8

3.0 FURNACE INSTALLATION

The installation of the appliance shall be in accordance with the regulations of the authorities having

jurisdiction.

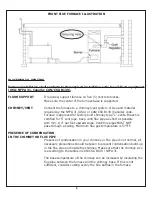

OIL TANK PIPING

Tank installation must conform to local requirements.

Install according to the applicable code such as CAN/CSA B139 and NFPA 31 in the USA.

Minimize number of connections in suction line and make all connections air tight. Use a pipe

joint compound suitable for oil on all pipe threads. To reduce possibility of air leaks, tighten

stem packing gland nut on any valves installed in the suction line. Also, be sure the oil filter is tight,

as filter gaskets often shrink. Check for kinks in the oil lines as well as for possible air pockets and

for loose connections. Two filters as shown below are recommended. Optional tank gauge

protectors and outlet protectors are available at your local dealer.

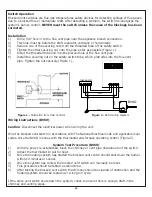

ONE PIPE SYSTEM

Where the tank outlet is above the burner and when the oil flows by

gravity to the oil pump, a single-stage fuel unit with a single oil line to

the pump may be used.

TWO PIPE SYSTEM

When a single line is not suitable, use two-line system. Install by-pass

plug on burner fuel pump as specified in the burner manual.