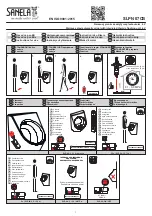

2.

Ø 32 mm

Ø 25 mm

Ø 16-20 mm

Ø 12 mm

Cut the cone depending on the diameter

of the hose.

3.

4.

CAUTION

Cut the corrugated sleeve as

close as possible to the water

tight seal.

<50 mm

Cut the corrugated sleeves.

5.

NOTICE

Anchors provided by Customer.

6.

Secure Pipe in slot in stud and anchor

with Pipe Clamp.

Pre-installation

23

Summary of Contents for Oas

Page 1: ...PRE I NSTALLATION O A S W A L L I N T E G R A T E D R 3 5 06 0009 Publication date 2020 02 27 ...

Page 4: ...This page is intentionally left blank ...

Page 23: ...7 4 8 Adjust x4 M3 5 5 mm driver Secure Pre installation 19 ...

Page 29: ...C E R T I F I E D S P A C E T E C H N O L O G Y ...