5-12

XYAA6338

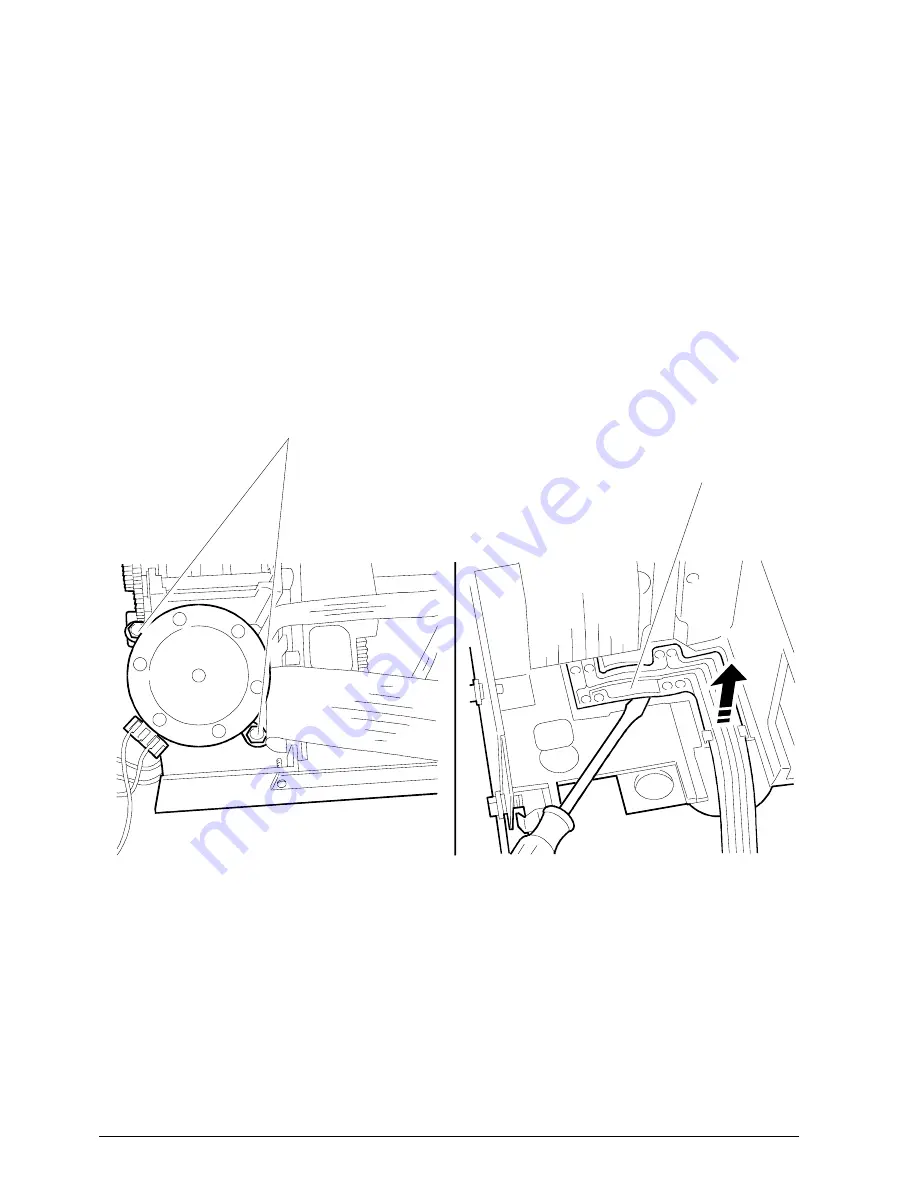

CARRIAGE MOTOR

SECURING SCREWS

Fig. 5-10

Fig. 5-11

PHOTOSENSORS

5.9 REMOVING THE DOCUMENT

DETECTION PHOTOSENSORS

•

Remove the case (Section 5.2).

•

Remove screws 1 and 2 (Sections 5-4) and then

disconnect all the connectors from the electronic

board so that the machine can be separated from

the base.

•

Remove the carriage motor (Section 5.7) as shown

in Figure 5-10.

•

Remove the photosensors by extracting them

from their slots with a screwdriver (Figure 5-11).