4

TROUBLESHOOTING

Symptom

Possible Causes

Corrective Action

Jack will not lift load

• Release Valve not tightly closed

• Overload condition

• Ensure Release Valve is tightly closed

•

Remedy overload condition

Jack will lift, but not maintain

pressure

•

Release Valve not tightly closed

•

Hydraulic unit malfunction

•

Ensure Release Valve is tightly closed

•

Contact Omega Lift Technical Service

Jack will not lower after unloading

• Reservoir overfilled

• Ensure load is removed, then drain

fluid to proper level

Poor lift performance

• Fluid level low

•

Air trapped in system

• Ensure proper fluid level

•

Follow

Bleeding/Venting Trapped

Air

procedure on page 3

Will not lift to full extension

• Fluid level low

•

Ensure proper fluid level

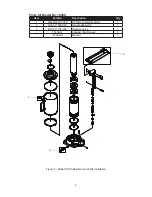

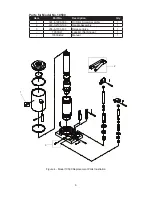

REPLACEMENT PARTS

Please refer to the Parts drawing when ordering parts. Not all components of the jack are replacement items, but

are illustrated as a convenient reference of location and position in the assembly sequence. Call or write for current

pricing: SFA Companies Inc. 10939 N. Pomona Ave. Kansas City, MO 64153, U.S.A. Tel:(888)332-6419

Fax:(816)891-6599 e-mail:[email protected] Omega Lift Website: http://www.omegalift.com

!

Lubrication

1. A coating of light lubricating oil to pivot points, axles

and hinges will help to prevent rust and assure that

wheels, casters and pump assemblies move freely.

2. Periodically check the pump piston and ram for

signs of rust or corrosion. Clean as needed and

wipe with a clean, oil soaked rag.

CAUTION:

Never use sandpaper or abrasive

material on these surfaces !

Storage

When not in use, store the jack with pump piston and

ram fully retracted.