7

The G9SX-SM

can be used for PL=e and Category 4 required by EN ISO 13849-1 European standard.

Refer to the following link for the Safety-related characteristic data:

http://www.fa.omron.co.jp/safety_6en/

This does NOT mean that G9SX-SM can always be used for required category under all the similar conditions and situations.

Conformity to the categories must be assessed as a whole system.

When using G9SX-SM for safety categories, be sure to confirm the conformity as a whole system.

For conformity to Safety Category 4, please check the following points;

1) Connect a fuse to each of the Standstill detection input lines.

2) Provide signals of different phases for the Standstill detection inputs (Z1-Z2, Z3-Z4).

3) Connect Guard lock Safety-door switches to any one of Safety Standstill detection outputs: ES1, ES2 or ES3.

4) Input the signal through a NC contact of the contactor to EDM input T31-T32. (Refer to '6. Application Examples')

5) Be sure to connect A2 to ground.

Performance Level and Safety category of EN ISO13849-1

Expected causes

Other

indicators

Checking points and measures to take

Faults

ERR

indicator

1) Failures involving the wiring of Standstill detection input 1

2) Inverter dynamic brake setting

3) Failures of the parts of the circuits of Standstill

detection input 1

1) Failures involving the wiring of Standstill detection input 2

2) Inverter dynamic brake setting

3) Failures of the parts of the circuits of Standstill

detection input 2

1) Check the disturbance level around

G9SX-SM and its related system.

2) Replace with a new product.

1) Check the wiring to Z1 and Z2.

2) Set the brake time at less than 30 seconds

3) Replace with a new product.

1) Check the wiring to Z3 and Z4.

2) Set the brake time at less than 30 seconds

3) Replace with a new product.

1) Frequency of standstill detection input is out of

range.

1) Confirm the operation frequency of the

motor is 120Hz or less.

1) Check the wiring to T31 and T32

2) Separately wire to T31 and T32 from the

power line etc., of the inverter.

3) Replace with a new product.

1) Failures involving the wiring of EDM input.

2) Excessive electro-magnetic disturbance

3) Failures of the parts of the circuits of EDM input

1) Incorrect set values of Standstill detection time

preset switches.

2) Failures of the parts of the circuits of mode settings.

1) Supply voltage outside the rated value

1) Confirm the set values of the two of

Standstill detection time preset switches.

2) Replace with a new product.

1) Check the supply voltage to G9SX units.

Fault by electro-magnetic

disturbance or of internal

circuits.

