5

y

When connecting a power supply to multiple drivers in a daisy

chain, make sure that the total input current of the drivers is 6.5 A or

less. Exceeding 6.5 A may cause damage to the driver.

y

Connect the connectors securely. Insecure connections may cause

malfunction or damage to the motor or driver.

y

When connecting the connection cable, secure the cable so that no

load is applied to the CN1 to CN3 connectors. Applying a load to the

connector may result in a connection failure, and the driver may not

operate properly.

y

Keep 0.5 m (1.6 ft.) or less for the wiring distance between the motor

and driver. To extend more than 0.5 m (1.6 ft.) may result in increase

of the electrical noise emitted from the driver.

y

Keep 5 m (16.4 ft.) or less for the total wiring distance (*) of the

power/communication cable. To extend more than 5 m (16.4 ft.)

causes the driver to be affected easily by electrical noise.

* The total wiring distance refers to a wiring distance from the power

supply or the host controller, whichever the length of the cable

connected to the CN1 connector is longer, to the driver located at

the end. In the figure of the connection example, the total wiring

distance is from the host controller to the CN1 connector of the third

driver.

y

Before connecting or disconnecting the connector, turn off the main

power supply of the driver, and check the PWR/ALM LED has been

turned off.

y

When disconnecting the connector, pull off while pressing the latch

on the connector.

y

Connect GND of the power supply and GND of RS-485

communication to the same ground.

Connecting the main power supply, RS-485

communication, and termination resistor

(CN1, CN2)

Connect the main power supply and the RS-485 communication signal to

CN1 or CN2. When multiple drivers are used, they can be connected in a daisy

chain using CN1 or CN2. Power/communication cables are also available in

our products. Refer to p.8 for details.

The CN1 connector and CN2 connector are not electrically insulated.

You can connect either of the two connectors.

z

Applicable connector

Type

Model

Connector housing

105308-1204 (Molex Incorporated)

Contact

105300-2200 (Molex Incorporated)

Designated crimping tool 63827-5600 (Molex Incorporated)

Applicable lead wire

y

AWG22 to 20 (0.3 to 0.5 mm

2

)

y

Outer sheath diameter:

ø1.3 to 1.55 mm (0.05 to 0.06 in.)

y

Stripping length of wire insulation:

2.5 to 3.5 mm (0.1 to 0.14 in.)

