ONLINE ELECTRONICS LTD

ID5000P_5001_A01

Page 16 of 18

5.3.

MODBUS PCB OPTION

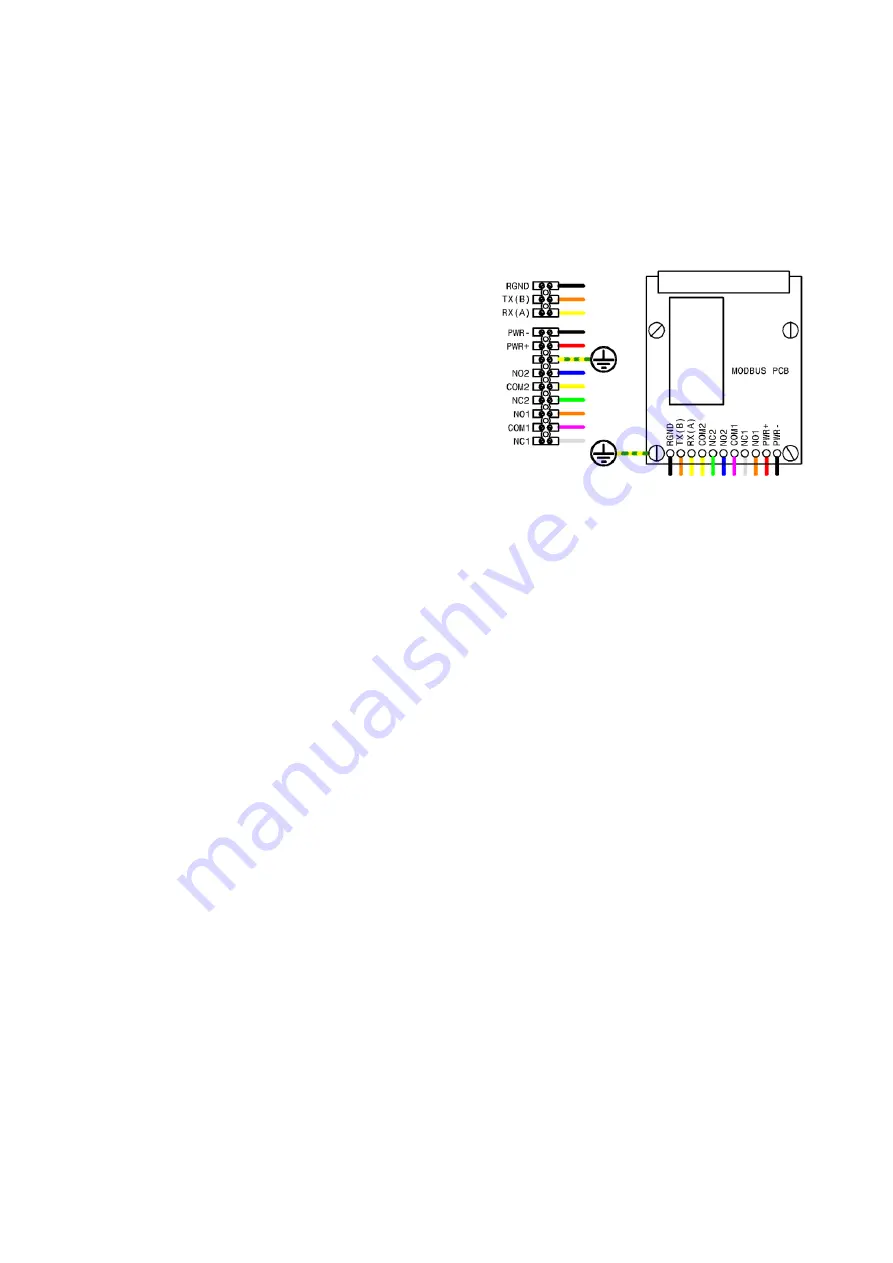

The MODBUS PCB is fitted when a MODBUS interface is required. It also provides connections

for external power, relay output, and a current loop output. The MODBUS PCB should only be

used with an EXTERNAL POWER SUPPLY. Use with a battery pack is not recommended.

The connections to the MODBUS PCB are non-detachable (soldered) and care must be taken

not to damage them if removing the battery compartment. Connections are clearly labelled on

the PCB and are connected to a TERMINAL BLOCK using the wire colours shown below.

RGND - RS485 ground connection

TX(B) - RS485 B connection

RX(A) - RS485 A connection

COM2 - Common contact for relay 2

NC2 - Normally Closed contact for relay 2

NO2 - Normally Open contact for relay 2

COM1 - Positive side of current loop 24VDC supply

NC1 - Negative side of current loop 24VDC supply

NO1 - Do not use this connection

PWR+ - Positive side of external 24VDC supply

PWR- - Negative side of external 24VDC supply

Refer to sections 3.5 RELAY OUTPUT and 3.6 CURRENT LOOP OUTPUT. All power supplies must

provide between 23.0VDC and 25.0VDC. A single power supply may be shared for the positive

side of external supply and the positive side of the current loop supply.

The MODBUS PCB provides a current loop output utilising connections COM1 and NC1 as

shown above. Because relay 1 is used to control the current loop then inverting the relay logic

as per section 3.7.7 SET OUTPUT will also reverse the state of the CURRENT LOOP output.

The only information provided over the MODBUS interface is the status of the relay which is

described in section 3.5 RELAY OUTPUT. Access to this single ‘bit’ of information is accessed

using MODBUS commands:

CMD 2 “Read Discrete Input” at coil 8

CMD 3 “Read Holding Register” at register 0 bit 0.

CMD 4 “Read Input Register” at register 0 bit 0.

Assuming that the relay logic has not been inverted (see section 3.7.7 SET OUTPUT) then the

relay bit will be ‘1’ while the relay is in the DETECTION state and ‘0’ while the relay is in the

LISTENING state.

The MODBUS interface is configured by selecting SET OUTPUT->CONFIGURE MODBUS in the

menu system. There are 3 configurable parameters:

MODBUS address for the unit (if zero – MODBUS disabled)

BAUD rate for communications (9600,19200,38400,57600,115200)

WORD format (no/even/odd parity, 7 or 8 bit word, 1 or 2 stop bits)

If a non-zero address is entered then the MODBUS interface will become active on exit from

the menu and will await commands.