3

BEFORE USE

1. Verify that the product and the application are

compatible, if in doubt call Omega Technical Service

(888)332-6419.

2. Before using this product, read the operator's

manual completely and familiarize yourself

thoroughly with the product, its components and

recognize the hazards associated with its use.

3. Locate and open the release valve

(counterclockwise no more than 1/2 full turn).

4. With saddle fully lowered, locate and remove the oil

filler plug. Secure the handle into the handle sleeve,

then pump 6 to 8 full strokes. This will help release

any pressurized air which may be trapped within the

reservoir. Ensure the oil level is ~3/16" above the

inner cylinder as seen from the oil filler plug hole.

Re-install the oil filler plug.

5. Check to ensure that jack rolls freely and that the

pump operates smoothly before putting into service.

Replace worn or damaged parts and assemblies

with Omega Authorized Replacement Parts only.

(See Replacement Parts Section). Lubricate as

instructed in Maintenance Section.

6. Inspect before each use. Do not use if bent, broken

or cracked components are noted.

OIPM#25048- SJ2

WARNING

!

To avoid crushing and related injuries:

NEVER work on, under or around a load supported

only by a jack. ALWAYS use adequately rated jack

stands.

Lift only on areas of the vehicle as specified by the

vehicle manufacturer. Do not use adapters or

accessories that are not provided initially.

! SAFETY MESSAGE !

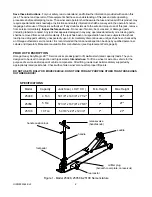

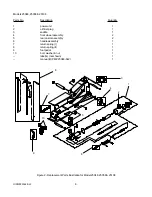

ASSEMBLY

Little, if any, assembly is required of these jacks.

Always secure the handle into the handle fork by

means of the bolt and lock washer provided. Tighten

securely to prevent accidental removal of handle while

in use. Familiarize yourself with the illustrations in the

operator's manual. Know your jack and how it operates

before attempting to use.

OPERATION

Lifting

1. Place vehicle in park, with emergency brake on and

wheels securely chocked to prevent inadvertent

vehicle movement.

2. Locate and close release valve by turning handle

knob clockwise, firmly. Center jack saddle under lift

point.

3. Verify lift point, then pump handle to contact lift

point. To lift, pump handle until load reaches desired

height.

4. Transfer the load immediately to appropriately rated

jack stands.

Lowering

1. Raise load high enough to clear the jack stands,

then carefully remove jack stands (always used in

pairs).

2. Slowly turn the handle knob counterclockwise, but

no more than 1/2 turn. If the load fails to lower:

a. Use another jack to raise the vehicle high

enough to reinstall jack stands.

b. Remove the affected jack and then the stands.

c. Using the other jack, lower the load by turning

the handle knob counterclockwise, but no more

than 1/2 turn.

3. After removing jack from under the load, push

saddle down to reduce ram exposure to rust and

contamination.

Study, understand, and follow all instructions

provided with and on this device. Do not exceed

rated capacity. This is a lifting device only. After

lifting, immediately transfer the load to

appropriately rated vehicle stands. Never work on,

under, or around a load supported by this device.

Use only on hard, level surfaces capable of

sustaining rated capacity loads. Do not move or

dolly loads with this device. Do not modify this

device. Failure to heed these markings may result

in personal injury and/or property damage.

!

WARNING