E-22

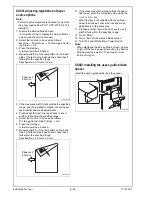

19. Check whether the difference in the width A

between the chart and the copy sample is within

the specified range.

Difference in the width A = A of the copy sample

– A of the chart

Specifications: 0 ± 2.0 mm

* If the difference in the width A does not fall within

the specified range, perform the following

adjustment.

20. Display the Service Mode screen.

(For details of how to display the Service Mode

screen, see the service manual.)

21. Touch “ADF.”

22. Touch “Original Stop Position.”

23. Touch “Main Scanning (Front)” or “Main Scan-

ning (Back).”

24. While looking at the copy sample, enter a value

using the ten-key pad. (To switch the signs,

press the +/- key.)

Adjustable range: -4.4 mm to +4.4 mm

(0.1 mm per step)

If the difference in the width A is greater than the

specifications, enter a positive (+) value.

If the difference in the width A is smaller than the

specifications, enter a negative (-) value.

25. Touch “END.”

26. Touch “Exit” on the Service Mode screen.

27. Turn OFF and ON the Main Power Switch.

Note:

When displayed the Service Mode screen, be sure

to turn off the main power after exiting the Service

Mode screen and wait for 10 seconds or more

before turning on.

28. Make copies again and check the difference in

the width A.

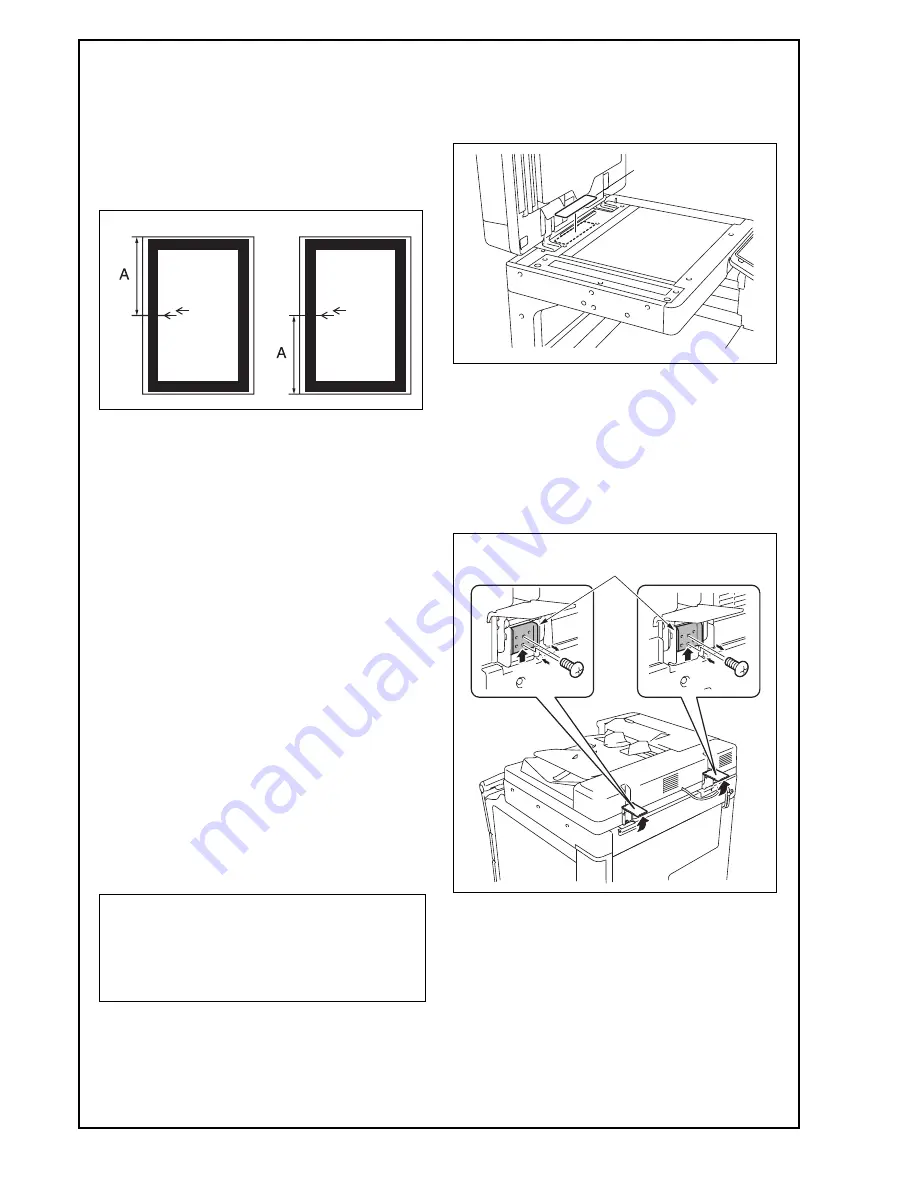

XXVI. Affixing the label (Legal restrictions

on copying)

Affix the label (Legal restrictions on copying) to the

position shown below.

XXVII. Changing the stopper position

1. Raise the two hinge covers on the back of the

dual scan document feeder and remove the stop-

per from the hinge of the dual scan document

feeder.

2. Change the set position of the stopper to the

upper side and secure it in position.

Note:

When the dual scan document feeder/reverse

automatic document feeder is adjusted in ser-

vice mode, “Adjustments list” should be output

again as necessary. (Refer to E-14 “XIX. List

output.”)

A1DMIXC019DA

A1DMIXC016DA

<Front>

<Back>

A2XKIXE030DA

Label

A3CEIXE047DA

Stopper

Installation Manual

Y115290-3