OPTIMUM

M A S C H I N E N - G E R M A N Y

Maintenance

Version 1.0 dated 2015-06-18

Page 30

Original operating instructions

S275N | S275NV

GB

5

Maintenance

ATTENTION!

Properly performed regular maintenance is an essential prerequisite for

operational safety,

failure-free operation,

long service life of the metal belt saw and

the quality of the products which you manufacture.

Installations and equipment from other manufacturers must also be in good order and condition.

5.1

Safety

WARNING!

The consequences of incorrect maintenance and repair work may include:

very serious injury to personnel working on the metal belt saw,

damage to the metal belt saw.

Only qualified staff should carry out maintenance and repair work on the metal belt saw.

Electrical systems and operating materials may only be installed, modified and repaired

by a trained electrician or supervised and under the control of a trained electrician and

must comply with electrotechnical regulations.

WARNING!

Do not climb onto or into the machine while working.

5.1.1 Preparation

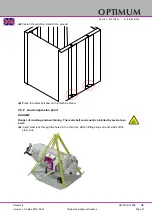

WARNING!

Only work on the metal belt saw when the mains plug is disconnected.

Attach a warning sign.

5.1.2 Restarting

Before restarting, run a safety check.

WARNING!

Before starting the machine, you must check that there is no danger for persons and

that the machine is not damaged.

5.1.3 Cleaning

CAUTION!

Use a chip hook for removal of chips and wear suitable protective gloves.

5.2

Checkup, inspection and maintenance

The type and level of wear depends to a large extent on the individual usage and operating

conditions. Any indicated intervals therefore are only valid for the corresponding approved con-

ditions.