Version 1.0.1 - 2020-07-23

40

Translation of original instruction

B20 | B25 | B32

EN

B20-

B25-

B32_

GB.

fm

7

Appendix

7.1

Copyright

This document is protected by copyright. All derived rights are reserved, especially those of

translation, re-printing, use of figures, broadcast, reproduction by photo-mechanical or similar

means and recording in data processing systems, either partial or total.

Subject to technical changes without notice.

7.2

Liability claims/warranty

Besides the legal liability claims for defects of the customer towards the seller, the manufac-

turer of the product, OPTIMUM GmbH, Robert-Pfleger-Straße 26, D-96103 Hallstadt, does not

grant any further warranties unless they are listed below or were promised as part of a single

contractual provision.

Liability or warranty claims are processed at OPTIMUM GmbH's discretion either directly or

through one of its dealers.

Any defective products or components of such products will either be repaired or replaced

by components which are free from defects. Ownership of replaced products or compo-

nents is transferred to OPTIMUM Maschinen Germany GmbH.

The automatically generated original proof of purchase which shows the date of purchase,

the type of machine and the serial number, if applicable, is the precondition in order to

assert liability or warranty claims. If the original proof of purchase is not presented, we are

not able to perform any services.

Defects resulting from the following circumstances are excluded from liability and warranty

claims:

- Using the product beyond the technical options and proper use, in particular due to over-

straining of the machine.

- Any defects arising by one's own fault due to faulty operations or if the operating manual

is disregarded.

- Inattentive or incorrect handling and use of improper equipment

- Unauthorized modifications and repairs

- Insufficient installation and safeguarding of the machine

- Disregarding the installation requirements and conditions of use

- atmospheric discharges, overvoltage and lightning strokes as well as chemical influences

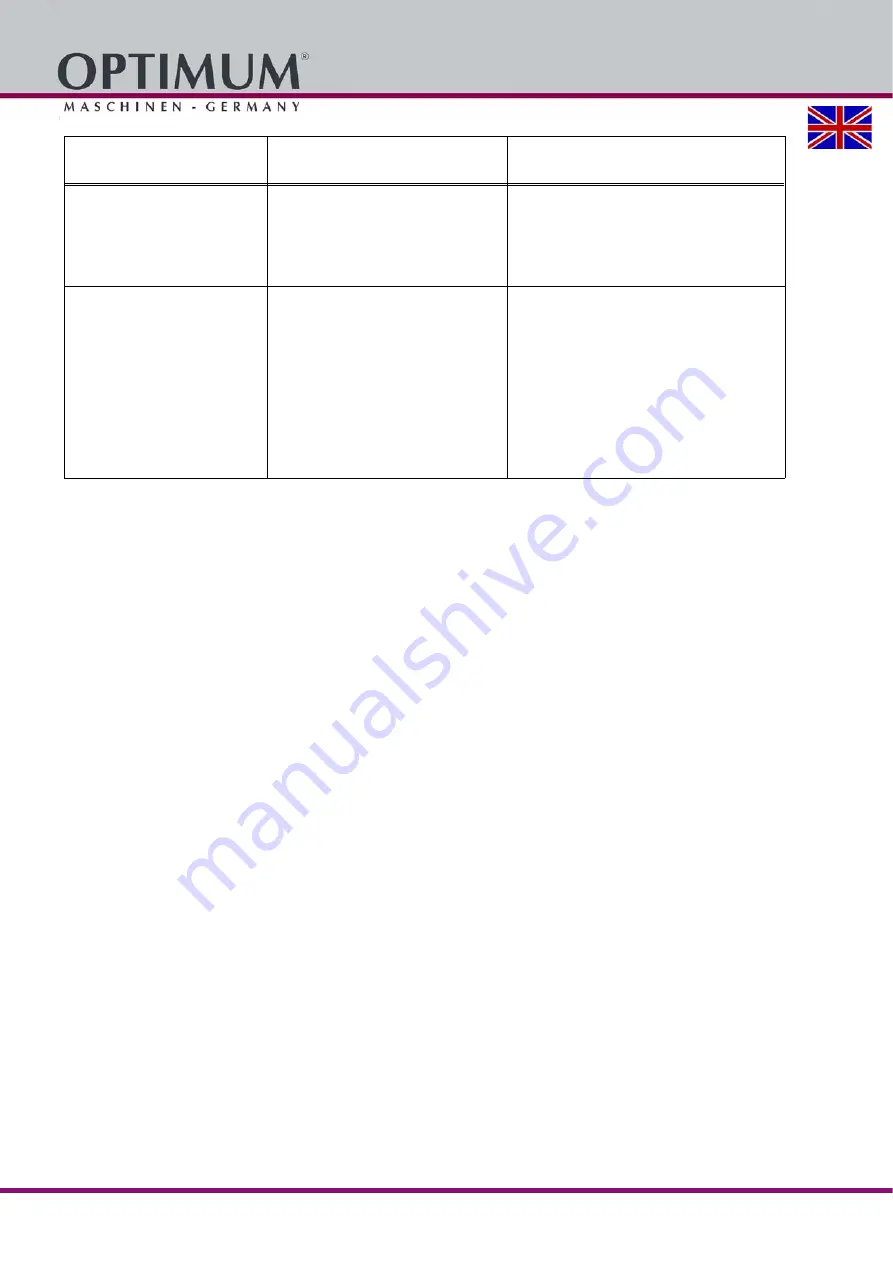

Spindle bearing overheating

•

Bearing worn down

•

Bearing pretension is too high

•

Working at high drilling speed

over a longer period of time.

•

Replacing

•

Increase bearing clearance for fixed

bearing (taper roller bearing)

•

Reduce drill speed and feed rate

Rattle the spindle if the

workpiece surface is rough.

•

Excessive slack in bearing.

•

Spindle moves up and down

•

Adjustment strip loose

•

Clamping chuck is loose

•

Tool is blunt.

•

Workpiece is loose

•

Readjust the bearing slack or

replace the bearing.

•

Readjust bearing clearance (fixed

bearing)?

•

Adjust strip to the correct slack

using the adjusting screw

•

Check, re-tighten

•

Sharpen or renew the tool.

•

Clamp the workpiece firmly.

Malfunction

Cause/

possible effects

Solution