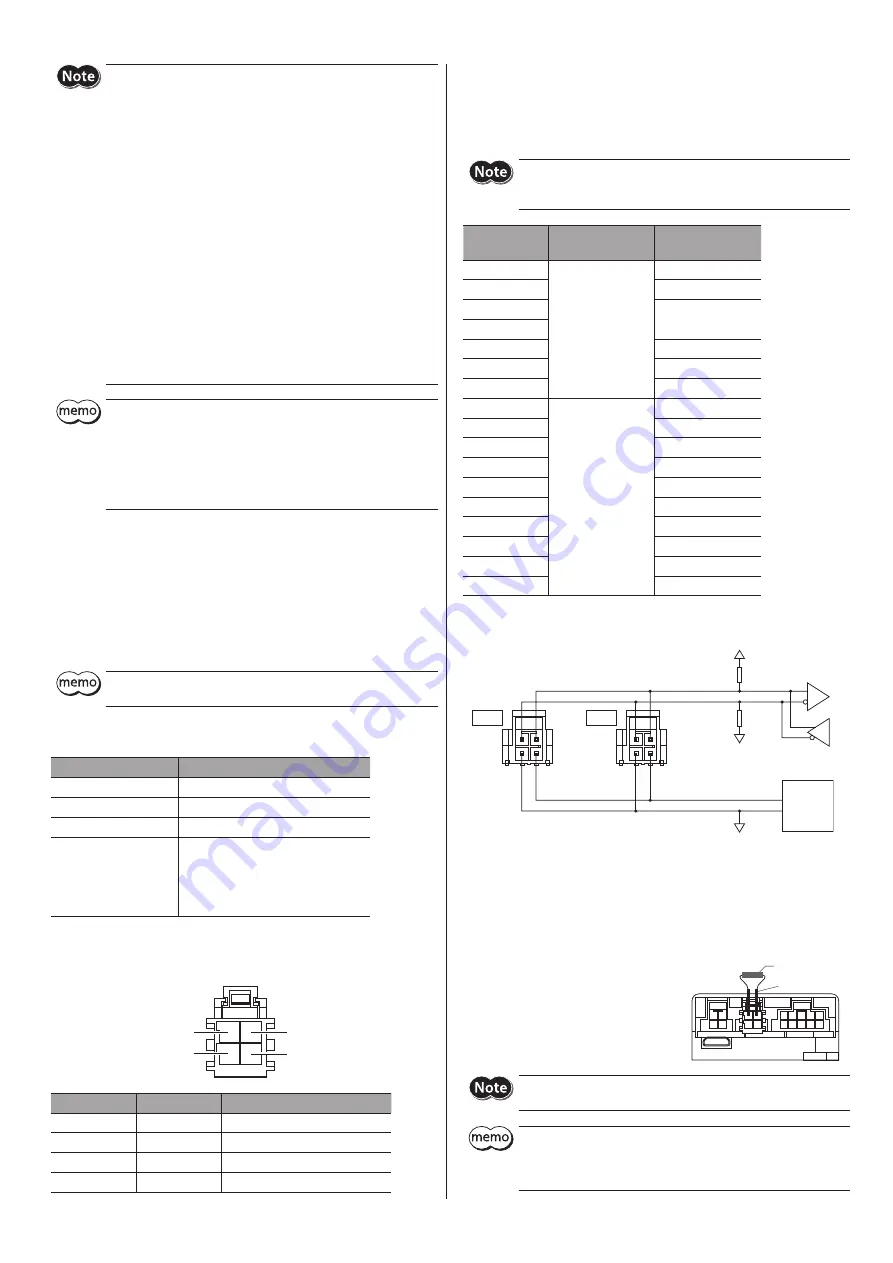

z

Pin assignment

The figure shows the view from the contact insertion side.

1

3

2

4

Pin number

Signal name

Description

1

TR+

RS-485 communication signal (+)

2

TR−

RS-485 communication signal (−)

3

VIN

+24 VDC/+48 VDC

4

GND

Power supply GND

z

Power supply current capacity

The power supply current capacity varies depending on the product to be

combined.

When using the

EAS

Series, the

EAC

Series, and the

EZS

Series, check with

reference to the equipped motor model name.

When connecting a power supply to multiple drivers in a daisy chain,

make sure that the total input current of the drivers is 6.5 A or less.

Exceeding 6.5 A may cause damage to the driver.

Model

Input power supply

voltage

Power supply

current capacity

AZM14

24 VDC±5 %

0.4 A or more

AZM15

0.5 A or more

AZM24

1.4 A or more

AZM26

DGM60

1.4 A or more

DR28

1.3 A or more

EH4

1.4 A or more

AZM46

24 VDC±5 %

48 VDC±5 %

1.6 A or more

AZM48

2.1 A or more

AZM66

3.7 A or more

AZM69

3.5 A or more

DGB85

1.6 A or more

DGB130

3.7 A or more

DGM85

1.6 A or more

DGM130

3.7 A or more

DRSM42

1.5 A or more

DRSM60

2.6 A or more

z

Internal input circuit

100 kΩ

100 kΩ

0 V

Motor

Driver

Circuit

0 V

TR+

VIN

TR−

GND

+5 V

TR+

VIN

TR−

GND

CN2

CN1

z

Connecting the termination resistor

Connect a resistor between the TR+ terminal and the TR− terminal of CN1 or

CN2 for a driver located the farthest away (positioned at the end) from the

host controller.

Connecting method

1. Connect the lead wires to the resistor.

2. Connect the lead wires between the

TR+ terminal and the TR− terminal of

CN1 or CN2.

Resistor

Lead wires

Be sure to connect a resistor between the TR+ terminal and the TR−

terminal. Incorrect connection may cause damage to the resistor.

y

For a resistor, use a metal film resistor of 120 Ω, 1/2 W or more.

y

Do not crimp a resistor directly to the contacts. The contacts are

designed on the assumption that the stranded wire is crimped. The

resistor cannot be crimped sufficiently due to a single wire.