E5ZN-DRT

Features

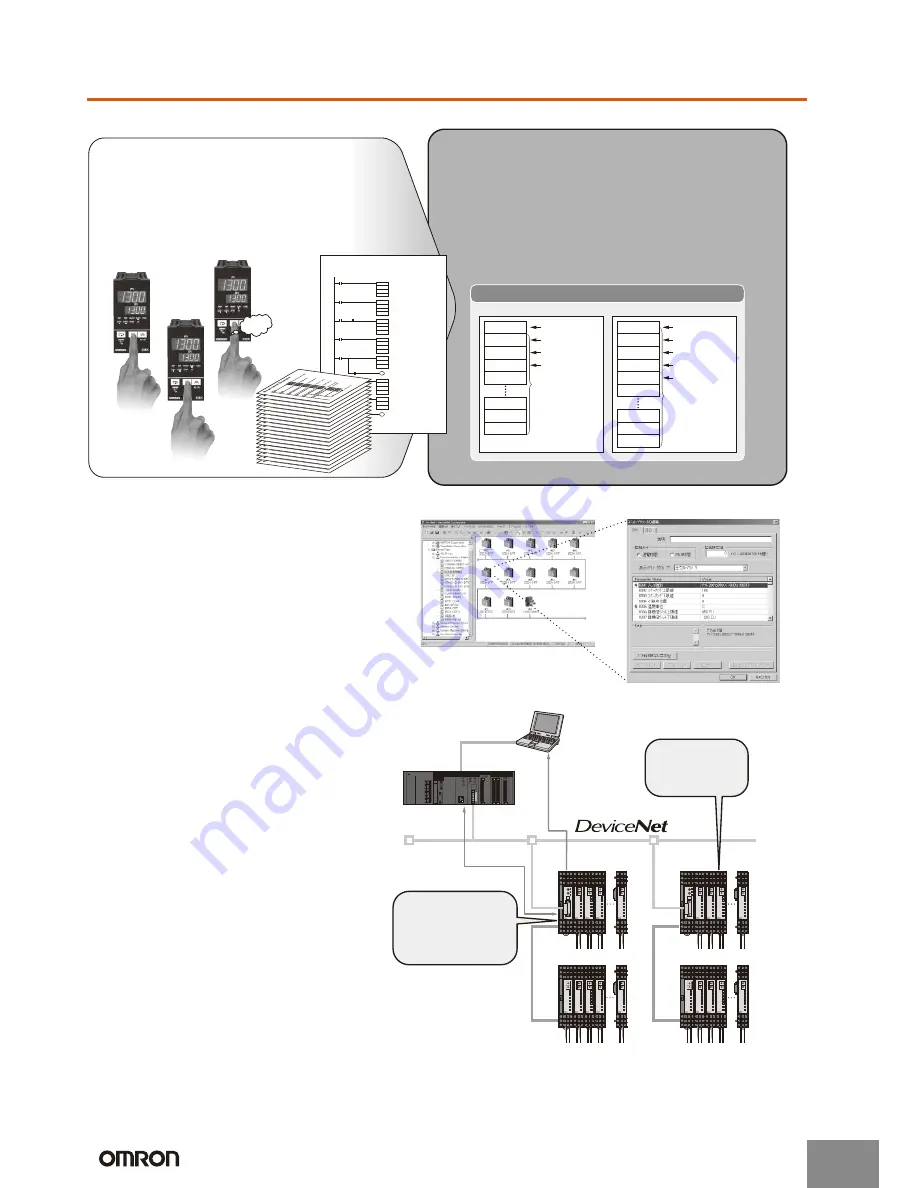

Startup Time Is Six Times Faster and No Communications Programs Are Needed

Manage All E5ZN Together from the DeviceNet Configurator

Improved Maintenance with Monitoring, Comment, and Copying Functions

Previously, a time-consuming process of creating

communications programs, debugging, and checking

operations was required for the Temperature Controller to

communicate with the PLC.

●

For example, setting 10 Units required 60 minutes.

●

Incorrect inputs were a concern.

●

Separate debugging for each Unit was needed.

DeviceNet Communications Units enable high-speed data

communications by allocating settings and monitoring

parameters in the PLCs I/O Memory Area, contributing to greater

reductions in the time required for communications program

development.

●

For example, set 10 Units in 10 minutes.

●

Batch download using the personal computer.

●

Debugging is easy using the personal computer.

Wd 0 and 1

Wd 2 and 3

Wd 4 and 5

Wd 6 to 37

OUT enabled

Control ON/OFF

AT executing

Set value (SV)

User-specified

allocations

are possible.

Wd 38

Wd 98

Wd 99

Wd 100

Wd 0 and 1

Wd 2 and 3

Wd 4 and 5

Wd 6 and 7

Comm status

Control ON/OFF

AT executing

Alarm output

User-specified

allocations

are possible.

Wd 38

Wd 8 to 37

Wd 98

Wd 99

Wd 100

Process value (PV)

OUT Area

IN Area

PLC Memory

NG

Beep

Beep

Beep

ASC

←

Converts SP data into ASCII.

←

Calculates FSC.

Trigger

DM000

K

Sd

FSC

Trigger

C

S

Sf

←

Sends command.

TDX

Trigger

S

C

N

Send Ready Flag

←

Receives response.

RXD

Receive Completion Flag

D

C

N

←

Checks end code.

Normal completion

CMP

Receive Completion Flag

De

#3030

←

Checks FCS.

FCS check OK

FCS

Receive Completion Flag

C

D

D'f

CMP

Df

D'f

No-protocol Example

D'f

Use the DeviceNet Configurator for E5ZN

initial settings and temperature control wiring

to enable immediate execution.

DeviceNet

Master

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

E5ZN

●

Measure the heater control time (RUN

time monitor) to manage heater life

expectancy.

●

Monitor supply voltages, such as those

for Temperature Controller and

Communications Unit power supplies,

and network power supplies.

●

User-specified names can be set for

each heater and Communications Unit,

enabling the location of errors to be

checked quickly.

●

Upload/download Temperature Controller

parameters to the Communications Unit.

This shortens the time required to

replace Temperature Controllers.

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

E5ZN

ERROR

E5ZN-SCT24S

SD/RD

OUT 1

OUT2

SUB 1

SUB2

Maintenance data

Control data

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

ERROR

SD/RD

OUT 1

OUT2

SUB 1

SUB2

E5ZN

POWER

BPS

UNIT

E5ZN

ERROR

E5ZN-SCT24S

SD/RD

OUT 1

OUT2

SUB 1

SUB2

DeviceNet

Configurator

Check the actual

operating time

of the heater.

Check the settings

for the heater of

oven No. 3.

http://www.ia.omron.com/

2

(c)Copyright OMRON Corporation 2007 All Rights Reserved.