1) Excessive electro-magnetic disturbance

2) Failures of the parts of internal circuits

Faults involved with

Standstill detection input 1

Faults involved with

Standstill detection input 2

Faults involved with

Standstill detection input

Faults involved with

EDM input

Faults involved with

Safety Standstill detection

outputs

Faults involved with

Operation mode settings

Supply voltage outside

the rated value

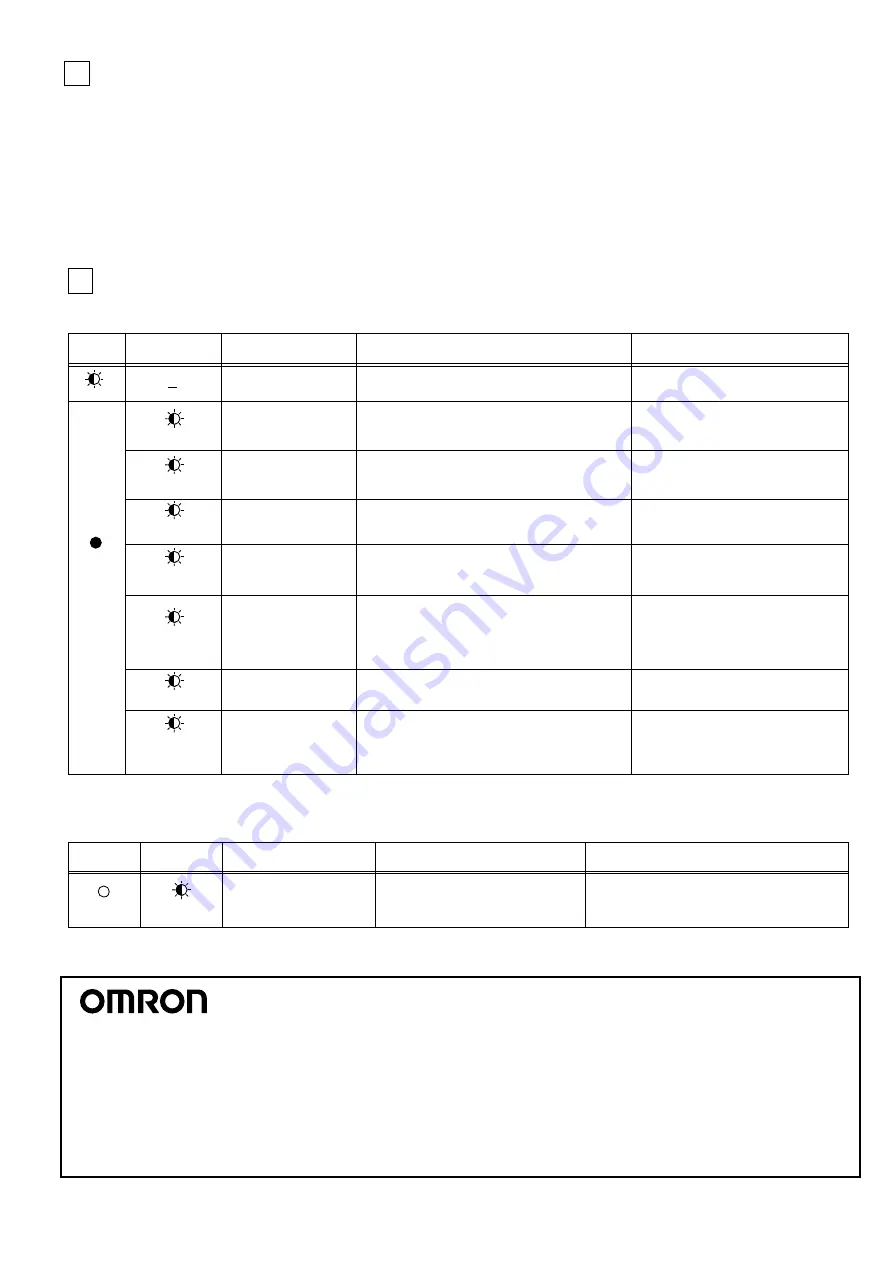

When G9SX-SM detects a fault, ERR indicator and/or other indicators light up or blink to show the information of the fault.

Check and take needed measures referring to the following table, and then apply supply voltage to G9SX-SM.

Fault Detection

8

Blink

CH1 Blink

Light

up

CH2 Blink

EDM Blink

CH1 and CH2

Blink at once

ES Blink

SET Blink

If any other indicator than ERR Indicator blinks, check and take needed actions referring to the following table.

ERR

indicator

Tuning mode operation

SET Blink

Light off

The other

indicators

Expected causes of the faults

1) Failures involving the wiring of Safety Standstill

detection outputs

2) Excessive electro-magnetic disturbance

3) Failures of the parts of the circuits of Safety

Standstill detection outputs

4) Impermissible high ambient temperature

1) Check the wiring to ES1, ES2 and ES3.

2) Separately wire to ES1, ES2 and ES3

from the power line etc. of the inverter.

3) Replace with a new product.

4) Check the ambient temperature and

spacing around G9SX-SM.

Conditions

Expected causes of the faults

Operating mode is in Tuning mode of

User configuration.

Check if the Operation preset switch and the Mode

preset switch on the back side are properly set.

In the User Configuration mode, Safety standstill

detection outputs will NOT be turned on.

The All

(without PWR)

indicators Blink

- 11 -

Note: Specifications subject to change without notice.

OMRON EUROPE B.V. (Importer in EU)

Wegalaan 67-69, NL-2132 JD Hoofddorp

THE NETHERLANDS

PHONE: 31-2356-81-300 FAX: 31-2356-81-388

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

PHONE: 1-847-843-7900 FAX: 1-847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

438A Alexandra Road # 05-05/08,

Alexandra Technopark Singapore 119967

SINGAPORE

PHONE: 65-6-835-3011 FAX: 65-6-835-2711

OMRON Corporation (Manufacturer)

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530

JAPAN

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower, 200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

PHONE 86-21-5037-2222 FAX 86-21-5037-2200