TYPE 3G3RX-

-V1

High-function General-purpose Inverter

NT205XG

Cat.No.

Manual Name

INSTRUCTION MANUAL

Thank you for purchasing 3G3RX, V1 type Inverter.

To ensure safe operation, please be sure to read the safety precautions

provided in this document along with all of the user manuals for the

inverter. Please be sure you are using the most recent versions of the

user manuals. Keep this instruction manual and all of the manuals in a

safe location and be sure that they are readily available to the final user

of the products.

OMRON Corporation

3G3RX User’s Manual

Safety Precautions

I578-E1

OMRON Corporation 2012 All Rights Reserved.

Indications and Meanings of Safety Information

Meanings of Signal Words

Alert Symbols in this Document

In this user’ s manual, the following precautions and signal words are

used to provide information to ensure the safe use of the 3G3RX, V1 type

Inverter.The information provided here is vital to safety. Strictly observe

the precautions provided.

WARNING

Indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate

injury or in property damage.

CAUTION

Indicates an imminently hazardous situation which,

if not avoided, is likely to result in serious injury or

may result in death. Additionally there may be severe

property damage.

Turn off the power supply and implement wiring correctly.

Not doing so may result in a serious injury due to an electric shock.

WARNING

Be sure to ground the unit. Not doing so may result in a serious injury

due to an electric shock or fire.

(200V class:type-D grounding, 400V class:type-C grounding)

Do not remove the terminal cover during the power supply and 10

minutes after the power shut off.

Doing so may result in a serious injury due to an electric shock.

Do not operate the Operator or switches with wet hands.

Doing so may result in a serious injury due to an electric shock.

Inspection of the Inverter must be conducted after the power supply has

been turned off. Not doing so may result in a serious injury due to an

electric shock.

The main power supply is not necessarily shut off even if the emergency

shut off function is activated.

Wiring work must be carried out only by qualified personnel.

Not doing so may result in a serious injury due to an electric shock.

Do not touch the Inverter fins, braking resistors and the motor, which

become too hot during the power supply and for some time after the

power shut off. Doing so may result in a burn.

Do not change wiring and slide switches (SW1), put on or take off

Operator and optional devices, replace cooling fans while the input

power is being supplied. Doing so may result in a serious injury due to

an electric shock.

CAUTION

The Inverter has high voltage parts inside which, if short-circuited, might

cause damage to itself or other property. Place covers on the openings

or take other precautions to make sure that no metal objects such as

cutting bits or lead wire scraps go inside when installing and wiring.

Be sure to use a specified type of braking resistor/regenerative braking

unit. In case of a braking resistor, install a thermal relay that monitors

the temperature of the resistor. Not doing so might result in a moderate

burn due to the heat generated in the braking resistor/regenerative

braking unit. Configure a sequence that enables the Inverter power to

turn off when unusual over heating is detected in the braking resistor/

regenerative braking unit.

Do not connect resistors to the terminals (+1, P/+2, N/-) directly. Doing

so might result in a small-scale fire, heat generation or damage to the

unit.

Do not dismantle, repair or modify the product.

Doing so may result in an injury.

Take safety precautions such as setting up a molded-case circuit breaker

(MCCB) that matches the Inverter capacity on the power supply side.

Not doing so might result in damage to property due to the short circuit

of the load.

Install a stop motion device to ensure safety. Not doing so might result in

a minor injury. (A holding brake is not a stop motion device designed to

ensure safety.)

Do not store or use the product in the following places.

Locations subject to direct sunlight.

Locations subject to ambient temperature exceeding the specifications.

Locations subject to relative humidity exceeding the specifications.

Locations subject to condensation due to severe temperature fluctuations.

Locations subject to corrosive or flammable gases.

Locations subject to exposure to combustibles.

Locations subject to dust (especially iron dust) or salts.

Locations subject to exposure to water, oil, or chemicals.

Locations subject to shock or vibration.

Installation and Storage

Precautions for Safe Use

Do not drop or apply strong impact on the product. Doing so may result

in damaged parts or malfunction.

