Cod. 710.0138.01.00 Rev04A

– 03.2017

© Copyright 2017 OMI Srl - All rights reserved

9

– 12

TROUBLE

DISPLAY

POSSIBLE CAUSE

REMEDY

WAT

ER IN T

HE SYSTEM

Control panel

display is

blank

No power in the line.

Restore the power in the line.

ED780-1000

Phases connected incorrectly.

Connect the phases correctly.

Problems with cabling.

Check cabling; if the trouble persists, replace it.

Problems with the electronic control board.

Check the electronic control board; if the trouble persists,

replace it.

The dryer is off.

Turn it on by pressing the ON/OFF switch for 1 second.

Dryer in stand-by.

Wait 2 minutes after the dryer is switched on.

Compressed air inlet/outlet inverted.

Check if the compressed air inlet/outlet is connected

properly.

The flow rate and/or temperature of the air

entering the dryer are higher than the

nominal values.

Restore the nominal conditions.

The ambient temperature is higher than the

nominal values.

Restore the nominal conditions.

The condenser is dirty.

Clean the condenser.

Condensate drain is not functioning.

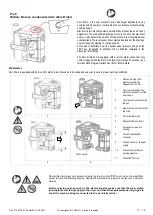

Pic.3

Clean the condensate drainage system filter mesh.

Replace the coil of the drainage solenoid valve if burned.

Clean or replace the drainage solenoid valve if

clogged/jammed.

Check the C8 and C9 parameters of the electronic control

board; if the trouble persists, replace it.

Condensate drain is not functioning.

Pic.4-5

Check the no loss condensate drain; if the trouble persists,

replace it.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

ED780-1000

Intervention of the high pressure switch.

Reset the high pressure switch.

Problems with cabling or with the electronic

control board.

Check the cabling and the electronic control board, if the

trouble persists, replace them.

Activation of compressor’s internal thermal

protection.

Wait one hour and check again. If the fault persists: stop

dryer and call your localOMI distributor.

Problems with the electrical components of

the compressor.

Check the electrical components of the compressor.

Defective compressor.

Replace the compressor.

The flow rate and/or temperature of the air

entering the dryer are higher than the

nominal values.

Restore the nominal conditions.

The ambient temperature is higher than the

nominal values.

Restore the nominal conditions.

The condenser is dirty.

Clean the condenser.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

Fan pressure switch defective or burned out

(if present).

Turn off the dryer and call your localOMI distributor.

High pressure switch defective or burned out

(if present).

Turn off the dryer and call your localOMI distributor.

Gas leakage in the refrigerating circuit.

Turn off the dryer and call your localOMI distributor.

Defective fan.

Replace the fan.

Protection fuse burned out (if present).

Replace the fuse.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

Gas leakage in the refrigerating circuit

without load.

Turn off the dryer and call your localOMI distributor.

The temperature control probe is positioned

improperly or faulty.

Check the probe; if the trouble persists, replace it.

Series of alarms very close to each other.

Call your localOMI distributor.