminated. Due to vagaries in the system

installation

!

ground loops, stray inductances,

etc.

!

and since the maximum cable length is a

factor in the input capacitance to the preamplifier,

it is not possible to give absolute numbers.

Generally, two feet is a typical maximum length to

obtain fastest risetimes for low detector capacities.

Of course, the system can be compensated for

cable lengths of up to 5 or 6 feet but slower

risetimes will be obtained. The screwdriver

adjustment inside the case can be used to stabilize

the system and minimize the pulse risetime.

5. MAINTENANCE INSTRUCTIONS

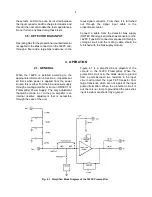

5.1. TESTING PERFORMANCE

As ordinarily used in a counting or spectroscopy

system, the preamplifier is one part of a series

system involving the source of particles to be

analyzed, the detector, the preamplifier, the main

amplifier, and the pulse height analyzer. When

proper results are not being obtained and tests for

proper performance of the preamplifier and the

other components are indicated, it is important to

realize that rapid and logical testing is possible only

when the individual components are separated from

the system. In proving the performance of the

preamplifier, it should be removed from the system

and be dealt with alone, by providing a known

electrical input signal and testing for the proper

output signals with an oscilloscope as specified in

the following steps.

1. Furnish a voltage pulse to the Test Pulse

connector as outlined in Section 3.4. The polarity of

the test pulse signal should agree with the expected

signal input polarity from a proportional counter.

2. Using a calibrated pulser, the 142PC output,

either E or T, should be inverted from the input and

have a nominal scale factor of 300 mV per 1 MeV

equivalent energy (Si).

3. The noise contribution of the preamplifier may be

verified by two basic methods. In either case, the

Summary of Contents for 142PC

Page 4: ...iv...

Page 8: ...viii...