Do not hold by the front cover and terminal cover, but hold by the fins

during transportation.

Confirm that the rated input voltage of the Inverter is the same as AC

power supply voltage.

Do not connect an AC power supply voltage to the control input/ output

terminals. Doing so may result in damage to the product.

Be sure to tighten the screws on the terminal block securely.

Wiring work must be done after installing the unit body.

Do not connect any load other than a three-phase inductive motor to

the U, V, and W output terminals.

Take sufficient shielding measures when using the product in the

following locations. Not doing so may result in damage to the product.

Locations subject to static electricity or other forms of noise.

Locations subject to strong magnetic fields.

Locations close to power lines.

If a parameter is set incorrectly when starting up, adjusting, maintaining,

or replacing, an unexpected operation may occur.

Perform the operation after enough confirmation.

When using DriveProgramming, confirm that the program data is

downloaded normally before starting the operation.

Operation and Adjustment

Maintenance and Inspection

Transporting, Installation, and Wiring

Be sure to confirm the permissible range of motors and machines before

operation because the inverter speed can be changed easily from low to

high.

Provide a separate holding brake if necessary.

If DriveProgramming stops during multi-function output, the output status

is held. Take safety precautions such as stopping peripheral devices.

If the clock command is used in DriveProgramming, an unexpected

operation may occur due to weak battery or removal of the LCD digital

operator.

Take measures such as detecting a weak battery or removal of the LCD

digital operator (the clock data detects the initial setting and all zero),

stopping the Inverter or programs.

Be sure to confirm safety before conducting maintenance, inspection or

parts replacement.

The capacitor service life is influenced by the ambient temperature.

Refer to "Product Life Curve" described in the manual. When a capacitor

reaches the end of its service life and does not work as the product, you

need to replace the capacitor.

When disposing of LCD digital operators and wasted batteries, follow

the applicable ordinances of your local government.

When disposing of the battery, insulate it using tape.

The following display must be indicated when products using lithium

primary batteries (with more than 6 ppb of perchlorate) are transport to

or through the State of California, USA.

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

The 3G3AX-OP05 has the lithium primary battery (with more than 6 ppb

of perchlorate).Label or mark the above display on the exterior of all

outer shipping packages of your products when exporting your products

which the 3G3AX-OP05 are installed to the State of California, USA.

Do not short + and -, charge, disassemble, heat, put into the fire, or

apply strong impact on the battery. The battery may leak, explode,

produce heat or fire. Never use the battery which was applied strong

impact due to such as fall on the floor, it may leak.

UL standards establish that the battery shall be replaced by an expert

engineer.

The expert engineer must be in charge of the replacement and also

replace the battery according to the method described in this manual.

When the display of LCD digital operator can not be recognized due to

the service life, replace the LCD digital operator.

Precautions for Safe Use

Installation

Restart Selection Function

Deceleration Stop Function

Operation Stop Command

Maintenance and Parts Replacement

Product Disposal

Mount the product vertically on a wall the product’ s longer sides upright.

The material of the wall has to be noninflammable such as a metal plate.

Do not come close to the machine when using the Restart Selection

function (b001, b008) because the machine may abruptly start when

stopped by an alarm.

Be sure to confirm the RUN signal is turned off before resetting the

alarm because the machine may abruptly start.

Do not come close to the machine when selecting reset in the

Deceleration Stop Function (b050) because the machine may abruptly

start after the power is turned on.

Provide a separate emergency stop switch because the STOP Key on

the Operator is valid only when function settings are performed.

When checking a signal during the power supply and the voltage is

erroneously applied to the control input terminals, the motor may start

abruptly. Be sure to confirm safety before checking a signal.

Inverters contain components and will operate properly only when each

component operates normally. Some of the electrical components

require maintenance depending on application conditions.

Periodic inspection and replacement are necessary to ensure proper

long-term operation of Inverters. (Quoted from The Recommendation for

Periodic Maintenance of a General-purpose Inverter published by JEMA.)

