HM-40089-3

5-phase stepping motor unit

CRK

Series

Built-in Controller

Information

Thank you for purchasing an Oriental Motor product.

1

Introduction

Before use

Only qualified personnel should work with the product. Use the product correctly

after thoroughly reading the section “Safety precautions”.

The product described in this manual has been designed and manufactured for

use in general industrial machinery, and must not be used for any other purpose.

For the driver’s power supply, use a DC power supply with reinforced insulation

on its primary and secondary sides.

Oriental Motor Co., Ltd. is not responsible for any damage caused through

failure to observe this warning.

Overview of the product

The

CRK

series built-in controller is a unit product consisting of a 5-phase

stepping motor driver with built-in controller function and a 5-phase stepping

motor offering high torque with low vibration. The driver supports I/O control and

RS-485 communication.

Set the operating data and parameters using the optional data-setter

OPX-2A

(sold separately) or RS-485 communication.

Hazardous substances

RoHS (Directive 2002/95/EC 27Jan.2003) compliant

Checking the product

Verify that the items listed below are included. Report any missing or damaged

items to the branch or sales office from which you purchased the product.

•

Motor .........................................................................1 unit

•

Driver.........................................................................1 unit

•

CN1 connector (3 pins)..............................................1 pc.

•

CN2 connector cable [1 m (3.3 ft.)]............................ 1 pc.

•

CN4 connector lead wire [0.6 m (2 ft.)] ...................... 1 pc.

•

OPERATING MANUAL (CD-ROM)............................ 1 pc.

•

Information (this document) ....................................... 1 copy

Names and functions of parts

●

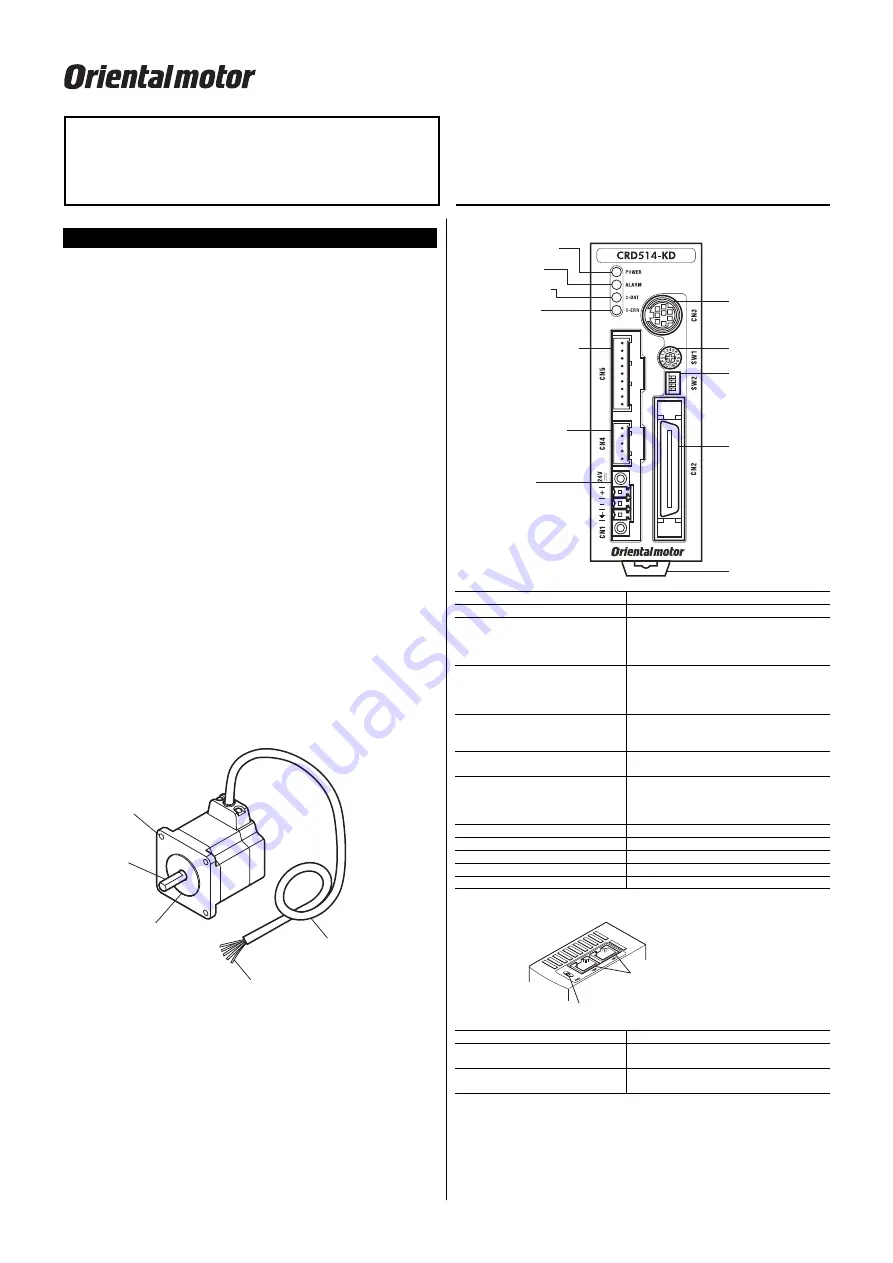

Motor

Illustration shows the

PK56

type.

Motor cable

Motor lead wires

(5 pcs.: blue, red, orange, green, black)

Mounting hole

(4 locations)

Output shaft

Pilot

●

Front side of the driver

POWER LED (green)

Encoder connector (CN5)

Motor connector (CN4)

Power supply

connector (CN1)

C-ERR LED (red)

C-DAT LED (green)

ALARM LED (red)

Communication

connector (CN3)

Address number

setting switch (SW1)

Function setting

switches (SW2)

I/O signals

connector (CN2)

DIN lever

Name Description

POWER LED (green)

This LED is lit while the main power is input.

ALARM LED (red)

This LED will blink when an alarm generates

(a protective function is triggered). You can

check the generated alarm by counting the

number of times the LED blinks.

C-DAT LED (green)

This LED will blink or illuminate steadily

when the driver is communicating with the

master station properly via RS-485

communication.

C-ERR LED (red)

This LED will illuminate when a RS-485

communication error occurs with the master

station.

Address number setting switch

(SW1)

Set the address number of RS-485

communication.

Function setting switches (SW2)

No.1 to 3: Set the baud rate of RS-485

communication.

No.4: Set the address number of RS-485

communication with SW1.

Power supply connector (CN1)

Connect main power supply (+24 VDC).

I/O signals connector (CN2)

Connect I/O signals.

Communication connector (CN3)

Connect a data setter

OPX-2A

.

Motor connector (CN4)

Connect the motor.

Encoder connector (CN5)

Connect the encoder.

●

Upper side of the driver

Terminal resistor setting switch (SW3)

RS-485 communication

connector (CN6/CN7)

Name Description

Terminal resistor setting switch

(SW3)

Set the terminal resistor (120

Ω

) of RS-485

communication.

RS-485 communication connector

(CN6/CN7)

Connect the RS-485 communication cable.