V. General Assembly

Pro 2000 Owners Manual

O.A.S. 2007

c

6

Cyclone

Barrel

Cone

Square to Round

Connects to Inlet

1. Motor/Blower Assembly BXI012309-1ph - - 3ph

1a. Fan Wheel - BWX159800

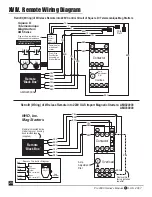

Magnetic Starter w/ Remote Option: 1 phase

1b. Motor Starter - AMR221417 1phase only

1c. Cord Connector - WWC027063 1 phase only

1d. Cord Connector Locknut - WCN340000 1 phase only

1e. 5hp Motor BMZ050170 - 1 ph / BMZ050370-3 ph

1f. Motor Plate - RMP002301

Magnetic Starter not factory wired 3 phase

Enclosed contactor with 220v coil - AMC183600

Overload 12-18 amps - AMO121800

Start Stop Push Button - AMP000000

2. Fan Housing - BHX030009

3. Cyclone Barrel - SXI002309

4. Cyclone Cone - SCX002309

5. Plenum Assembly for Filter 8 Elbow - FPX010300

5a. Thumb Nut (4) - AFT000001

5b. Cartridge Filter Threaded Clamp (4) - AFX000000

5b1. AFB155180 Bolt 5/16-18 x 2 1/2

5c. Fender Washer 5/16 (4) - AFW170000

5d. Dust Pan 4 - FPZ016040

5e. Hardware Kit - AHX000000

f1. (14) 3/8 Washers - AFW190000

f2. (7) 3/8 Wiz Nuts - AFT00004

f3. (7) 3/8 x 1 Bolts - AFS015100

f4. (12) 5/16 x 1 Bolts - AFB155190

f5. (24) 5/16 Washers - AFW180000

f6. (28) 5/16 Wiz Lock Nuts AFT155175

f7. Gasket - RGZ000000 (25)

f8. (3) 3/8 x 1 14 Bolts - AFS0157007

6. Internal Silencer (Pat. Pend.) - BSC180000

7. Filter - 18 Dia. x 62L - FCS186200

8. Owners Manual - ZBM000015

9. Decal - (1) Oneida Logo - ZBC000015

10. Labels

10a. Rotation Label - ZBC000029

10b. Caution / Exhaust Label - ZBS000004

10c. General Caution Label - ZBS000001

10d. Filter Maintenance Label - ZBS000007

10e. Caution / Check Frequently Label - ZBS000006

10f. Caution / Drum Cover Label - ZBS000005

11. Wall Bracket -Standard- SMS30000

12. Square to Round Inlet Transition to 8 dia. - BQX082000

Options for Dust Drums: OKD000000

13. 35 Gal. Fiber Drum Kit (Standard) - SDK351001

13a. Drum Lid w/ 10 Ring - SDX001000

13b. Hose Clamp 12 dia. (2) - ACB120000

13c. 35 Gal. Fiber Drum - SDS350000

13e. Flex Hose (10 dia. x 1) - DHF100000

13. 55 Gal. Fiber Drum Kit - SDK551001

13a. Drum Lid w/ 10 Ring - SDX001000

13b. Hose Clamps 12 (2) - ACB120000

13c. 55 Gal. Fiber Drum - SDS550000

13e. Flex Hose (10dia. x 1) - DHF100000

13. 55 Gal. Steel Drum Kit - SEK551001

13a. Drum Lid w/ 10 Ring - SEX551000

13b. Hose Clamps (2) - ACB120000

13c. 55 Gal. Steel Drum - SES550000

13e. Flex Hose (10 dia. x 1) - DHF100000

14.Filter Efficiency Gauge 0-5 H20 - VRG001005

14a. Vinyl Tubing Clear 5/16 O.D. - VRV003125 (8)

14b. Static Pressure Tip - VRP001875

14c. Mounting Flange for Pitot Tube - VRP010000

14d. Filter Efficiency Gauge Bracket - FXX000000

30. Optional 55 gal. Angle Iron Stand -

Part # STG023055

1. Uprights - SXX000068 (4)

2. Braces - SXX000021 (7)

3. Feet - STX002001 (4)

Stand - Hardware Kit -

Part # AHX021023

A. (32) - 5/16 Bolts

Part # AFB155190

B. (32) - 5/16 Wiz Nuts

Part # AFT155175

C. (64) 5/16 Flat Washers

Part # AFW180000

Optional Angle Iron Stand

0

1

2 3 4

5

INCHES W.C.

14 14a

14b

14d

14c

XXK200001 - 1 phase XXK200003 - 3 phase

f7

5

6

5a

5b

5c

7

f7

4

13b

13e

13b

13a

3

13c

5d

(8) 5/16 Washers

(8) 5/16 Nuts

(8) 5/16 Washers

(8) 5/16 Nuts

(7) 3/8 x 1 Bolts

(7) 3/8 Washers

(7) 3/8 Nuts

11

12

Optional Fan/Blower Outlet Transitions:

15. Square to 8 dia. For Fan Outlet - BQX308000 Uncrimped

15a. Square to 8 dia. For Fan Outlet - BQX308001 Crimped

2

1a

1e

1f

15 & 15a