When a cooling fan reaches the end of its service life, replace it.

Comply with the local ordinance and regulations when disposing of the

product.

UL Cautions

The warnings and instructions in this section summarize the procedures

necessary to ensure an inverter installation complies with Underwriters

Laboratories guidelines.

These devices are open type AC Inverters with three phase input and

three phase output. They are intended to be used in an enclosure. They

are used to provide both an adjustable voltage and adjustable frequency to

the AC motor. The inverter automatically maintains the required voltage-Hz

ration allowing the capability through the motor speed range.

Use 60/75°C Cu wire only. For models 3G3RX-V1 series except for

models 3G3RX-A4055-V1, 3G3RX-A4075, 3G3RX-A4110-V1.

Use 75°C Cu wire only. For models 3G3RX-V1 series for

3G3RX-A4055-V1, 3G3RX-A4075, 3G3RX-A4110-V1.

Suitable for use on a circuit capable of delivering not more than 100k rms

symmetrical amperes, 240 V maximum. (For models: 200 V class)

Suitable for use on a circuit capable of delivering not more than 100k rms

symmetrical amperes, 480 V maximum. (For models: 400 V class)

Install device in pollution degree 2 environment.

Maximum Surrounding Air Temperature 50°C (VT rating is 40°C).

Caution -Risk of Electric Shock- Capacitor discharge time is at least 10

minutes.

Solid state motor overload protection reacts with max. 120% of FLA.

Integral solid state short circuit protection dose not provide branch circuit

protection.

Branch circuit protection must be provided in accordance with the NEC

and any additional local codes.

Motor over temperature protection is not provided by the drive.

