BTP-R880NP Installation manual

- 17 -

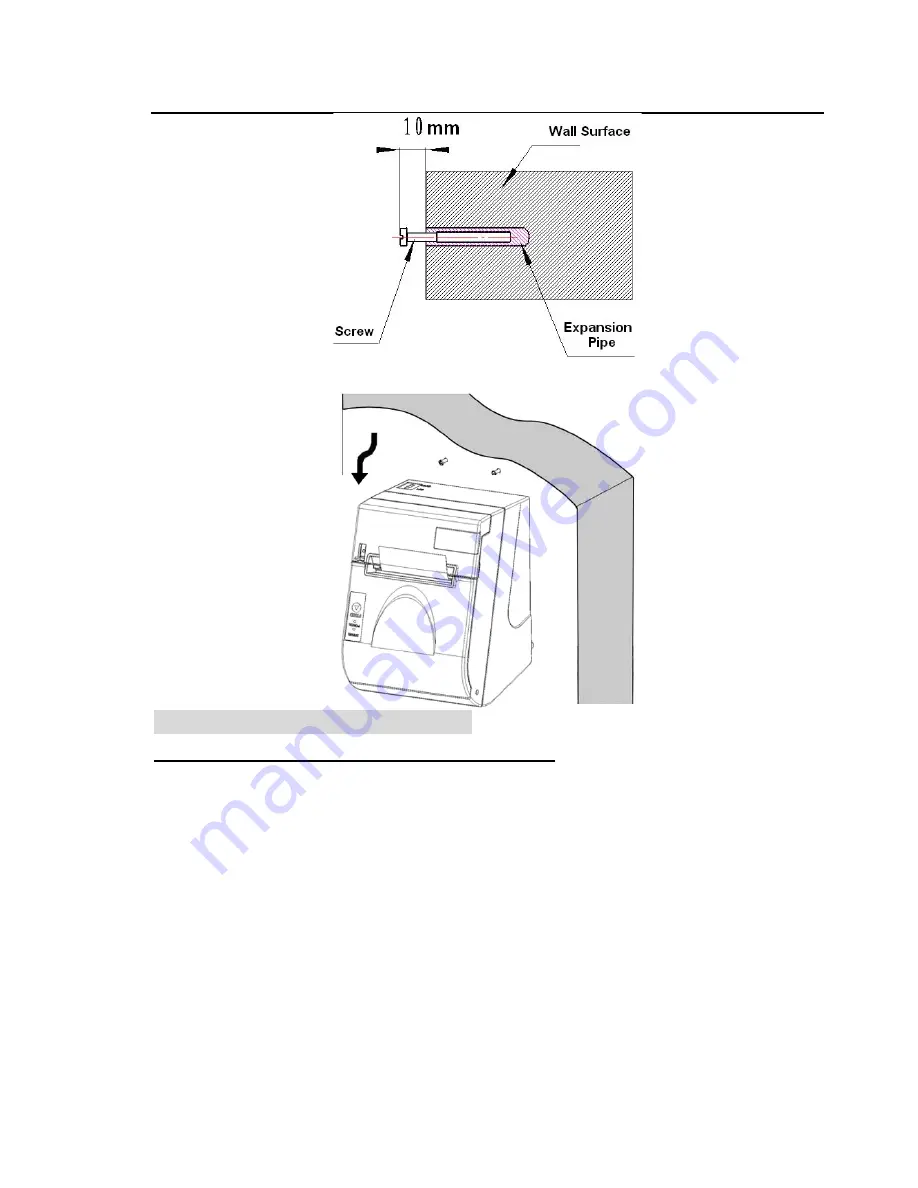

4) Regulate the paper near end sensor (Please refer to 3.4.1), Mount the printer as

figure.

4) Every choice has a number, which indicates the number of times the FEED

button has to be shortly pressed. After this, the choice is validated by an additional,

but longer press of the FEED button (1 sec).

3) The procedure consists of several sub-menus and step-by-step working is

needed.

2) After the printer has printed the configuration sheet, press and hold the FEED

button to configure the printer. The main menu for the key-stroke setting procedure

is printed.

Parameter setting (configuring) by Feed button

1)

Hold the FEED button pressed while switching the printer on.

7 Configuration setting function

After all settings have been done, they are stored in the printer by stepping back

through the submenus to the main menu by using the number “1” plus additional

press for validation.