OPTIMUM

M A S C H I N E N - G E R M A N Y

Version 3.1.8 dated 2015-1-27

Page 49

Original operating instructions

BF20V

US

7

Troubleshooting

7.1

Troubleshooting the mill drill

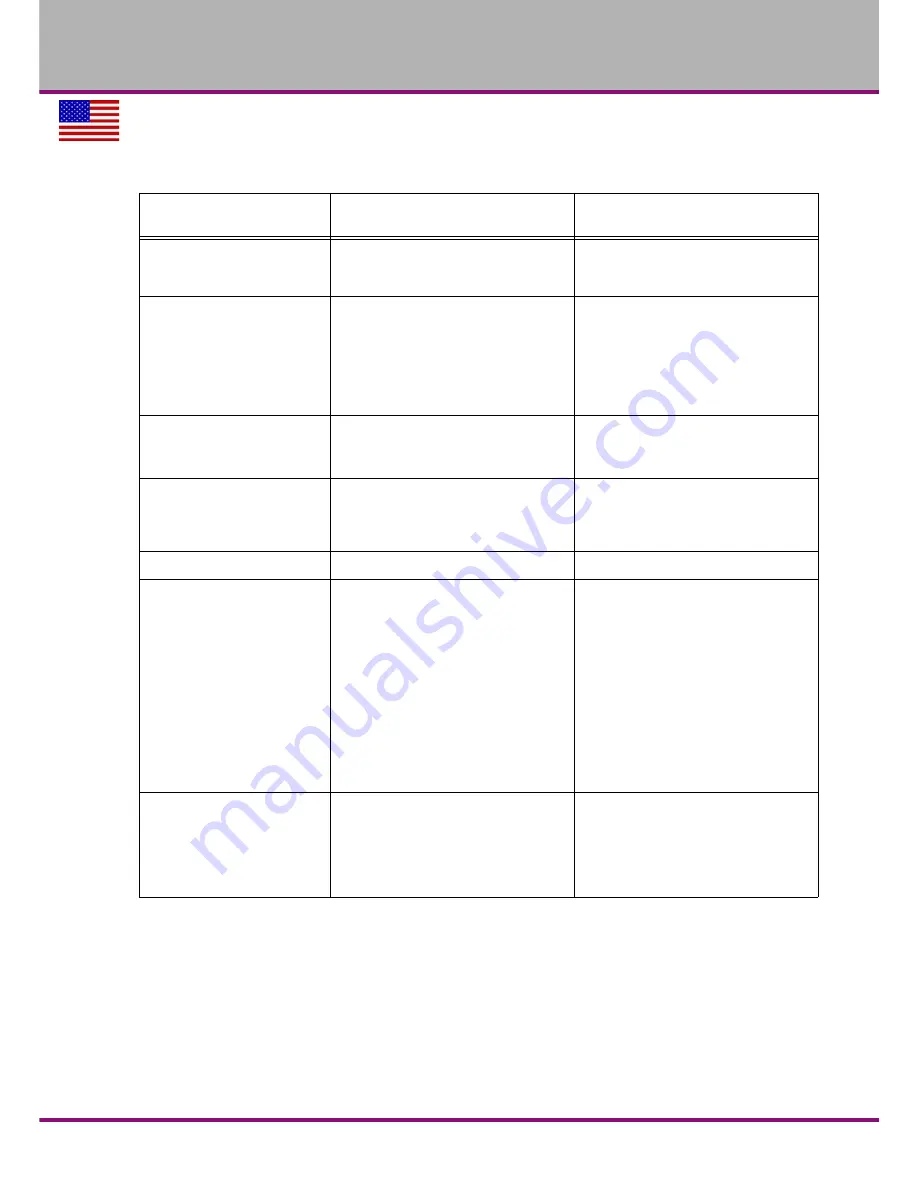

Malfunction

Cause/

possible consequences

Solution

The mill drill does not start

•

Start sequence not followed.

•

"Switching on the mill drill“ on

page 25

•

Have it checked by authorised staff.

Tool "burnt“.

•

Incorrect speed.

•

The chips have not been removed

from the bore hole.

•

Tool blunt.

•

Operating without cooling agent.

•

Select another speed, feed too high.

•

Retract tool more often

•

Sharpen and replace tool.

•

Use coolant.

Impossible to insert holding

taper into the spindle

sleeve.

•

Remove any dirt, grease or oil from

the internal conical surface of the

spindle sleeve or the holding taper.

•

Clean surfaces well.

Keep surfaces free of grease.

Taper cannot be removed

•

Optional MT3 taper seat shrunk on

morse cone.

•

Have the machine heat-up at highest

speed for about two minutes and

then try again to disassemble the

taper.

Motor does not start

•

Defective fuse

•

Have it checked by authorised staff.

Working spindle rattling on

rough workpiece surface

•

Climb milling machining not possible

under the current operating condi-

tions.

•

Clamping lever of the movement

axes not tightened.

•

Loose collet chuck, loose drill chuck,

loose draw-in rod.

•

Tool blunt.

•

Workpiece is not fixed.

•

Excessive slack in bearing.

•

Working spindle goes up and down.

•

Perform conventional milling.

•

Tighten clamping lever

•

Check, retighten.

•

Sharpen or replace tool

•

Secure the workpiece properly.

•

Readjust bearing slack or replace

bearing.

•

Readjust bearing slack or replace

bearing.

Fine feed of spindle sleeve

does not work

•

Fine feed is not correctly activated

•

Clutch of the fine feed does not

engage, is dirty, smeared, worn or

defective

•

"Manual spindle feed with the

fine feed“ on page 30

•

Clean, replace