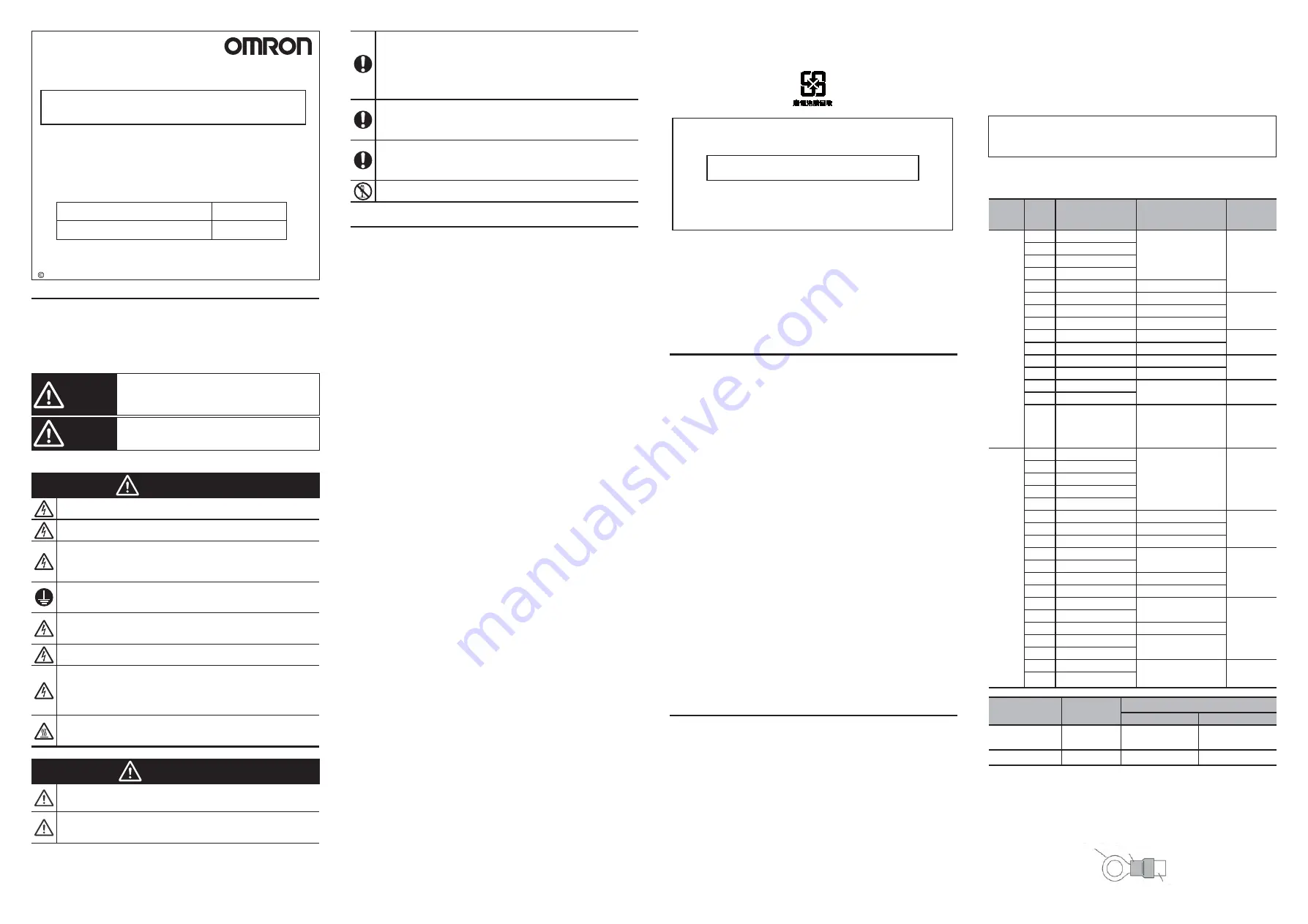

Terminal Tightening Torque and Wire Size

The wire size range and tightening torque for field wiring terminals are

presented in the tables below.

Input

Voltage

Motor

Output

(kW)

Inverter Model

3G3RX-

Power Terminal

Wiring Size Range

(AWG)

Torque

(N·m)

0.4

0.75

A2004-V1

A2007-V1

1.5

A2015-V1

2.2

A2022-V1

3.7

A2037-V1

350 kcmil (Prepared

wire only) or Parallel

of 2/0 (Prepared wire

only)

14(Stranded only)

10(Stranded only)

5.5

A2055-V1

8

7.5

A2075-V1

6

11

A2110-V1

6 or 4

15

A2150-V1

2

22

A2220-V1

1 or 1/0

30

A2300-V1

2/0 or Parallel of 1/0

37

A2370-V1

45

A2450-V1

55

A2550-V1

4/0 (Prepared wire

only) or Parallel of 1/0

18.5

A2185-V1

1

1.8

4.0

4.9

8.8

20.0

19.6

200V

Class

400V

Class

0.4

0.75

A4004-V1

A4007-V1

1.5

A4015-V1

2.2

A4022-V1

3.7

A4037-V1

14(Stranded only)

5.5

A4055-V1

12

7.5

A4075-V1

10

11

A4110-V1

8

15

A4150-V1

6

22

A4220-V1

6 or 4

30

A4300-V1

3

37

A4370-V1

45

A4450-V1

55

A4550-V1

1

2/0

75

B4750-V1

Parallel of 1/0

Parallel of 3/0

90

B4900-V1

110

B411K-V1

132

B413K-V1

18.5

A4185-V1

1.8

4.0

4.9

20.0

35.0

Terminal

Connector

Logic and Analog

connectors

Wiring Size

Range(AWG)

Torque

30~16

30~14

0.16~0.19

0.22~0.25

0.5~0.6

0.37~0.44

Ft·Ibs

(N·m)

Relay connector

Wire Connectors

Field wiring connections must be made by a UL Listed and CSA certified

closed-loop terminal connector sized for the wire gauge involved.

Connector must be fixed using the crimp tool specified by the connector

manufacturer.

Terminal

Cable support

Cable

0194437-6C

AVERTISSEMENT: ne retirez pas le capot avant pendant l’alimentation

et 10 minutes après l’arrêt de l’alimentation. Cela peut entraîner de

grave blessure due à un choc électrique.