4

materials to come into contact with the furnace.

5. Any additions, alterations or conversions re-

quired in order for the furnace to properly match the

application requirements must be done by a quali-

fi ed installation contractor, service agency or gas

supplier, using factory specifi ed or approved parts.

6. Familiarize yourself with the location of the fur-

nace gas manual shut-off valve and any electrical

switches, fuse or circuit breaker associated with

the furnace.

7. Should over-heating occur, or if the gas valve

fails to shut off the burners, shut off the gas supply

with the furnace manual shut-off valve, then shut

off the electrical supply to the furnace. In the case

of the latter, call a qualifi ed installation contractor,

service contractor, or gas supplier.

8. If the furnace has been subjected to fl ood condi-

tions, i.e., if any part of the furnace has been under

water, call a qualifi ed installer, service agency or

gas supplier for a complete inspection. Electronic

controls and gas train components may become

unstable and unreliable. The furnace must not be

used until the furnace has been checked, and any

affected parts have been replaced.

9. Do not allow snow, ice or debris to accumulate

around the outdoor furnace exhaust and combus-

tion air intake terminals. Blockage of the exhaust

or combustion intake terminals can result in inad-

equate performance or nuisance shut-downs.

10. Familiarize yourself with the location of your

furnace fi lter or fi lters. A blocked air fi lter will reduce

effi ciency, increase fuel consumption, raise the fur-

nace operating temperature, and shorten the life of

furnace components.

11. Do not cover return air grills and supply air reg-

isters with drapes, curtains, throw rugs, etc.

12. Avoid shutting off supply air registers in the

interests of saving heat. While there is some va-

lidity to this practice with space heating, there is

little to be gained in central heating systems. The

furnace requires a quantity of air passing over the

heat exchanger to operate within design tempera-

tures. Reducing the number of supply air registers

available for air delivery may have the unforeseen

consequence of raising the furnace operating tem-

perature, reducing furnace effi ciency, and shorten-

ing the life of the furnace components.

3 - FURNACE OPERATION INFORMATION

During the heating season, the operation of the fur-

nace is fully automatic.

TO START THE FURNACE:

1. First read these instructions and safety no-

tices thoroughly.

2. Set the thermostat to the lowest setting.

3. Ensure that all supply air registers and return

air grilles are open.

4. Turn off the electric power to the furnace.

5. Remove the burner access door.

6. Ensure that the appliance manual shut-off

valve is in the “ON” position. The valve handle is

normally in-line with the gas pipe and valve body

when it is in the “ON” position; perpendicular to

the gas piping and valve body when it is in the

“OFF” position.

7. Turn the manual gas control switch to the

“OFF” position.

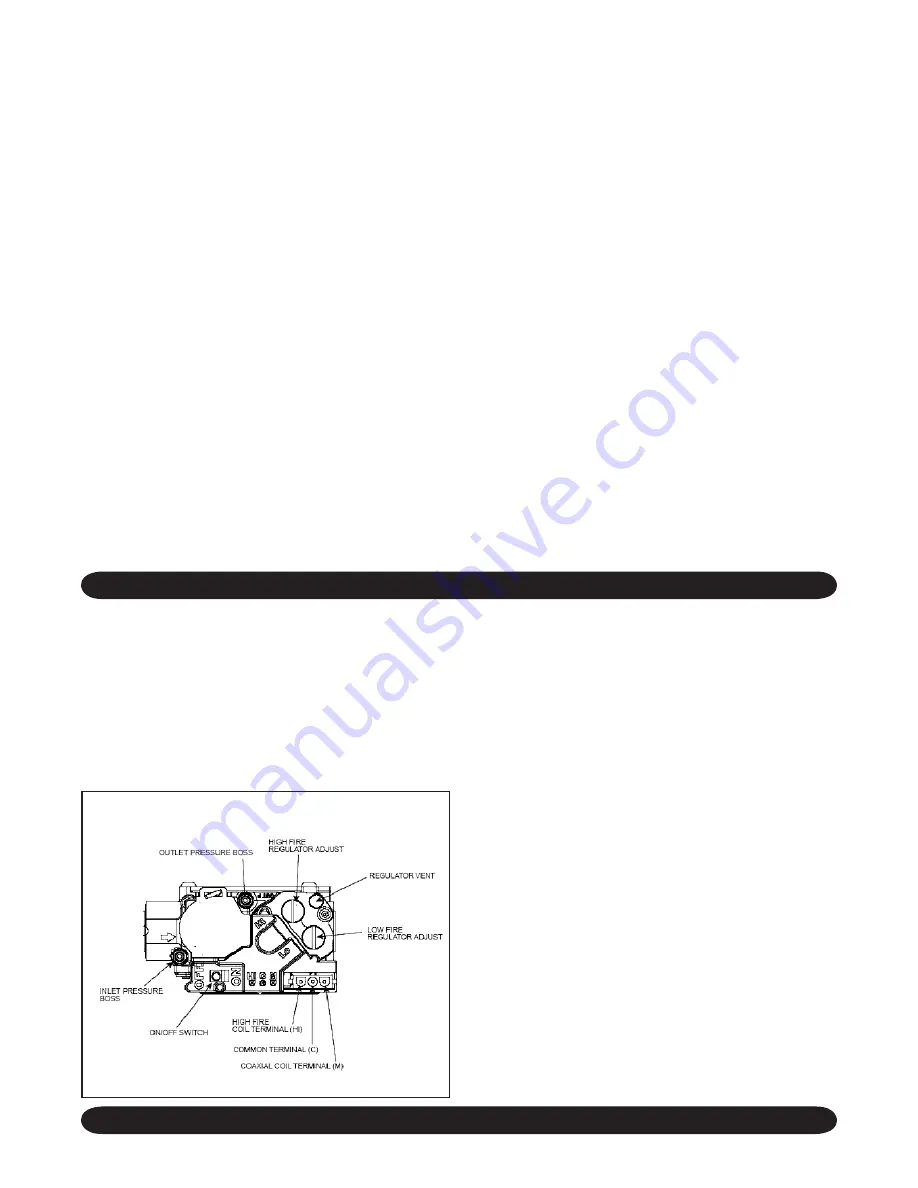

(Figure 3)

8. Wait 5 minutes to clear out any gas. If, after

this time you smell gas, STOP. Turn the appli-

ance manual shut-off valve to the “OFF” posi-

tion. If burning propane or other LP gas, smell

for gas near the fl oor since propane and butane

are both heavier than air. If after this time you do

not smell gas, continue to the next step.

FIGURE 3 - WHITE-RODGERS 36G54 GAS VALVE