Summary of Contents for BUG

Page 2: ......

Page 22: ...Base 869 BRAKING LOCKS UNLOCKS Base 856 BRAKING LOCKS UNLOCKS 20 104 ...

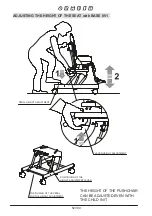

Page 31: ...ADJUSTING THE DEPTH OF THE SEAT WRENCH 29 104 ...

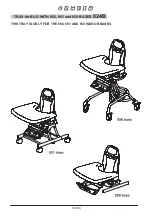

Page 32: ...Bug seat with 4 WHEEL base 869 30 104 ...

Page 41: ...Bug seat with INDOOR base 856 39 104 ...

Page 53: ...THE SEAT IS NOT REVERSIBLE WITH INDOOR BASE 851 Base 850 Base 851 51 104 ...

Page 55: ...MINIMUM HEIGHT MAXIMUM HEIGHT BASE 851 BRAKING LOCKS UNLOCKS 53 104 ...

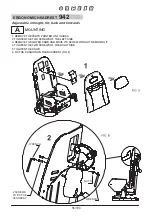

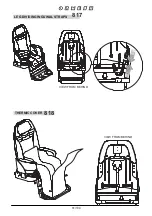

Page 59: ...WRENCH WRENCH NUTS 2 SCREWS TO FIX THE HEADREST 57 104 ...

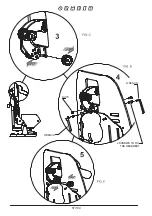

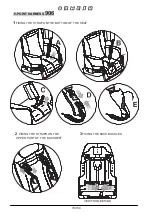

Page 63: ...LEG DIVIDING INGUINAL STRAPS VIEW FROM BEHIND THERMIC COVER VIEW FROM BEHIND 817 818 61 104 ...

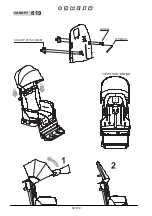

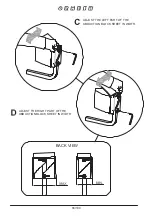

Page 64: ...CANOPY CANOPY ATTACHMENT SCREW WRENCH VIEW FROM BEHIND 819 62 104 ...

Page 66: ...FOOT STRAPS Padded ABDUCTION BLOCK TIGHTEN THE KNOB 827 834 WRENCH 64 104 ...

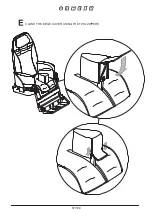

Page 69: ...CLOSE THE EDGE COVER USING THE TWO ZIPPERS 67 104 ...

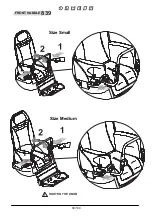

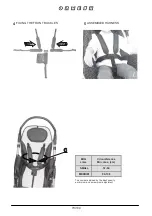

Page 70: ...FRONT HANDLE TIGHTEN THE KNOB 839 Size Small Size Medium 68 104 ...

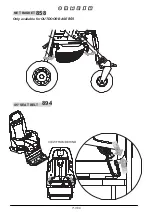

Page 73: ...NET BASKET Only available for OUTDOOR BASE 869 45 SEAT BELT VIEW FROM BEHIND 858 894 71 104 ...

Page 75: ...TRAY 824 knob knob VIEW FROM BELOW locking lever TIGHTEN THE KNOB 73 104 ...

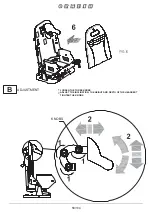

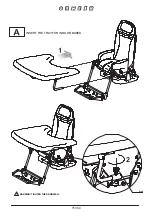

Page 77: ...INSERT THE TRAY FOR INDOOR BASES knob WARNING TIGHTEN THE KNOB WELL 75 104 ...

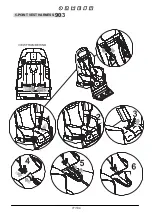

Page 79: ...5 POINT VEST HARNESS VIEW FROM BEHIND 903 77 104 ...

Page 85: ...PADDED COVERING for FOOTPLATE VIEW FROM BEHIND OF THE FOOTPLATE 892 83 104 ...

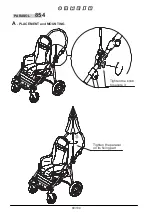

Page 92: ...NUT M6 ADJUSTABLE BUSHING SCREW M6X25 SCREW M6X25 HOW TO FIX THE ADJUSTABLE BUSHING 90 104 ...

Page 97: ...ADJUSTMENT IN DEPTH nut M5 wrench REAR VIEW 95 104 ...

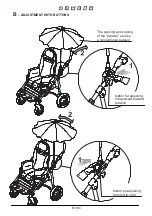

Page 101: ...BOTTLE HOLDER 922 99 104 ...

Page 107: ......